In recent years, Runxin Sensing, which has settled in Nanchang High-tech Zone in Jiangxi Province, is a MEMS wafer production line invested in by Nanchang High-tech Zone. It acts in a low-key and pragmatic manner, but has quietly grown into the main foundry with the largest annual shipments of domestic BAW filters.

According to the information, Runxin Perception was established in March 2022. The Runxin Perception MEMS Sensor Industrial Park project in Nanchang High-tech Zone with a total investment of 5 billion yuan was built in two phases. At present, it has quietly cultivated mass production skills for two years in the first phase. The core operation team of this production line originated from China Resources Microelectronics, a leading Chinese semiconductor company with nearly 20 years of experience in smart sensor manufacturing. This has allowed Runxin Perception to stand at a high starting point in the industry since its birth. China Resources Microelectronics' excellent manufacturing technology and strict quality control system have provided a solid foundation and inexhaustible power for the rapid development of Runxin Perception.

If the development of domestic BAW filters has long been trapped by the problem of "samples can be made, but mass production is uncontrollable", then the production line of Runxin Sensing is undoubtedly the breakthrough point for the first large-scale shipment of BAW products. More importantly,

the products here are not only leading in production, but also truly "not inferior to overseas" in performance.

Strong alliance, BAW team warms up

It is understood that the BAW system produced by Runxin Perception is designed by

Xinsheng Semiconductor , a cutting-edge company in the filter field. Relying on Runxin Perception's reliable MEMS manufacturing platform, the two parties have created the industry-leading D-BAW filter based on strategic cooperation, leading the "new model" of close collaboration between independent design and local manufacturing.

View attachment 155209

Supply chain sources indicate that the Runxin sensing production line has shipped more than 300 million Xinsheng D-BAW filters in the past year . The products have been in stable service in mainstream mobile phones and tablet terminal devices, and some models have also been used in many domestic and foreign high-end flagship mobile phones.

In the current domestic BAW filter shipment ranking, Xinsheng's D-BAW ranks first with a significant share advantage, and its shipment scale far exceeds that of other market followers.

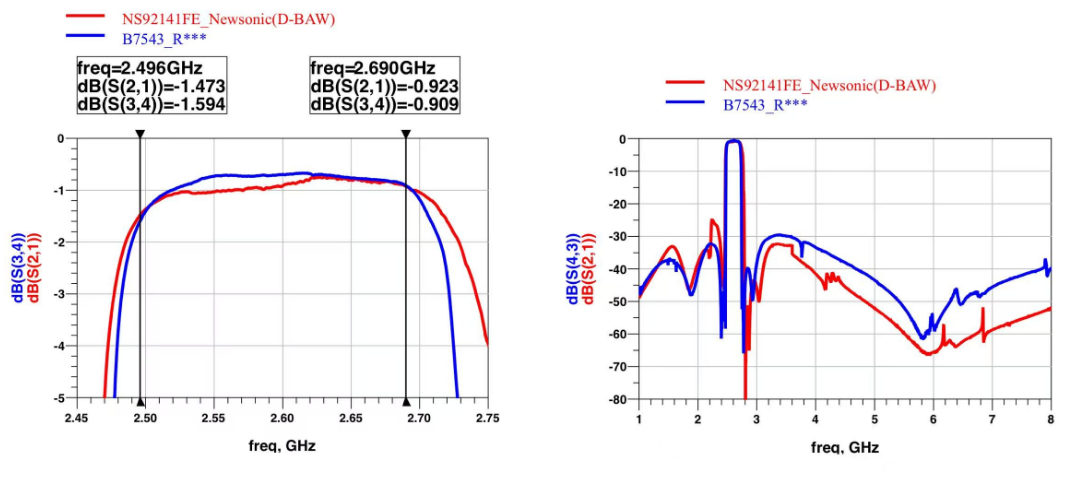

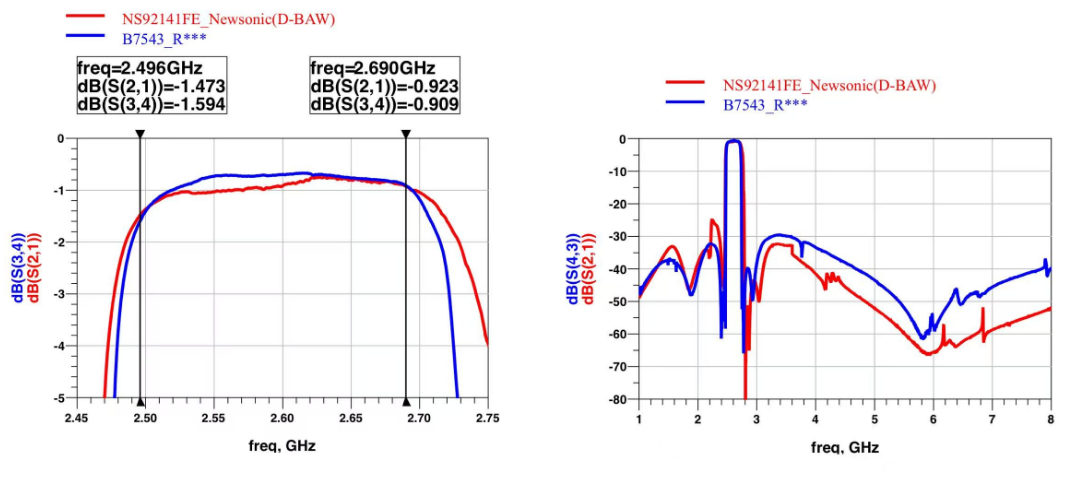

In terms of specific product performance, the D-BAW filter jointly developed by Runxin Sensing and Xinsheng has achieved comprehensive benchmarking against international advanced products. It uses Xinsheng's first SiRoof packaging solution for complete silicon cap + dry film organic bonding, which greatly enhances the durability and stability of the product. Taking the following figure as an example, it can be seen that in terms of passband insertion loss, Xinsheng D-BAW's product performance is highly close to international mainstream products. Especially at the center frequency of 2.690GHz, the insertion loss is as low as -0.923 dB, which is almost the same as the benchmark product; and in terms of out-of-band suppression, some frequency bands are even better than overseas solutions, especially in the far-away passband areas of 2GHz-3GHz and above 5GHz, reflecting better suppression capabilities.

It is worth emphasizing that these performance data are not from laboratory samples, but from mass-produced products that have undergone reliability testing at the Runxin Sensing Nanchang production line. This means that

domestic BAW filters are no longer at the "technology demonstration" stage, but have actually entered the commercial landing stage of "controllable performance, stable quality, and customer verification."