I am asking for a response.

When I was still in R&D I had worked with KLA tools and involved in many head-to-head evaluation of their challengers. Every time, the outcome is mostly the same. KLA has better application support, more thorough sets of tools to help us deal with false defects. All new comers always focus on detection sensitivity first, as this is the first prerequisite...a ticket into the boxing ring. But detection sensitivity is conducted on test wafers/reticles. Test patterns are small so the inspection area is relatively small, and because suppliers pick and chose test wafers/reticles with no random defects, the real vs false defect phenomenon is usually not observed on the initial head-to-head phase.

But, once we put new tool into production, that's when the problem comes up. When running inspection at the required sensitivity setting (setting that could capture all defects of interest), non-KLA tools would catch so much false defects that would overwhelm the system. Inspection would abort due to not enough memory to store/capture info on the plethora of false defects. When this happens, we'd need to run at lower sensitivity just to finish an inspection run, but this would be at the risk of missing real small defect of interest.

On 'normal' runs, where manageable number of false are captured, KLA has better auto-classification software that had been refined over the years with our (end user) input. User friendly features or customized features tailor to each specific fabs are not something new challenger SME would know about nor had come up with already. I would say, this is a big reason why we don't switch out from KLA even though we want a second supplier to keep KLA honest. Basically, I had not seen tools that beat KLA enough for it to make sense for us to adopt as a second vendor or to replace KLA outright.

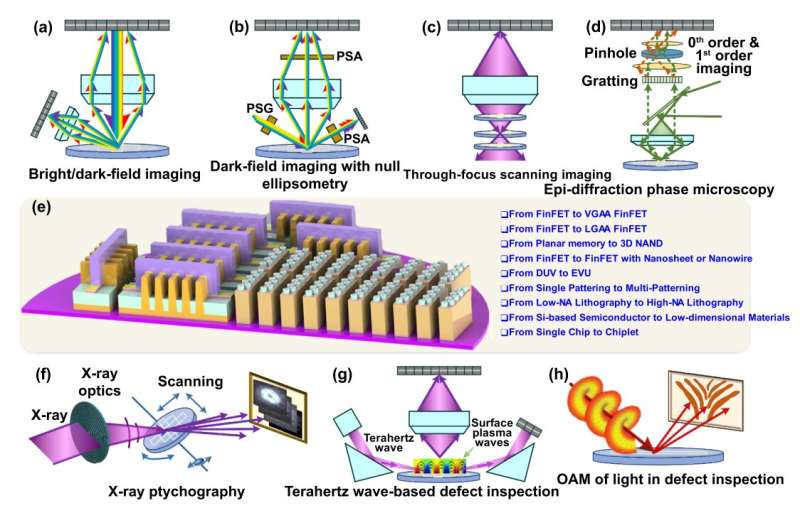

On reticle inspection, KLA's forte is their die-to-database capability. Their ability to render a reference image from GDS file is unrivaled. Despite Lasertec having actinic light source that would give them better pattern and defect resolution...and hence better signal-to-noise, Lasertec was not able to achieve same level of GDS-to-reference image rendering. At best, Lasertec EUV reticle inspection is better than KLA's DUV die-to-die inspection. But for die-to-database inspection which is much more crucial in the R&D stage, KLA still wins out. This I was able to verify from talking to some former colleagues.

And at the end of the day, most of us prefer working with KLA because of the long history of collaboration and familiarity. That is also a moat that KLA enjoys against their challengers.

There's more reasons, but I'll just end right here. Signal-to-noise performance dictating real/false defect detection dynamic is what KLA had mastered during their multiple decade of dominance. It may sound simple, but it's what keeps KLA in the dominant position in the metrology/inspection/yield enhancement arena.

You are saying they received a positive feedback loop from the big fabs and due a iterative process they become really good at detecting false positives. But, in my opinion, that doesn't mean they can't be replaced. If KLA can't sell their products in China i do think that Chinese and non Chinese companies are going to replace them and in the same iterative process that make their tools really good will make their competitors also really good and probably even faster because the Chinese companies now have KLA tools to benchmarks their own. Just my opinion.

easier said than done. you don't see people rushing to buy Jincee inspection tools to replace KLA for 14nm...7nm.

with smaller resolution, the signal-to-noise issue gets worse. From what's happening at SMIC, they are still stuck at getting domestic tools to work efficiently at 28nm. I have not heard of major domestic inspection or metrology breakthrough that would enable replacing KLA at 14nm nor 7nm. This is why SMIC 14nm & 7nm capacity had been stuck at the same pre-Oct 7th sanction level....no change for a year now. This doesn't sound like domestic tools is making headway at 14nm/7nm, does it?