3. The entrepreneurial team of Xi'an Jiaotong University realized large-scale mass production of single crystal diamond substrate growth

Recently, the "Demonde Semiconductor" entrepreneurial team led by the team of Professor Wang Hongxing of Xi'an Jiaotong University has made significant progress and breakthroughs in the industrialization of single crystal diamond substrate technology. The products are mainly aimed at the fourth-generation semiconductor materials, devices and 5G communication industries. They are of great significance for breaking the foreign technology blockade, improving the level of my country's semiconductor material and device industry, and promoting the generational change of the new generation of semiconductor technology.

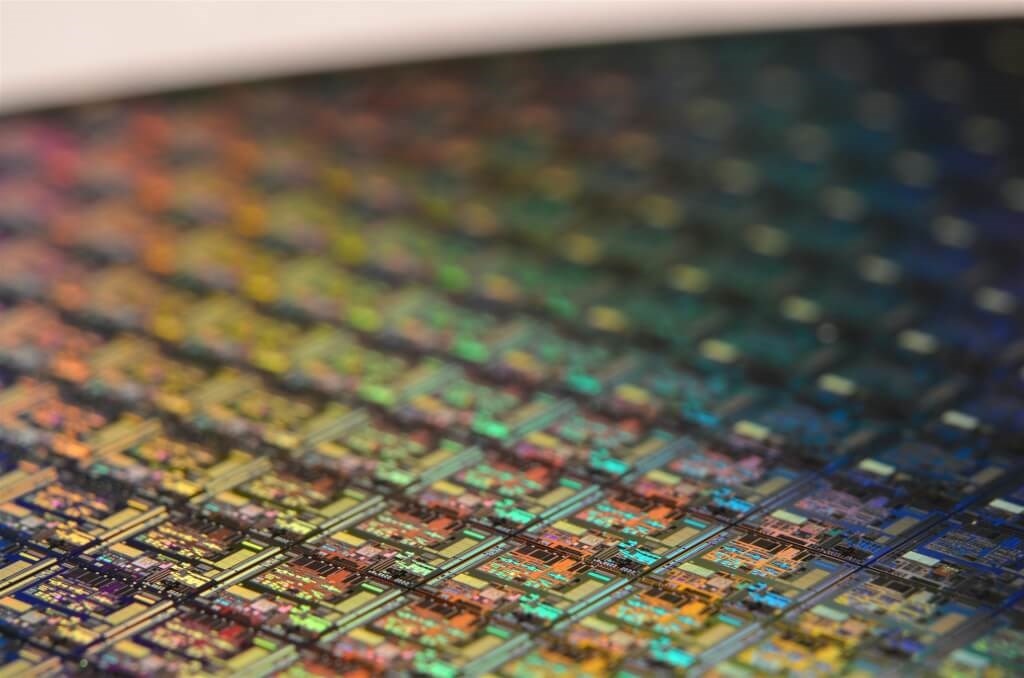

In the principle of semiconductor preparation, the substrate is a wafer made of semiconductor single crystal material. Different substrate materials can produce semiconductor chips including single crystal diamond. And single-crystal diamond is called the "ultimate semiconductor", which is the same as silicon, and its performance completely surpasses the existing semiconductors, which can overcome the bottleneck of "insufficient breakdown field strength" and "self-heating effect" of SiC and GaN. Single crystal diamond has unique advantages in electronic devices with ultra-high voltage, ultra-high current, ultra-high power, high efficiency, radiation resistance and ultra-high frequency operation without cooling.

From the perspective of the global industrial chain, some key materials, core processes, and production equipment involved in single crystal diamond substrate technology have been monopolized by Europe and the United States and other countries for a long time, threatening the security of my country's semiconductor industry and related industrial systems to a certain extent.

In order to break the constraints of the industry, as a domestic expert who has been engaged in the research of single crystal diamond wide bandgap semiconductor materials and devices for a long time, Wang Hongxing led the team to independently develop a series of single crystal diamond MPCVD deposition equipment with independent intellectual property rights after long-term scientific research. Equivalent crystal orientation growth technology of seed crystal, substrate/epitaxial growth technology, cloning technology (ion implantation, electrochemical etching, splicing and lateral epitaxy), etc., and have fully completed the principle innovation, laboratory test research and pilot test Experiments can provide large-area high-quality single-crystal diamond substrates of 1-2 inches in batches, thereby effectively ensuring the demand for high-quality, large-size electronic-grade single-crystal diamond in domestic power electronic devices, thermal conductivity, radar detection and other fields. Meet the needs of high-quality seeds for scientific research in colleges and universities.

It is especially worth mentioning that, in order to promote the rapid transformation of this technology into productivity, with the support of Xi'an Jiaotong University, the Wang Hongxing project team settled in the general window of Qinchuangyuan's innovation drive platform, and established Xi'an De Mengte Semiconductor Technology. Co., Ltd. (referred to as "Demonde Semiconductor"), the school invested all 21 core patents involved in the project, including MPCVD equipment, diamond materials, device epitaxy, etc., into the company, and connected various industrial research resources through the Qin Chuangyuan platform. Make every effort to promote its industrialization.

In addition, the investment from Shaanxi prefecture-level industrial venture capital funds also provided an important acceleration for Demond Semiconductor to accelerate the realization of scientific research results. In 2021, Hanzhong Green Recycling Fund, a subsidiary of Shaanxi Venture Capital, will invest 15 million yuan in Demotech Semiconductor. With the help of this investment capital, the project team has set up the R&D and production base in Hanzhong High-tech Zone, built a pilot production line locally, and completed the installation of more than 1,100 square meters of 10,000-class clean workshop and various supporting facilities. Up to now, 8 sets of MPCVD equipment have been officially put into production. Earlier this month, an order contract of more than 200,000 yuan was signed with a research institute of the Chinese Academy of Sciences. The entire project is expected to achieve an annual sales income of more than 18 million yuan.

Recently, the "Demonde Semiconductor" entrepreneurial team led by the team of Professor Wang Hongxing of Xi'an Jiaotong University has made significant progress and breakthroughs in the industrialization of single crystal diamond substrate technology. The products are mainly aimed at the fourth-generation semiconductor materials, devices and 5G communication industries. They are of great significance for breaking the foreign technology blockade, improving the level of my country's semiconductor material and device industry, and promoting the generational change of the new generation of semiconductor technology.

In the principle of semiconductor preparation, the substrate is a wafer made of semiconductor single crystal material. Different substrate materials can produce semiconductor chips including single crystal diamond. And single-crystal diamond is called the "ultimate semiconductor", which is the same as silicon, and its performance completely surpasses the existing semiconductors, which can overcome the bottleneck of "insufficient breakdown field strength" and "self-heating effect" of SiC and GaN. Single crystal diamond has unique advantages in electronic devices with ultra-high voltage, ultra-high current, ultra-high power, high efficiency, radiation resistance and ultra-high frequency operation without cooling.

From the perspective of the global industrial chain, some key materials, core processes, and production equipment involved in single crystal diamond substrate technology have been monopolized by Europe and the United States and other countries for a long time, threatening the security of my country's semiconductor industry and related industrial systems to a certain extent.

In order to break the constraints of the industry, as a domestic expert who has been engaged in the research of single crystal diamond wide bandgap semiconductor materials and devices for a long time, Wang Hongxing led the team to independently develop a series of single crystal diamond MPCVD deposition equipment with independent intellectual property rights after long-term scientific research. Equivalent crystal orientation growth technology of seed crystal, substrate/epitaxial growth technology, cloning technology (ion implantation, electrochemical etching, splicing and lateral epitaxy), etc., and have fully completed the principle innovation, laboratory test research and pilot test Experiments can provide large-area high-quality single-crystal diamond substrates of 1-2 inches in batches, thereby effectively ensuring the demand for high-quality, large-size electronic-grade single-crystal diamond in domestic power electronic devices, thermal conductivity, radar detection and other fields. Meet the needs of high-quality seeds for scientific research in colleges and universities.

It is especially worth mentioning that, in order to promote the rapid transformation of this technology into productivity, with the support of Xi'an Jiaotong University, the Wang Hongxing project team settled in the general window of Qinchuangyuan's innovation drive platform, and established Xi'an De Mengte Semiconductor Technology. Co., Ltd. (referred to as "Demonde Semiconductor"), the school invested all 21 core patents involved in the project, including MPCVD equipment, diamond materials, device epitaxy, etc., into the company, and connected various industrial research resources through the Qin Chuangyuan platform. Make every effort to promote its industrialization.

In addition, the investment from Shaanxi prefecture-level industrial venture capital funds also provided an important acceleration for Demond Semiconductor to accelerate the realization of scientific research results. In 2021, Hanzhong Green Recycling Fund, a subsidiary of Shaanxi Venture Capital, will invest 15 million yuan in Demotech Semiconductor. With the help of this investment capital, the project team has set up the R&D and production base in Hanzhong High-tech Zone, built a pilot production line locally, and completed the installation of more than 1,100 square meters of 10,000-class clean workshop and various supporting facilities. Up to now, 8 sets of MPCVD equipment have been officially put into production. Earlier this month, an order contract of more than 200,000 yuan was signed with a research institute of the Chinese Academy of Sciences. The entire project is expected to achieve an annual sales income of more than 18 million yuan.