a writing from user “韭菜和瓜子” from 中国芯吧

chatgpt translation:

the current situation as far as I know:

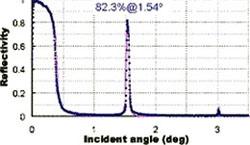

1. Most of the equipment for the 28nm process node can now be domestically produced. The main obstacle is the arfi duv lithography machine for the 28nm node. The initial prototype of this machine was taken offline in March 2022, and several units were produced by the manufacturer's laboratory and sent to some fabs for testing. According to sources, although it is a 28nm machine, testing must start from the 65nm process node, followed by 55nm, 45nm, and finally 28nm, progressing step by step. The current progress is unclear, but it is certain that the initial testing of the 55nm process node was achieved in the first quarter. These processes are very rigorous and must follow scientific principles. The sources also indicate that even for giants like ASML, it takes at least a year, if not more, to debug and optimize their new generation machines, whether it's DUV or EUV. The earliest possibility for the 28nm machine production line to be fully operational is the end of this year, while a slower timeline could be around mid-2024. The manufacturer is confident in their machine. Currently, the manufacturer's dry DUV machines are already in mass production and performing well with high demand. As a result, the manufacturer has started expanding production lines to prepare for mass production of arfi duv machines. According to sources, the expanded capacity will be 20 units per year.

2. 2. There is no fear of existing sanctions on machine equipment because some stockpiles have been accumulated in recent years. Even if there is an immediate complete decoupling from all Western countries, it would still be possible to sustain until domestic production of lithography machines is achieved.

3. The entire industry chain is not only focused on domesticating the machines but also localizing the machine components. Everyone is working diligently, and the progress is considerable. However, this does not mean that 100% completion has been achieved at the current stage. Fortunately, major domestic equipment manufacturers have also stockpiled many components in advance. Additionally, many of the components that have not been localized are general components, such as pipes, valves, pumps, seals, etc., which are not specifically developed for semiconductor equipment but widely used in various industrial equipment. These are the weak points of our industry, and many of these components are used in semiconductor equipment. However, since they are general supplies, it is difficult to impede their supply. Establishing a shell company or purchasing them in a third country is always an option.

4. Efforts are being made to address materials, electronic special gases, and semiconductor wet chemicals. The difficulty is, of course, less than that of machines, but there are hundreds of different types of materials and chemicals involved. For example, just for the arfi duv lithography resist, there are 20 or 30 types. Two years ago, Nanjing University of Science and Technology claimed to have sent two types of arf duv lithography resists for testing, which was merely an attempt to deceive outsiders. I previously posted a thread about lithography resists in the forum, and you can refer to that.

5. Process control software, robotic arms, mechanical hands, AMHS systems, and other related equipment are being developed by domestic manufacturers.

In summary, by 2025, a complete domestically produced 28nm production line can be established. After that, upgrades are planned every 12 months (not following Moore's Law's 18-month cycle), taking advantage of a late start and a determined technological direction without the need for exploration. In 2026, there will be a 14nm production line, followed by a 10nm line in 2027, and a 7nm line in 2028. The progress of EUV machines and EUV resists will become critical at that point, as other equipment is generally available.