1 kT of photoresist, not too bad, not too much. Entire production volume of Taiwanese photoresist, for instance, is 20 kT.Looks like Shanghai Sinyang has been doing some Q&A and there are interesting answers here

This is interesting. The Arf photoresist that's getting verified by customers is capable of being used in 7nm process.

So between Shanghai base and Hefei base, they believe they can reach 1000t of photoresist a year by end of this decade. That seems a lot. Earlier this thread, I saw the post that says they only have 50t of photoresist capacity right now. This would 20x their production.

They are saying here that Krf is already getting sold and replacing imports.

For others, what is the leading photoresist producer producing per year? Is 1000t a year a lot? @tokenanalyst @FairAndUnbiased

Looks like Hefei's plant has yet to enter production. Maybe they are experiencing equipment delays or maybe they are waiting on validation.

looks like the reported 10k ton of photoresist thinner material is for photoresist re-agent material.

people are questioning about their huge expansion plans, I guess they are quite ambitious. Considering that 90% of this is imported (IIRC), a lot of room for growth here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese semiconductor industry

- Thread starter Hendrik_2000

- Start date

- Status

- Not open for further replies.

From the horse's mouth...

By 02/14/2023 04:30 AM EST

Nancy Pelosi arrived in Taiwan like a juggernaut. She defied threats from the Chinese regime in order to visit the island and ignored American generals who saw the trip as a reckless provocation. Ecstatic crowds greeted her at the airport and her hotel. Nothing, it seemed, could slow her down.

And then she met Morris Chang.

Chang, the 91-year-old founder of the chipmaking goliath TSMC, used a luncheon at Taiwan’s presidential palace to deliver a biting soliloquy to Pelosi and other visiting American lawmakers about the new industrial policy emerging in the United States. In comments that have not previously been reported in detail, Chang took aim at the CHIPS and Science Act and its $52 billion package of subsidies for semiconductor manufacturing.

Pelosi told me in a recent interview that Chang, an engineer trained at MIT and Stanford, began with a light remark.

“Fifty billion dollars – well, that’s a good start,” Chang said, according to her recollection.

Four people present for the meeting, including Pelosi, said it quickly became evident that Chang was not in a kidding mood.

Pelosi arrives in Taiwan

With Taiwan’s president, Tsai Ing-wen, looking on, the billionaire entrepreneur pressed Pelosi with sobering questions about the CHIPS law — and whether the policy represented a genuine commitment to supporting advanced industry or an impulsive attempt by the United States to seize a piece of a lucrative global market.

Chang said he was pleased that his company could benefit from the subsidies; TSMC already had a major development project underway in Arizona. But did the United States really think it could buy itself a powerhouse chipmaking industry, just like that?

That very question now hangs over the Biden administration as it prepares to implement the semiconductor spending in the CHIPS and Science Act. The next phase is due to begin this month with the unveiling by the Commerce Department of a detailed process for awarding subsidies. The law already looks like a useful political trophy for Biden, claiming a prominent spot in his State of the Union Address.

The law is an emblem, in Biden’s telling, of his commitment to creating the jobs of the future and armoring America’s economy against the disruptions that an increasingly militant China could inflict, potentially by attacking Taiwan. Pouring subsidies into chip fabrication would “make sure the supply chain for America begins in America,” Biden told Congress.

That is far from a sure bet. As Chang told Pelosi, there is a long distance between the cutting of government checks and the creation of a self-sustaining chips industry in the United States.

His candid concerns represent a rough guide to the challenges Biden’s semiconductor policy will have to address if it is to succeed, long after the immediate political fanfare has abated — and well past the point that its generous subsidies for big business have run out.

Over lunch, Chang warned that it was terribly naïve of the United States to think that it could rapidly spend its way into one of the most complex electronics-manufacturing markets in the world. The task of making semiconductor chips was almost impossibly complicated, he said, demanding Herculean labors merely to obtain the raw materials involved and requiring microscopic precision in the construction of fabrication plants and then in the assembly of the chips themselves.

Was the United States really up to that job?

The industry evolves at incredible speed, Chang continued. Even if the United States managed to build some high-quality factories with the spending Pelosi championed, it would have to keep investing more and more to keep those facilities up to date. Otherwise, he said, Americans would in short order find themselves with tens of billions of dollars’ worth of outdated hardware. A once-in-a-generation infusion of cash would not be enough.

Was America really prepared to keep up?

If the United States wanted a semiconductor industry it could rely on, Chang said, then it should keep investing in the security of Taiwan. After all, his company had long ago perfected what Americans were now trying to devise on their own.

As course upon course of small plates came and went, Chang’s discourse ran on so long that his wife, Sophie, cut in at one point with a terse interjection; Chang told the group she thought he was talking too much. Tsai, observing the whole exchange, noted to Pelosi and the other Americans that Chang had a reputation for always speaking his mind.

Several people described Chang’s remarks on condition of anonymity in order to discuss a sensitive private meeting. Indeed, the only person who agreed to speak with me about it on the record was Pelosi. She was also the only one who sounded untroubled by Chang’s skepticism about the United States as a home for the semiconductor trade.

“He knows America quite well,” she said, “and the questions he asked I saw almost as an opportunity to respond, even if some of it was challenging.”

Unlike other people I spoke to, Pelosi said she was not put off by the severity of Chang’s language. Lauding Chang as an “iconic figure,” she told me several times: “I was in such awe of him.”

But Pelosi said she had also delivered a firm message of her own: “That we knew what we were doing, that we were determined to succeed with it – that it was a good start.”

Other Taiwanese executives present voiced hesitation, Pelosi acknowledged, with some questioning whether American environmental and labor laws were consistent with the goal of nurturing a sophisticated industry. In our conversation, she rejected the idea that there might be tensions between her political party’s grand economic and social aspirations, and the narrower aims of the CHIPS law.

Chang, naturally, is not a disinterested observer of the American semiconductor effort. His company is a singular global power; its overwhelming importance in the high-tech supply chain has become a vital strategic asset for Taiwan as it gathers allies in an age of deepening conflict with the Chinese Communist Party. If China blockaded or invaded the island, the impact on TSMC’s operations alone would convulse the international economy. That is a strong incentive for wealthy democracies to defend Taiwan with more than blandishments about self-determination.

Chang has questioned in other settings whether the United States is a suitable environment for semiconductor manufacturing, pointing to gaps in the workforce and defects in the business culture. On a podcast hosted by the Brookings Institution last year, Chang lamented what he called a lack of “manufacturing talents” in the United States, owing to generations of ambitious Americans flocking to finance and internet companies instead. (“I don’t really think it’s a bad thing for the United States, actually,” he said, “but it’s a bad thing for trying to do semiconductor manufacturing in the U.S.”)

He repeated a version of that critique over lunch in August, prompting one member of Pelosi’s delegation, Rep. Raja Krishnamoorthi, to speak up and urge Chang to visit Krishnamoorthi’s home state of Illinois to get a better sense of the American workforce. Chang did not indicate he was tempted by the invitation.

When I asked several Biden administration officials about Chang’s criticism, the message I got back was a confident-sounding “stay tuned.” The next stage of CHIPS implementation, they said, would reveal in more detail how the law would be used to unlock a torrent of private-sector investment and make American semiconductor fabrication a sturdy, long-range enterprise. They did not reject Chang’s concerns about the current U.S. workforce, but pointed to American tech hubs like Silicon Valley and North Carolina’s Research Triangle as evidence that we do know how to build dynamic, fully staffed tech hubs in this country. Now, they said, we need to build more of them.

See link for rest of article.

Taiwan’s Tech King to Nancy Pelosi: U.S. Is in Over Its Head

“Fifty billion dollars – well, that’s a good start,” quipped the 91-year-old Morris Chang, warning that Washington’s new bipartisan industrial policy may not add up.By 02/14/2023 04:30 AM EST

Nancy Pelosi arrived in Taiwan like a juggernaut. She defied threats from the Chinese regime in order to visit the island and ignored American generals who saw the trip as a reckless provocation. Ecstatic crowds greeted her at the airport and her hotel. Nothing, it seemed, could slow her down.

And then she met Morris Chang.

Chang, the 91-year-old founder of the chipmaking goliath TSMC, used a luncheon at Taiwan’s presidential palace to deliver a biting soliloquy to Pelosi and other visiting American lawmakers about the new industrial policy emerging in the United States. In comments that have not previously been reported in detail, Chang took aim at the CHIPS and Science Act and its $52 billion package of subsidies for semiconductor manufacturing.

Pelosi told me in a recent interview that Chang, an engineer trained at MIT and Stanford, began with a light remark.

“Fifty billion dollars – well, that’s a good start,” Chang said, according to her recollection.

Four people present for the meeting, including Pelosi, said it quickly became evident that Chang was not in a kidding mood.

Pelosi arrives in Taiwan

With Taiwan’s president, Tsai Ing-wen, looking on, the billionaire entrepreneur pressed Pelosi with sobering questions about the CHIPS law — and whether the policy represented a genuine commitment to supporting advanced industry or an impulsive attempt by the United States to seize a piece of a lucrative global market.

Chang said he was pleased that his company could benefit from the subsidies; TSMC already had a major development project underway in Arizona. But did the United States really think it could buy itself a powerhouse chipmaking industry, just like that?

That very question now hangs over the Biden administration as it prepares to implement the semiconductor spending in the CHIPS and Science Act. The next phase is due to begin this month with the unveiling by the Commerce Department of a detailed process for awarding subsidies. The law already looks like a useful political trophy for Biden, claiming a prominent spot in his State of the Union Address.

The law is an emblem, in Biden’s telling, of his commitment to creating the jobs of the future and armoring America’s economy against the disruptions that an increasingly militant China could inflict, potentially by attacking Taiwan. Pouring subsidies into chip fabrication would “make sure the supply chain for America begins in America,” Biden told Congress.

That is far from a sure bet. As Chang told Pelosi, there is a long distance between the cutting of government checks and the creation of a self-sustaining chips industry in the United States.

His candid concerns represent a rough guide to the challenges Biden’s semiconductor policy will have to address if it is to succeed, long after the immediate political fanfare has abated — and well past the point that its generous subsidies for big business have run out.

Over lunch, Chang warned that it was terribly naïve of the United States to think that it could rapidly spend its way into one of the most complex electronics-manufacturing markets in the world. The task of making semiconductor chips was almost impossibly complicated, he said, demanding Herculean labors merely to obtain the raw materials involved and requiring microscopic precision in the construction of fabrication plants and then in the assembly of the chips themselves.

Was the United States really up to that job?

The industry evolves at incredible speed, Chang continued. Even if the United States managed to build some high-quality factories with the spending Pelosi championed, it would have to keep investing more and more to keep those facilities up to date. Otherwise, he said, Americans would in short order find themselves with tens of billions of dollars’ worth of outdated hardware. A once-in-a-generation infusion of cash would not be enough.

Was America really prepared to keep up?

If the United States wanted a semiconductor industry it could rely on, Chang said, then it should keep investing in the security of Taiwan. After all, his company had long ago perfected what Americans were now trying to devise on their own.

As course upon course of small plates came and went, Chang’s discourse ran on so long that his wife, Sophie, cut in at one point with a terse interjection; Chang told the group she thought he was talking too much. Tsai, observing the whole exchange, noted to Pelosi and the other Americans that Chang had a reputation for always speaking his mind.

Several people described Chang’s remarks on condition of anonymity in order to discuss a sensitive private meeting. Indeed, the only person who agreed to speak with me about it on the record was Pelosi. She was also the only one who sounded untroubled by Chang’s skepticism about the United States as a home for the semiconductor trade.

“He knows America quite well,” she said, “and the questions he asked I saw almost as an opportunity to respond, even if some of it was challenging.”

Unlike other people I spoke to, Pelosi said she was not put off by the severity of Chang’s language. Lauding Chang as an “iconic figure,” she told me several times: “I was in such awe of him.”

But Pelosi said she had also delivered a firm message of her own: “That we knew what we were doing, that we were determined to succeed with it – that it was a good start.”

Other Taiwanese executives present voiced hesitation, Pelosi acknowledged, with some questioning whether American environmental and labor laws were consistent with the goal of nurturing a sophisticated industry. In our conversation, she rejected the idea that there might be tensions between her political party’s grand economic and social aspirations, and the narrower aims of the CHIPS law.

Chang, naturally, is not a disinterested observer of the American semiconductor effort. His company is a singular global power; its overwhelming importance in the high-tech supply chain has become a vital strategic asset for Taiwan as it gathers allies in an age of deepening conflict with the Chinese Communist Party. If China blockaded or invaded the island, the impact on TSMC’s operations alone would convulse the international economy. That is a strong incentive for wealthy democracies to defend Taiwan with more than blandishments about self-determination.

Chang has questioned in other settings whether the United States is a suitable environment for semiconductor manufacturing, pointing to gaps in the workforce and defects in the business culture. On a podcast hosted by the Brookings Institution last year, Chang lamented what he called a lack of “manufacturing talents” in the United States, owing to generations of ambitious Americans flocking to finance and internet companies instead. (“I don’t really think it’s a bad thing for the United States, actually,” he said, “but it’s a bad thing for trying to do semiconductor manufacturing in the U.S.”)

He repeated a version of that critique over lunch in August, prompting one member of Pelosi’s delegation, Rep. Raja Krishnamoorthi, to speak up and urge Chang to visit Krishnamoorthi’s home state of Illinois to get a better sense of the American workforce. Chang did not indicate he was tempted by the invitation.

When I asked several Biden administration officials about Chang’s criticism, the message I got back was a confident-sounding “stay tuned.” The next stage of CHIPS implementation, they said, would reveal in more detail how the law would be used to unlock a torrent of private-sector investment and make American semiconductor fabrication a sturdy, long-range enterprise. They did not reject Chang’s concerns about the current U.S. workforce, but pointed to American tech hubs like Silicon Valley and North Carolina’s Research Triangle as evidence that we do know how to build dynamic, fully staffed tech hubs in this country. Now, they said, we need to build more of them.

See link for rest of article.

I don't think is a big deal for ASML, probably is just generic data. They could have bigger problems if the Chinese goverment decide not to enforce the extensive ASML EUV patent portfolio in China, which they use to gatekeep every other company out of the EUV market given the fact that ASML is not allowed to sell their EUV tools in China. They even stated something like that in their reports.

ASML can't count on the idea that China will take X amount of time to develop their own EUVL tools also given the fact that they had almost two decades of experience developing EUV related technologies and breakthroughs, believe or not, can happen sooner than most people expect when there is economic pressure.

ASML best weapon to keep their monopolistic position is to sell were the competition, present and future, exist. They get to outcompete everyone, they get to make friends, process are designed exclusive for their tools and the get to enforce their extensive IP portfolio in a more efficient way.

You actually believe ASML's claim that Chinese have stolen their trade secret?I call that BS

Bro there is something fishy about that report, maybe an admission that SSA800 DUVL will be officially introduces this year and a possible working working EUVL in 2024?

According to that article ASML also said this:

“We promptly initiated a comprehensive internal review. Based upon our initial findings we do not believe that the misappropriation is material to our business.”

They are setting up narratives for the upcoming SMEE DUVL. When SMEE goes public with their machine western media is going to refer back to this report and claim that it was made from this data.

Taiwan is a very hot place. It is not climatically suitable for high tech. If China has sufficient investment towards domestic chip industry, it is expected Chinese chip industry can match Taiwanese chip industry.

Interesting. Another domestic etching tool manufacturer.

We think the same bro, SMEE DUVL launch is imminent and ASML is preparing an excuse BUT they should be happy, it gave them a perfect alibi not to join any sanction.According to that article ASML also said this:

“We promptly initiated a comprehensive internal review. Based upon our initial findings we do not believe that the misappropriation is material to our business.”

They are setting up narratives for the upcoming SMEE DUVL. When SMEE goes public with their machine western media is going to refer back to this report and claim that it was made from this data.

Behind every Chinese advancement there's a white person that got his idea or data stolen.We think the same bro, SMEE DUVL launch is imminent and ASML is preparing an excuse BUT they should be happy, it gave them a perfect alibi not to join any sanction.

/s

So true bro BUT Huawei didn't get the message and look what happen to them...lolBehind every Chinese advancement there's a white person that got his idea or data stolen.

/s

Bro sorry for the late reply, wife ordered me to buy some groceries and it's unwise not to follow being a bonafide member of WAR (wife always right).So SMEE does not appear to be working on EUV equipment yet. Huawei on the other hand has a patent released for an EUV machine. SMEE believes they will have both their DUV dry and DUV immersion ready by the end of this year. Since they were working on both in parallel according to Havok. Though all these timelines are hard to say. People mostly think Huawei won't have that EUV ready until 2025, but no one really knows for sure.

DUVL is done and dusted, it's a collective effort done under the 13th 5 year plan from 2016 to 2020, it is also part of the 02 project. What is needed is to scale up its production and let the end user familiarized with it. SMEE is an integrator and from the ground up major enterprises was form from different scientific academe and state institution to produce those critical components like HIT (Harbin Institute of Technology) DUVL planar grating inferometer.

While on the subject of EUVL, here are their contribution

Interpretation of the dilemma of domestic lithography machine (9): Harbin Institute of Technology's EUV lithography machine light source

2023-02-16 22:14 HKTMany friends asked how the light source of the extreme ultraviolet EUV lithography machine developed by Harbin Institute of Technology is progressing ?

Before talking about this matter, please ask friends to make a simple poll. What do you think is the EUV light source power of Harbin Institute of Technology ?

Three main principles of EUV light source

Before talking about the EUV light source of Harbin Institute of Technology, let's briefly understand the history of the three main EUV light sources:The first generation: Discharged Produced Plasma (DPP)

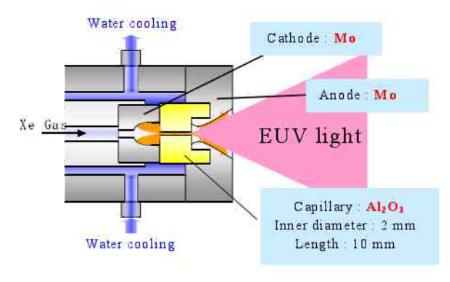

In DPP, the target is coated between the anode and the cathode, and the two electrodes generate a strong discharge under high voltage to make the target generate plasma. Due to the Z-pinch effect, when the Lorentz force contracts the plasma, the plasma is heated, producing EUV light (Figure 1) .

As early as 2003, Xtreme used Xe gas to discharge at a frequency of 1 kHz , and developed the XTS 13-35 DPP extreme ultraviolet light source prototype, which obtained 35 W extreme ultraviolet radiation power within a 2π solid angle. This is the company's first commercial prototype.

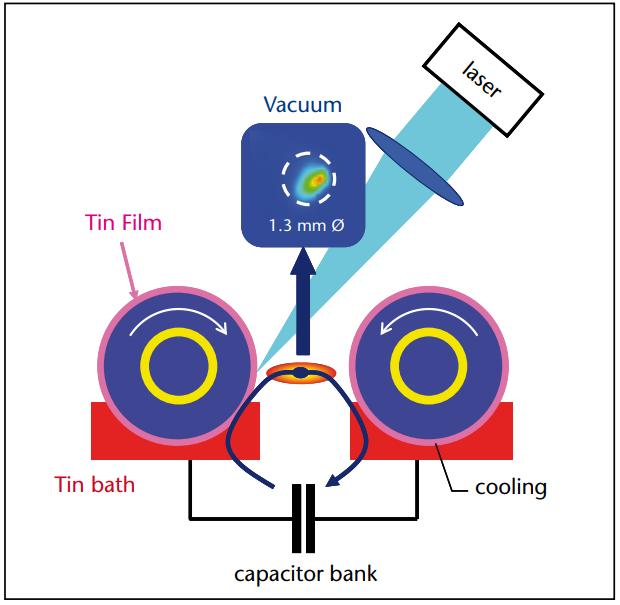

The second generation: Laser-assisted Discharge Plasma (Laser-assisted Discharge Plasma, LDP)

LDP combines LPP and DPP, first irradiates the target with a pulsed laser to refine the target, and then uses DPP technology to discharge the target to generate EUV light (Figure 2) .

In 2004, the Philips company in the Netherlands successfully developed the Nova Tin light source, which uses Sn as the working medium and can achieve 200 W of 13.5 nm extreme ultraviolet light output. Thereafter, the light sources continue to improve the company, in 2010, to increase the output power within the solid angle 2π 420 W, IF W is the output power 34 is .

In 2006, ASML's laser-assisted plasma light source installed an alpha prototype, but the power at the IF was too low to meet the requirements of industrialization.

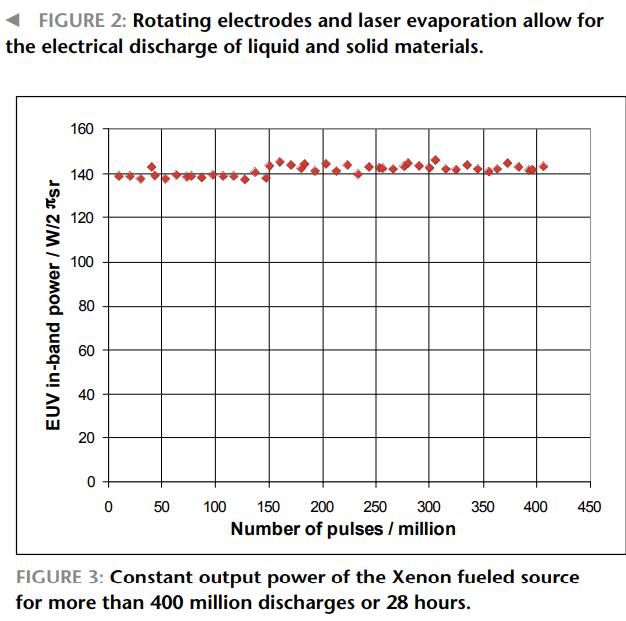

It is worth mentioning that although the power of the EUV light source of LDP technology does not meet the requirements of mass production, its stability is already very high, and it can achieve stable light emission of 400 million discharges in 28 hours (Figure 3) .

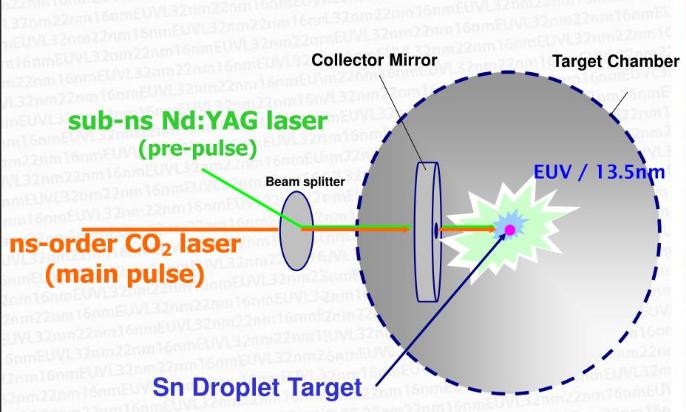

The third generation: Laser Produced Plasma (LPP)

The LPP technology uses a high-intensity pulsed laser as the driving energy to irradiate the jet Sn droplets, so that the target material generates high-temperature plasma and radiates EUV light. (Figure 4)

As we all know, the current commercial ASML high-end EUV lithography machine uses LPP light source . We have introduced many times before, it is based on 20-40kW MOPA carbon dioxide laser to achieve high EUV power. I won't go into details here, and those who are interested can read the previous article.

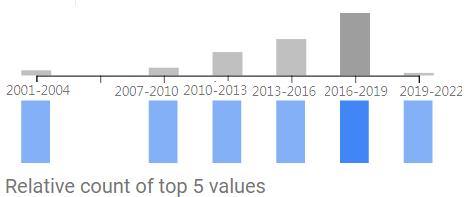

Situation of EUV-related patents of Harbin Institute of Technology from 2000 to 2020

Let's first look at the EUV light source patent data of Harbin Institute of Technology in the past 20 years, which has 147 records. Figure 51 shows the time distribution of EUV patents issued by Harbin Institute of Technology in the past 20 years.

We can see two obvious characteristics:

1. During the period 2007-2019, the number of its patents has increased substantially every year;

2. After 2019, it suddenly drops to 0. can be seen,

As we all know, Harbin Institute of Technology participated in the National Science and Technology Major Project 02 Special Project-Discharge Plasma Extreme Ultraviolet Light Source Technology Research, which was in 2009-2015. Therefore, we can roughly understand the results during the implementation of the 02 special sub-projects of these patents; perhaps after the first phase of the 02 special acceptance, the research and development work of EUV light sources tends to stagnate.

- Status

- Not open for further replies.