Temperature control for lithography machines.

Airsys temperature control innovation overcomes overseas technical barriers and leads the rise of domestic products.

In 2025, the localization rate of China's semiconductor equipment is expected to reach 35%-50%. In response to national policies, AIRSYS promotes the localization transformation of the semiconductor industry and injects new impetus into China's semiconductor industry with its innovative breakthroughs in wafer-level precision temperature control modules.

The core advantages of AIRSYS temperature control technology

1. High-precision temperature control module

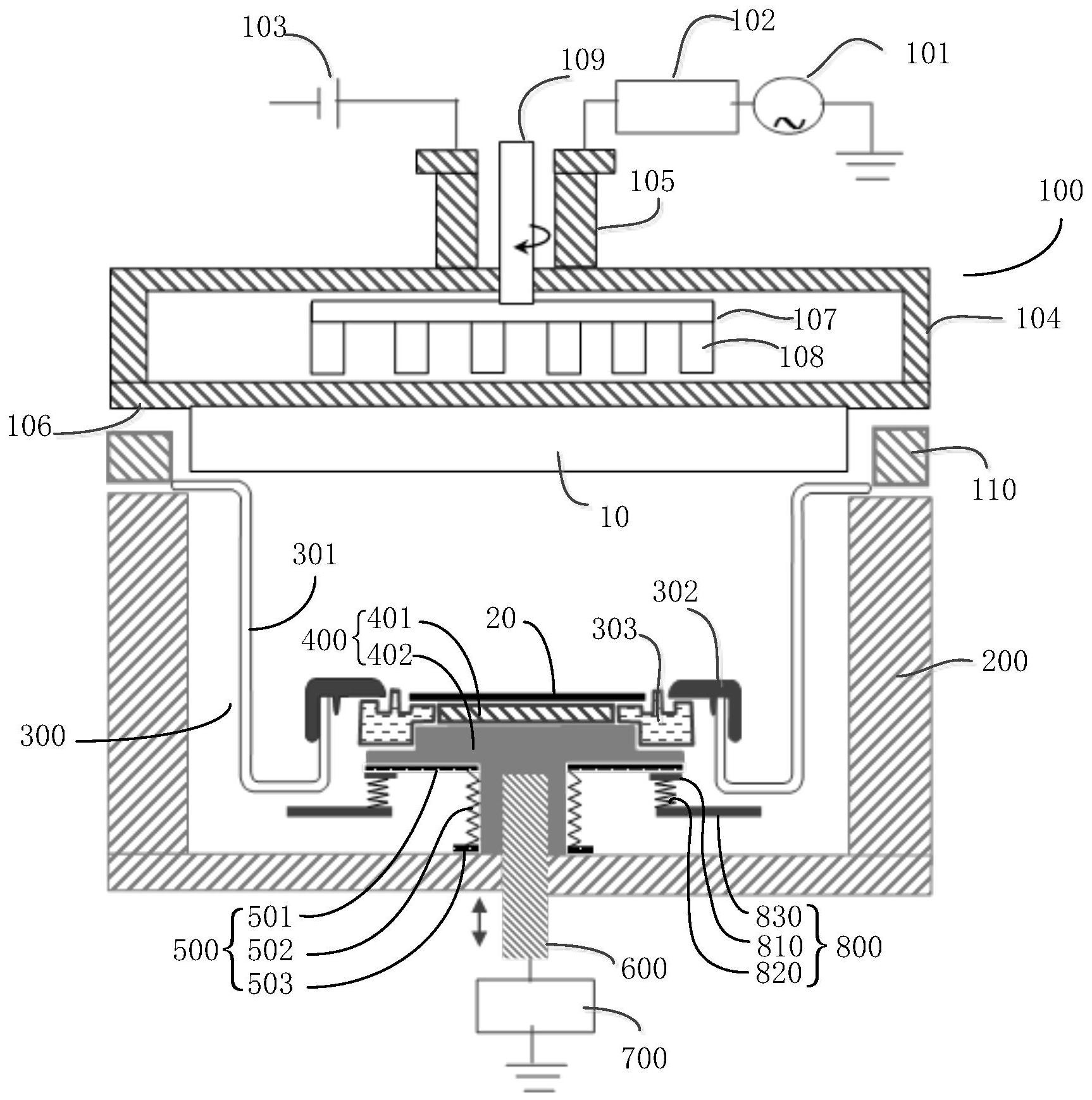

The precision temperature control module developed by AIRSYS is suitable for wafer processing and is designed for the core process of semiconductor manufacturing, covering key steps such as photoresist coating and wafer inspection. The module uses advanced sensor technology and intelligent control system to achieve high-precision temperature control of ±0.005℃, ensuring process stability and repeatability. Its unique dual-channel design enables the equipment to quickly switch temperature ranges at different process stages to meet diverse needs from low temperature to high temperature.

2. Technological breakthrough: full-chain innovation from algorithms to materials

AIRSYS has always maintained a large investment in innovation and research and development, and has continuously introduced efficient cooling/heating technologies and advanced algorithms, allowing temperature control equipment to reach international leading levels in terms of accuracy, stability and energy efficiency. At the same time, AIRSYS also provides customized solutions to tailor the most suitable temperature control system according to the process requirements of different customers. This "technology + service" dual-wheel drive model is reshaping the competitive landscape of China's temperature control equipment market.

3.

Reliability and stability

In semiconductor manufacturing, reliable equipment and stability are essential. Airsys' temperature control equipment uses special low-temperature alloy materials and modular antifreeze design. The core parts can withstand extreme environments, ensuring the reliability and durability of the equipment under high-load operation. The equipment is also equipped with different safety protection mechanisms, which can monitor the operating status in real time, quickly warn and handle faults, and ensure the continuity of the production process.

4. Market recognition of AIRSYS temperature control technology

AIRSYS's temperature control technology is highly reliable and innovative, and has been widely recognized by domestic semiconductor production lines. Not only has the product achieved significant sales in the domestic market, it has also attracted the attention of many internationally renowned companies. At the SEMICON China 2025 exhibition, AIRSYS attracted a large number of industry elites to stop and negotiate with its ±0.005℃ ultra-precision temperature control technology and AI-driven digital management platform, and won a lot of cooperation intentions. Many of the world's top 10 semiconductor companies made a special trip to visit the AIRSYS exhibition area to communicate and exchange technical advantages and service systems, which consolidated AIRSYS's core position in the industrial chain.

-------------------------

Interesting:

According to "Made in China 2025", clear requirements are put forward for the localization of semiconductor equipment:

As of 2020

Achieve a 50% localization rate for 90-32 nanometer process equipment, a 50% localization rate for key packaging and testing equipment, and a 90 nanometer lithography machine

By 2025

Achieve 30% localization rate of 20-14 nanometer process equipment and localization of immersion lithography equipment

By 2030

Realize the localization of process equipment, EUV lithography equipment, and packaging and testing equipment

In 2025, the localization rate of China's semiconductor equipment is expected to reach 35%-50%. In response to national policies, AIRSYS promotes the localization transformation of the semiconductor industry and injects new impetus into China's semiconductor industry with its innovative breakthroughs in wafer-level precision temperature control modules.