Sir remember Huawei Kirin 9006C 5nm chips.people where astounded how Huawei were able to produce such chips with TSMC restriction being imposed on them, well the answer is Huawei are doing the packaging with the unfinished chip being bought en masses before the deadline. Here the same is happening with SMIC unfinished12NM and 14NM chips.

Unexpectedly, the new 5nm Kirin Kirin 9006C came out. Who is OEM for Huawei?

Due to changes in the international situation and changes in the US semiconductor market rules, Huawei's Kirin chips were forced to suspend production after September 2020.

As we all know, the Kirin chip is Huawei's self-developed chip, which has been applied to Huawei mobile phones before. After the production of Kirin chips was discontinued, the output of Huawei's mobile phones was inevitably affected, which led to a decline in mobile phone sales.

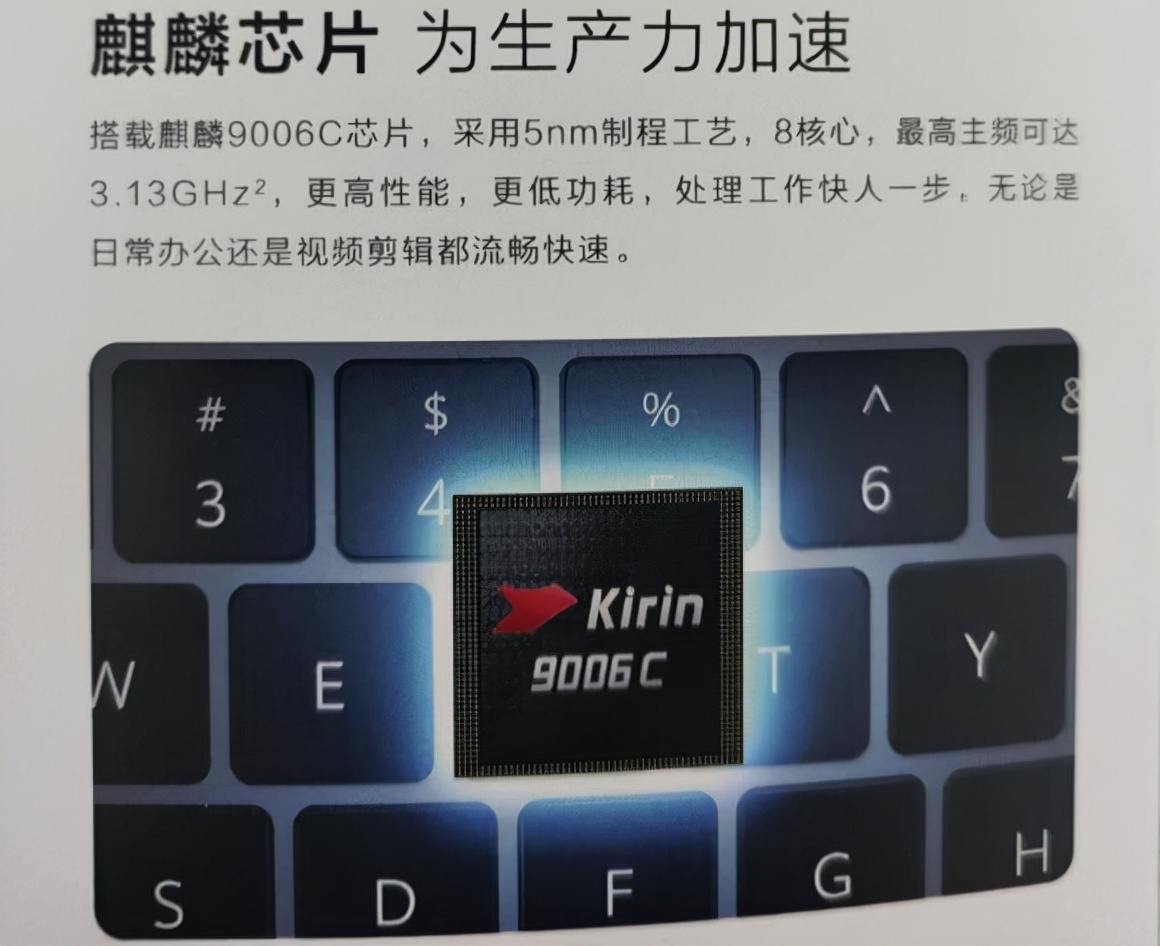

Zhongguancun Online reported on December 3 that Huawei's new MateBook still uses the Kirin chip, and it is the Kirin 9006C that has never appeared before.

It should be noted that this processor, named Kirin 9006C, uses a 5nm process. Not to mention the performance of this chip, the use of the 5nm process alone is surprising enough.

You know, looking at the world, only TSMC and Samsung can achieve mass production of 5nm process , but these two foundries are unlikely to produce advanced 5nm process chips for Huawei at this time.

So, the question is, who is it that made the Kirin chip for Huawei? There are divergent opinions on this issue on the Internet. Although there is no exact statement at present, there are also two speculations.

The first is that Kirin 9006C is a chip previously produced by TSMC ;

There is one thing to say that the appearance of the Kirin 9006C at this time is really a bit abrupt. After all, after the Huawei 9000 chip, Huawei has not launched a new Kirin chip, and there is currently no foundry that can produce 5nm chips for Huawei.

Given that Huawei's current chip inventory is still a mystery, it is not clear how many Kirin chips Huawei has, and how many Kirin chips are in stock. Therefore, the Kirin 9006C is likely to be a chip produced by TSMC and Huawei during the cooperation.

The second argument is that Kirin 9006C is transformed from Kirin 9000 ;

This argument is not a vacancy. From the perspective of parameters, the Kirin 9006C and the Kirin 9000 chip have certain similarities.

Kirin 9006C and Kirin 9000 both use 5nm process and also have a 3.13GHz Cortex-A77 super core. Although the GPU is different, the difference is not big. The GPU of Kirin 9006C is Mali-G78 MP22, while Kirin 9000 is Mali-G78 MP24. Therefore, from the perspective of parameters, the Kirin 9006C is likely to be a modified version of the Kirin 9000.

No matter how the Kirin 9006C came about, its advent is a good thing for Huawei. It can not only enhance the competitiveness of Huawei's products, but also increase Huawei's market influence.

In recent years, the strength of Huawei's Kirin chips has never disappointed consumers, and the self-developed Kirin chips have become a competitive advantage of Huawei products in the market. According to reports from Zhongguancun Online, Kirin 9006C is a product with stronger performance and lower power consumption. Huawei's new MateBook adopts this chip, which will inevitably enhance product competitiveness.

In addition, Huawei's current situation is very difficult, especially for HiSilicon Kirin chips. As mentioned in the previous article, Huawei HiSilicon has not launched new products since Kirin 9000. In addition, the inventory of products equipped with Kirin chips is decreasing. Huawei or Said that the market influence of Huawei HiSilicon Kirin chips is gradually weakening.

Although Kirin 9006C is not a chip for smart phone products, as a member of the Kirin family, its advent will inevitably usher in a large wave of attention, thereby enhancing the competitiveness of Huawei and Huawei HiSilicon in the market.

Not only that, although Huawei HiSilicon Kirin chips are no longer in production, Huawei has not given up HiSilicon, and has not disbanded the HiSilicon team. But it should be noted that if you want to maintain the normal operation of Huawei HiSilicon, you need to invest a lot of money. After Kirin 9006C enters the market, it can increase economic income to a certain extent and reduce Huawei's pressure.

Is it possible the Kirin 9000 is the 14nm with 3D stack that reach performance equal to 5nm?