Example of application of solid state microwave source on diamond semiconductor films.

There is no internal electrode in the cavity of microwave plasma chemical vapor deposition (MPCVD), which can avoid the pollution caused by electrode discharge. Its operating pressure range is relatively wide, and the generated plasma has high density, large area, high stability, and no It is in contact with the vacuum wall, thus avoiding the contamination of the film by the wall. Therefore, microwave plasma chemical vapor deposition (MPCVD) has become one of the most promising high-quality diamond film deposition methods due to its unique advantages.

In the past, people habitually used the well-known magnetron power source to apply to the MPCVD system. With the rapid development of technology, it has become a new trend to replace the magnetron solution with the solid-state RF microwave power source in the MPCVD system. trend.

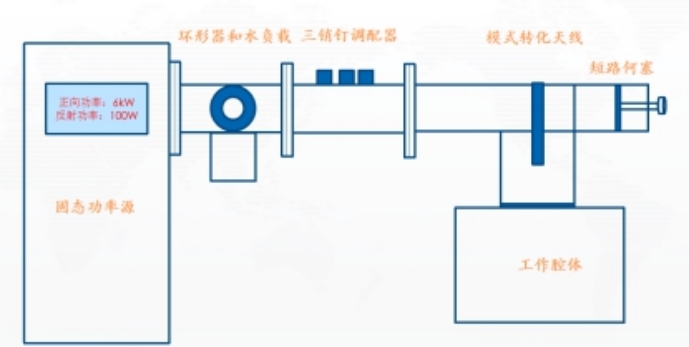

Schematic diagram of the application framework of solid-state microwave sources in MPCVD systems (taking 6kW as an example)

Application advantage analysis of solid-state microwave source in MPCVD system

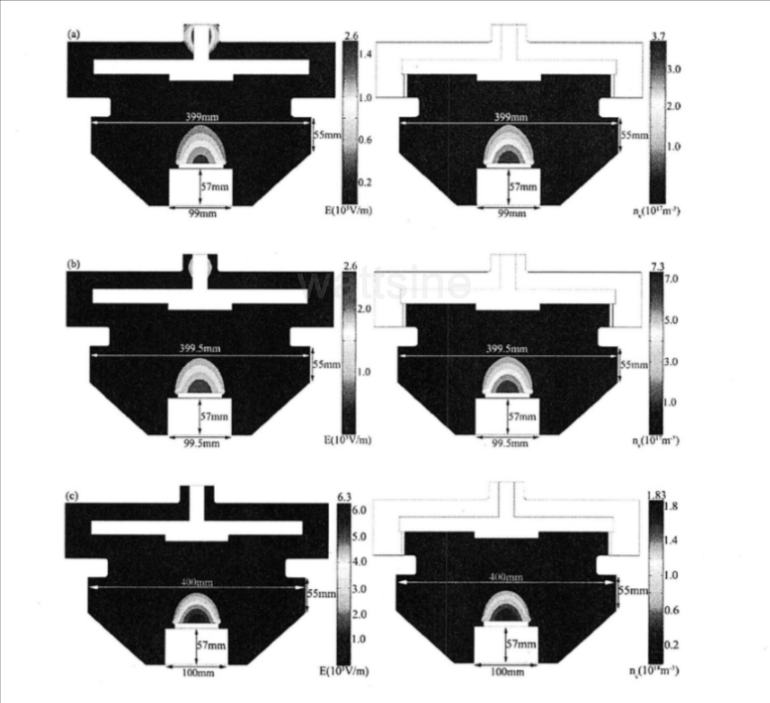

In the MPCVD device, various factors such as microwave frequency, cavity size, and sample base will lead to the electric field distribution and plasma state and distribution in the cavity. The following is the data analysis of a bachelor from Taiyuan University of Technology:

(Figure 1)

In the MPCVD device, even a frequency change of 10MHz will cause strong changes in the electric field and plasma intensity and distribution state in the cavity

Figure II)

In the MPCVD device, the size of the resonant cavity causes strong changes in the electric field and plasma intensity and distribution state in the cavity

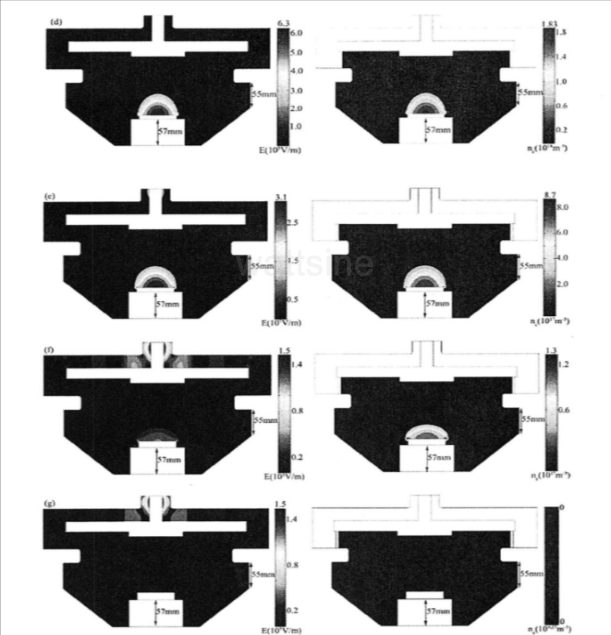

(Picture 3)

In the MPCVD device, the position of the sample base causes strong changes in the electric field and plasma intensity and distribution state in the cavity

The Wattsine solid-state power source has controllable frequency and phase. We can adjust the frequency and phase of the microwave source to compensate for the distribution and change of the electric field distribution and plasma state caused by various changes in the cavity size and sample base. .

The MPCVD device using Wattsine's solid-state power source will not change the working state of the device due to the replacement of the power source, and will not need to re-adjust and set the working parameters of the device.