In June 2021, Beijing Yitang Semiconductor Technology Co., Ltd.'s

Also known as Mattson Technology

In June 2021, Beijing Yitang Semiconductor Technology Co., Ltd.'s

I think would be difficult to manufacture Rad Hardened ICs using current smaller nodes techniques. Even automakers have a lot of difficulty moving on from reliable matures nodes, let alone the military.Although wouldn't really low nanometers kinda be weak/not good against EW? Or was it EMP (although big emp bombs can only be achieved by nukes iirc, and even then I think even stuff at 90nm+ still needs to have some modifications to protect them from that?)

From your own source:You couldn't have asked such question at a better time. "Shenyang Fortune-Semi",a supplier of components for semiconductor equipment just passed IPO,and released some interesting material regarding the requirement for components for different node process.

Apparently,14nm has higher requirement for components than 28nm. Since higher grade components costs more,equipment manufactures won't use components designed for 14nm on 28nm machines because it doesn't make economic sense.

You can see the full report here if whish to

View attachment 89885

View attachment 89886

View attachment 89887

Hey from your source, if this was indeed 100% hard standards with 0 deviation allowed, it meant that they were using 200 mm wafer in 2016.You couldn't have asked such question at a better time. "Shenyang Fortune-Semi",a supplier of components for semiconductor equipment just passed IPO,and released some interesting material regarding the requirement for components for different node process.

Apparently,14nm has higher requirement for components than 28nm. Since higher grade components costs more,equipment manufactures won't use components designed for 14nm on 28nm machines because it doesn't make economic sense.

You can see the full report here if whish to

View attachment 89885

View attachment 89886

View attachment 89887

Yup China will inundate us, not with Cheap products BUT with Chip products!...lol with SMEE SSA800 DUVL and its future iteration, we can say China will commoditize the 14nm, 12nm, 10nm and 7nm chip markets, leaving 5nm and 3nm niche chips to the present 3 market leaders.

@horse bro good day!!!! Yup ! China has a plan, The Made in China strategy, the US had a counter plan straight from a thesis of Miss Curseula Von der Lying which is Ban everything. Your analysis of Trump is straight on, when he win, he will do a Nixon and proclaim that he save the world from a devastating War with China and Made America Great Again with More Chip import for our beloved Iphone....lolYeah, exactly brother, that is what I believe is the correct strategy to follow for the Chinese IC industry.

Get close to the leading edge, but do not work too hard to get to the leading edge.

The problem with the leading edge, it just takes too much money to sustain.

There is the curious point about IC today. The structure of the industry, or in Clausewitz terms, the battlefield.

1. The leading edge is the most capital intensive in exponential amounts. And much of that output is sold to China. Not sure what the point is for China to rush to the leading edge, when those companies at the leading edge have to sell it to China regardless.

2. It would be easier and faster to develop all of the mature nodes for China, the complete supply chain. It is like a horse race. There are the leaders, then there are the horses not running in front, but keeping pace waiting to make its move later in the race.

That is how this game is being played. Or this is the structure of the industry. Or this is the battlefield. Misinterpret what we see on the battlefield, and the results could be fatal. That trade war was a joke. Yet they did it.

It is very interesting. Because everyone believes they got the other side exactly where they want them. The leaders want China chasing them. China wants to be close, but not actively challenging for the lead neck to neck.

If recent history is any guide, China is pretty sure how this race will turn out. President Trump will be so mad!

Bigly!

Do you think there will be more companies surprising the world's bashers with new Chinese chip technology?@horse bro good day!!!! Yup ! China has a plan, The Made in China strategy, the US had a counter plan straight from a thesis of Miss Curseula Von der Lying which is Ban everything. Your analysis of Trump is straight on, when he win, he will do a Nixon and proclaim that he save the world from a devastating War with China and Made America Great Again with More Chip import for our beloved Iphone....lol

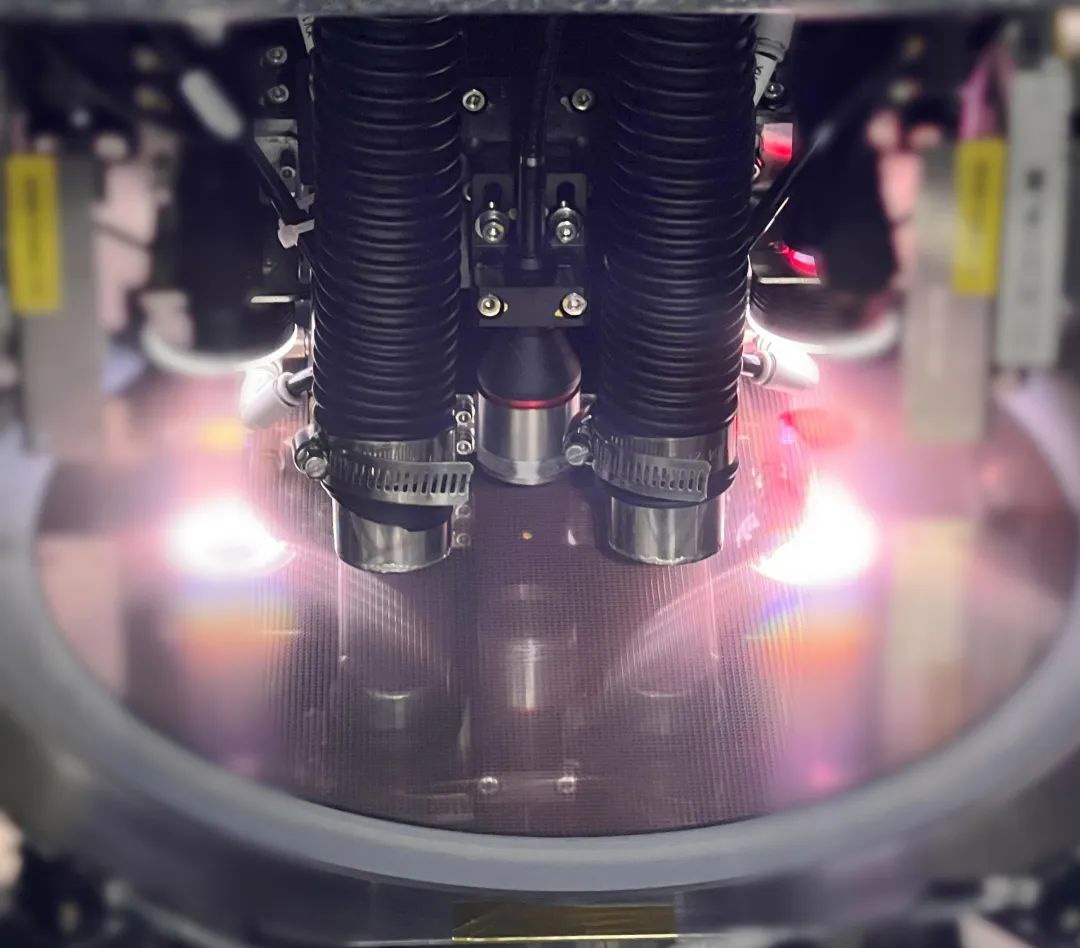

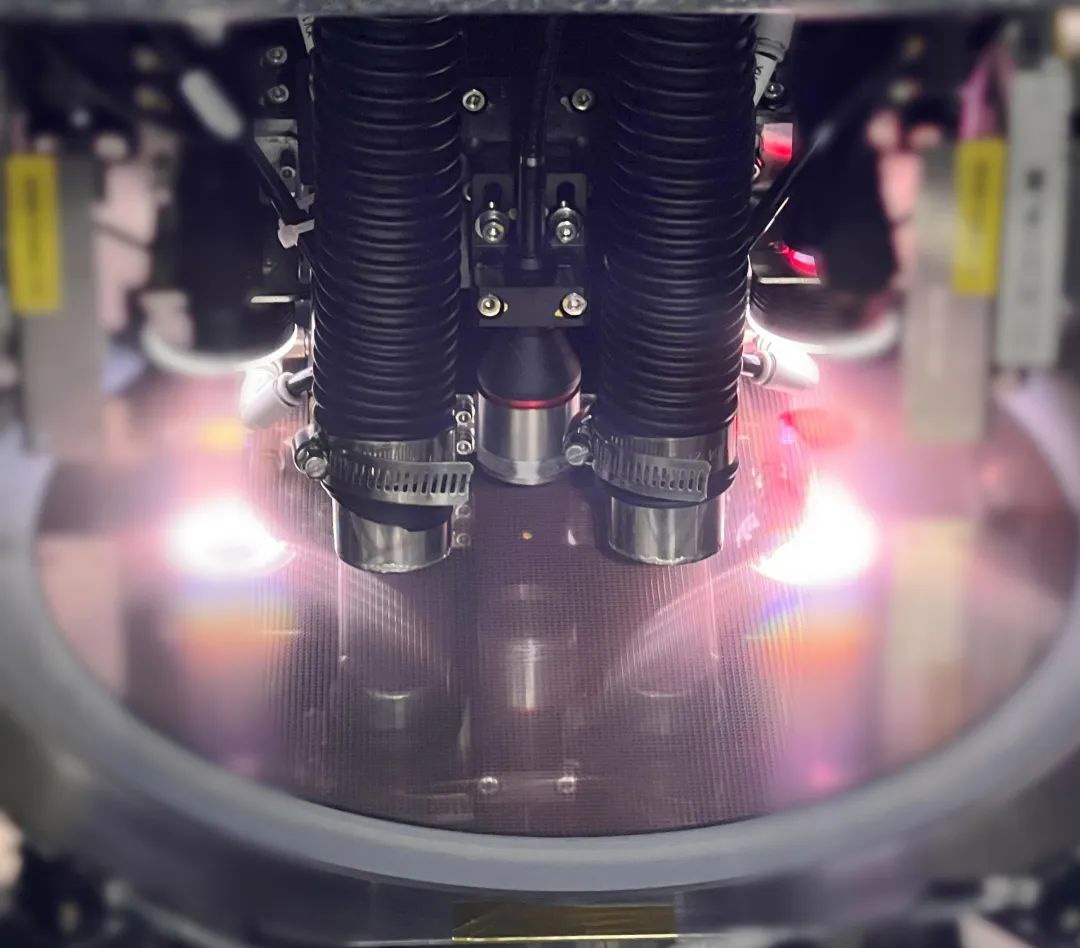

While waiting for its EUVL , China had develop other equipment needed to produce 5nm Chips and here is one of them, an obscure Chinese Company in the name of China Great Wall , has launched a fully automatic 12-inch wafer laser slotting equipment supporting ultra-thin wafer cutting process. Now for me this is a surprise, never heard the company until now and we have just scratch the surface so to speak.

Apr 6, 2022 — Minimum 5nm, China Great Wall announced the launch of fully automatic 12-inch wafer laser grooving equipment ... Fully automatic 12-inch wafer ...

Minimum 5nm, China Great Wall announced the launch of fully automatic 12-inch wafer laser grooving equipment

2022-06-02 15:57 HKT

IT House April 6 news, today, China Great Wall official micro announced that the company's Zhengzhou Rail Transit Information Technology Research Institute, based on the experience and basis of the development of semiconductor laser invisible wafer cutting equipment, has launched a new technology that supports full cutting of ultra-thin wafers. Fully automatic 12-inch wafer laser grooving equipment for the process .

According to reports, in addition to the conventional laser grooving function, the device also supports 5nm DBG process , ultra-thin wafer full cutting function below 120 microns, fab IGBT process side related processes and TAIKO ultra-thin ring cutting and other high-precision end process.

IT House learned that the Great Wall of China official stated that the modular design of the device can support lasers with different pulse widths (nanosecond, picosecond, femtosecond). The self-developed optical system can realize continuous adjustment of the width and length of the spot. With the high-precision motion control platform and other technologies, it is combined with the laser stealth cutting equipment to solve the problems of laser stealth cutting equipment on surface material, thickness, crystal orientation and resistivity. Limit, help control product breakage rate and improve chip yield.

Today, leading edge process is much more expensive than legacy process but the number of customers is small because very few companies can afford to manufacture at these nodes and the tradeoffs are not worth it.Yeah, exactly brother, that is what I believe is the correct strategy to follow for the Chinese IC industry.

Get close to the leading edge, but do not work too hard to get to the leading edge.

The problem with the leading edge, it just takes too much money to sustain.

There is the curious point about IC today. The structure of the industry, or in Clausewitz terms, the battlefield.

1. The leading edge is the most capital intensive in exponential amounts. And much of that output is sold to China. Not sure what the point is for China to rush to the leading edge, when those companies at the leading edge have to sell it to China regardless.

2. It would be easier and faster to develop all of the mature nodes for China, the complete supply chain. It is like a horse race. There are the leaders, then there are the horses not running in front, but keeping pace waiting to make its move later in the race.

That is how this game is being played. Or this is the structure of the industry. Or this is the battlefield. Misinterpret what we see on the battlefield, and the results could be fatal. That trade war was a joke. Yet they did it.

It is very interesting. Because everyone believes they got the other side exactly where they want them. The leaders want China chasing them. China wants to be close, but not actively challenging for the lead neck to neck.

If recent history is any guide, China is pretty sure how this race will turn out. President Trump will be so mad!

Bigly!