Huaying Micro 12-inch automatic edge corrosion equipment was successfully delivered

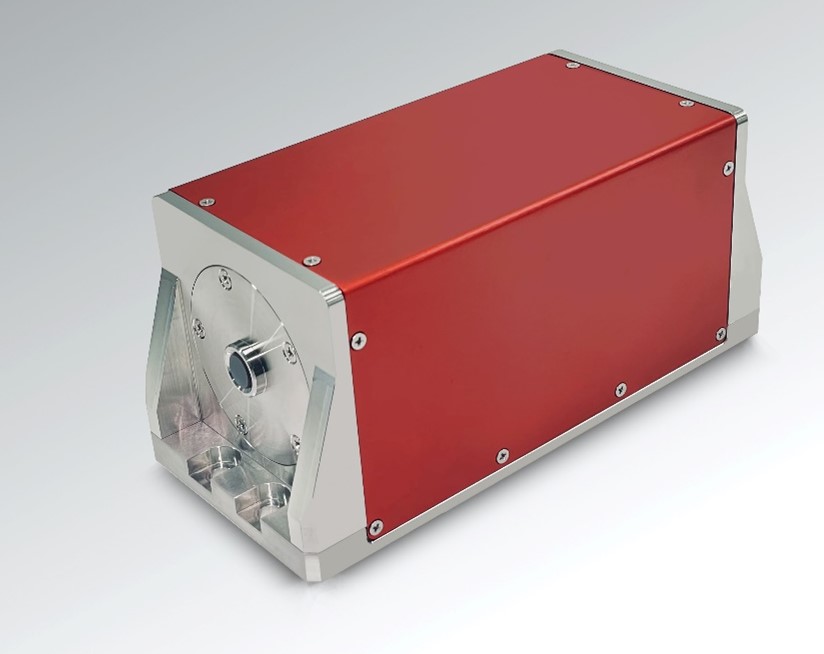

On September 18, 2022, the 12-inch automatic edge corrosion equipment produced by Wuxi Huaying Microelectronics Technology Co., Ltd. was delivered to customers on time.

The equipment can achieve precise etching of the wafer edge, with a precision control of ±0.1mm; at the same time, it saves 50% of the process time, and improves the process safety and the ESH index of the process; in addition, it greatly reduces the chemical corrosion gas. It can save 90% of ultra-pure water and more than 50% of chemical liquid, which can save the cost of ultra-pure chemicals worth millions of yuan each year for customers and enterprises, as well as the treatment cost of their production waste liquid.

Since its establishment, Huaying Micro has always adhered to the company's entrepreneurial philosophy of "technology and environmental protection coexist, innovation and green mountains and green waters coexist". All of the company's R&D designs abide by the tenet of "innovation and environmental protection" first. It is committed to solving many problems such as water resources, environmental protection, and lack of independent innovation technology that the country will face in the development of the semiconductor manufacturing industry. In the future, Huaying Micro will continue to provide the industry and customers with more environmentally friendly, green and advanced semiconductor manufacturing equipment.

Huaying Micro 6/8 inch automatic passivation equipment was successfully delivered

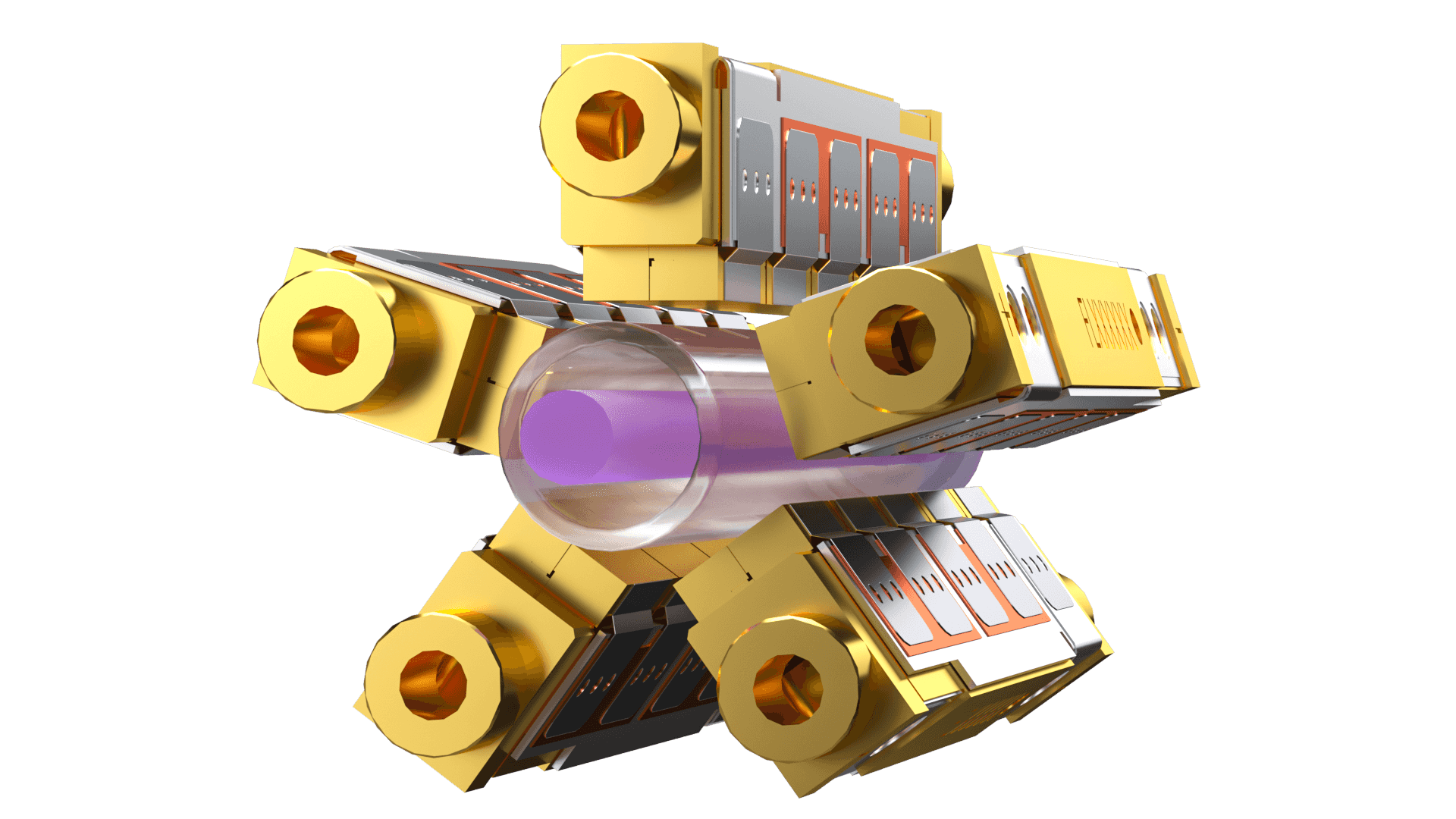

Release date: 2022/08/17On August 15, 2022, the 6/8-inch compatible fully automatic passivation equipment produced by Wuxi Huaying Microelectronics Technology Co., Ltd. was successfully delivered to customers.

This is Huaying Micro's first fully automatic multi-cavity passivation equipment. The equipment has the characteristics of good process repeatability and high film-forming efficiency, and greatly reduces the process cost, and solves many long-standing problems in the existing passivation process and equipment.

The new passivation equipment shipped by Huaying Micro is equipped with multiple chambers, which greatly improves the production efficiency. At the same time, it can realize dry in and dry out, online recovery and recycling of used chemical solvents, etc., which can save more than 50%. Process time, save more than 90% of chemicals, save a lot of production costs for enterprises, and better protect resources and protect the environment.

Huaying Micro is committed to the design and manufacture of industry-leading, green and environmentally friendly new semiconductor manufacturing and production special cleaning equipment and new processes. The coexistence of technology and environmental protection, innovation and green mountains and clear waters are the foundation of Huaying Micro's foothold in the field of semiconductor manufacturing. Huaying Micro uses its own original technology, and strives to bring the best experience to customers.

(Contributed by Xu Lu)