Bona Semiconductor, a domestic equipment manufacturer for temporary bonding and temporary debonding, received tens of millions of yuan in A+ round financing

Recently, Zhejiang Bona Semiconductor Equipment Co., Ltd. (Bona Semiconductor), a manufacturer of temporary bonding and debonding equipment used in advanced packaging production, received tens of millions of RMB in A+ round financing from Xiaomiao Langcheng, Caitong Capital, and Dongfang Fuhai. The funds will be mainly used for equipment R&D iteration, new production line construction and market expansion. Dumu Capital serves as the exclusive financial advisor for the project and continues to provide support to the company.

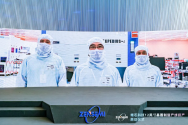

At present, Bona Semiconductor has launched a number of equipment including temporary bonding, temporary debonding equipment, and temporary debonding and cleaning all-in-one machines. The company's current mass-produced products include 12-inch fully automatic temporary debonding and cleaning integrated equipment and 12-inch fully automatic temporary bonding equipment. Based on the official launch of related wafer-level fan-out mass production lines in 2023, the number of equipment deliveries has continued to expand this year, and has obtained recognition and repeat purchase orders from many domestic 2.5D/3D, wafer-level fan-out and other advanced packaging production lines including Changdian Technology and Xinde Semiconductor.

The independent research and development rate of Bona Semiconductor's related product components has exceeded 85%. The products are more independent and controllable, and can also be developed in accordance with the specific needs of customers, and provide super cost-effective process and equipment services. The company's products are highly advanced and in a leading position in China. Compared with imported equipment, they have the advantages of high cost performance, light weight and small size.