Xin'en's "wafer carrier and semiconductor inspection system" patent is authorized ..

Tianyancha shows that Xin'en (Qingdao) Integrated Circuit Co., Ltd. recently obtained a patent called "Wafer Carrier and Semiconductor Inspection System", and the authorization announcement date is June 18, 2024. The patent solves the problem of abnormal measurement data caused by charge loss at the edge of the wafer to be inspected..

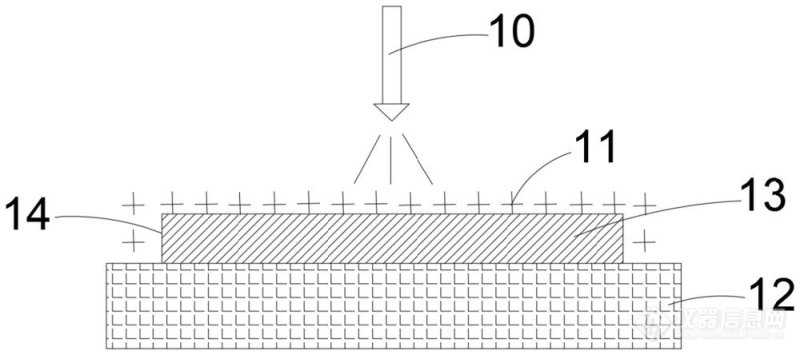

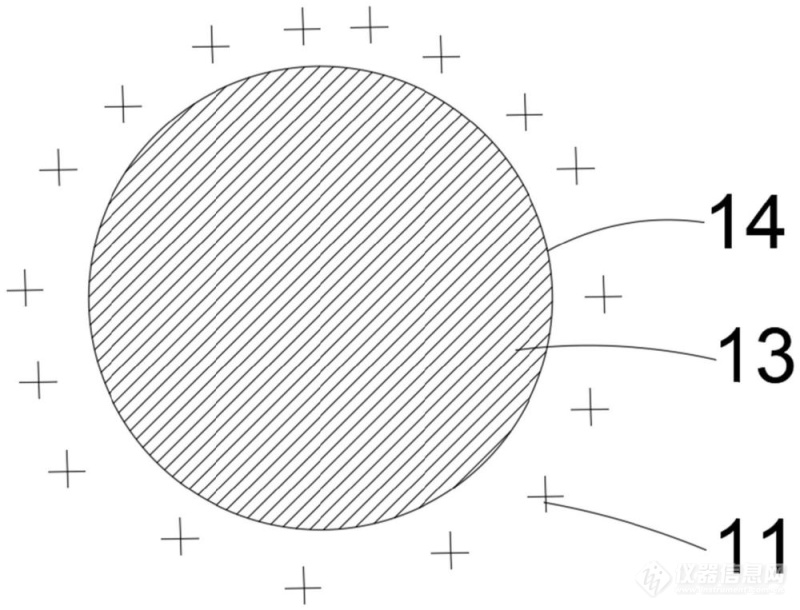

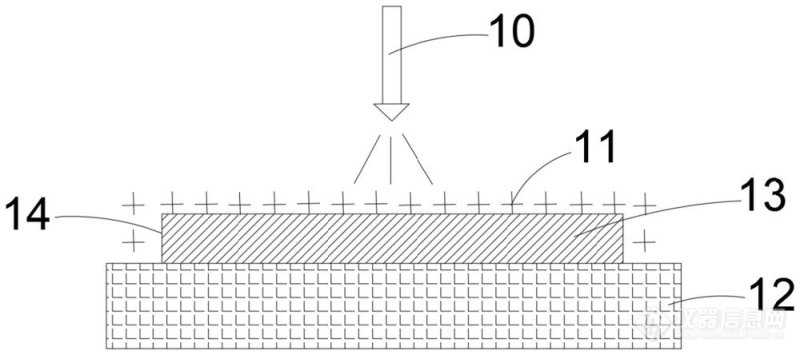

Background technique In the semiconductor manufacturing process, a measuring machine is needed to detect the equivalent capacitance thickness (CET), surface damage (PDM), surface barrier voltage (VSB), surface interface state density (LI) and other related parameters of the wafer through the capacitance-voltage characteristic curve, namely the CV characteristic curve, so as to characterize the quality of the wafer surface film, namely the dielectric layer. The wafer detector (Semiconductor Diagnostics Inc, SDI) uses a corona gun to excite the charge on the surface of the wafer, namely the dielectric layer, and uses a non-contact vibration probe to measure the surface voltage, and makes a CV characteristic curve to analyze the quality of the wafer surface film. In the actual measurement process of SDI, as shown in FIG1 and FIG2, the charges 11 excited by the corona gun 10 will hit the surface of the wafer 13 placed on the carrier 12, but part of the charges 11 at the edge 14 of the wafer will be offset, causing the charges 11 to appear outside the edge 14 of the wafer. The edge 14 of the wafer is prone to leakage due to the loss of charges 11, resulting in abnormal measurement data. Therefore, it is necessary to provide a new type of wafer carrier and semiconductor detection system to solve the above problems existing in the prior art..

Schematic side view of the charge generated by the corona gun in the prior art being offset at the edge of the wafer..

Schematic diagram of the top view of the charge generated by the corona gun being offset at the edge of the wafer