Is there an English version?The best site to learn about semiconductor progress in China

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese semiconductor industry

- Thread starter Hendrik_2000

- Start date

- Status

- Not open for further replies.

Appreciation is really bad for exports and favor imports. Not sure it is a good idea.They can just allow the rmb to appreciate 5% per year for the next decade. This would send US inflation way up and their stock market into disarray. The large amount of money printing will tank the $US.

Google chrome translator feature does a good job translating from Chinese to English.Is there an English version?

@horse bro from MOTIF (CHINA MILITARY FORUM), I hope one day he join this forum, it will be a blast....LOL

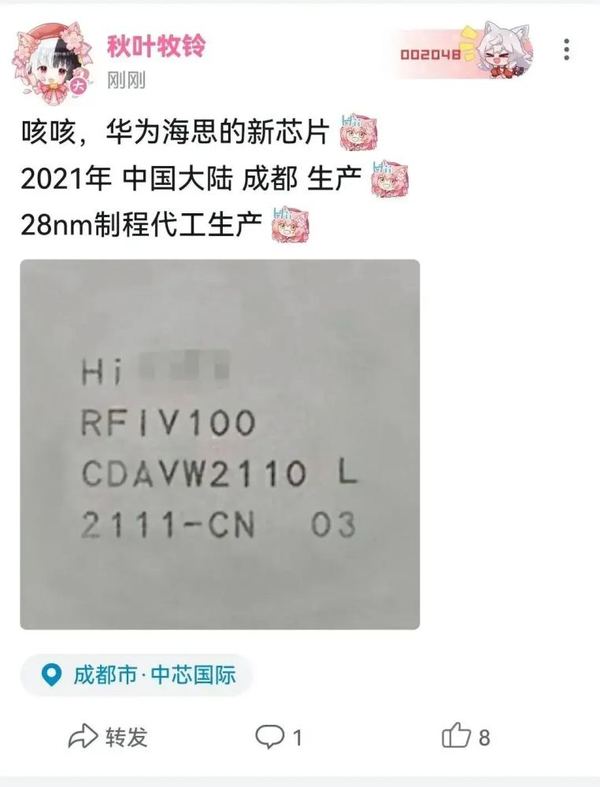

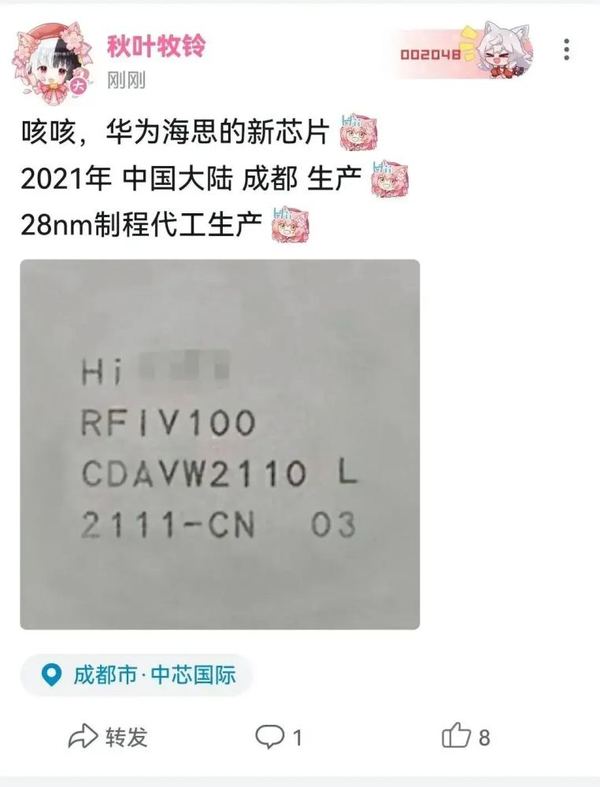

Reportedly, SMIC foundry fabricated HiSilicon 28nm chip for Huawei using a domestic line free of US technology.

近日有一张华为海思的28nm制程芯片流出,代工厂商为成都中芯国际。不要小看这一个信息,在华为遭受禁令的前提下依然能为华为代工生产芯片,那就说明在28nm制程这个节点上已经完成了技术国产化。

28nm可不是一个普通的工艺节点,这是先进工艺和成熟工艺的分水岭。台积电在2011年完成了28nm,中芯国际在2015年攻克了28nm,而现在这块芯片则是完成了“去美化”的28nm芯片,这也意味着在28nm节点上卡脖子的问题已经基本得到解决。

Huawei is a very powerful company with its own core technology. It has developed the Kirin series of chips and the Harmony system. With its own strength, it has been loved by consumers. Huawei's self-developed chips are still very powerful, after all. There are not many companies that have self-developed chips. If foreign companies stop selling chips to domestic companies, there may be no core available, and Huawei can be completely self-sufficient.

But in order to restrict the development of domestic high-tech companies such as Huawei, a certain country implemented a chip ban, which not only restricted Huawei from purchasing chips from overseas, but also cut off the foundry channels of HiSilicon's self-developed chips. TSMC also stopped cooperation with Huawei. Although they have the technology to make chips, they can't find a suitable company for foundry. As a result, Huawei has not enough chips, and their market share has dropped a lot.

Ren Zhengfei, the founder of Huawei, said in an interview that HiSilicon can design excellent chips, but the domestic market has insufficient manufacturing capabilities, and they cannot find a suitable contract processing company. Yu Chengdong also expressed regret that he did not place heavy assets. Chip manufacturing is included in the development plan.

In fact, Huawei's restriction is not necessarily a bad thing. This can affect them in a short period of time, but in the long run, it will drive the comprehensive high-end development of China Chip and make the development of China's semiconductor industry better and better. After all, there is pressure. With motivation, the domestic market is constantly improving the shortcomings of chip manufacturing, striving to no longer be controlled by others in the future.

SMIC is a very powerful foundry company. Although it is not as good as TSMC and other companies for the time being, SMIC's progress is still very obvious. It only took about 3 years to progress from 90nm chip process to 14nm. At the level of the manufacturing process, 7nm has also completed the technological development, and the yield rate is still very high.

It is worth noting that I have developed a 28nm chip. This chip is likely to be foundry by SMIC, but this chip is not a 5nm process 5G mobile chip like Kirin 9000, but an OLED driver chip with only 28nm process. Qualcomm was caught off guard. After all, Qualcomm's Snapdragon series chips and Huawei's Kirin series chips are competitors. After Huawei gains an advantage, it is not a good thing for Qualcomm.

If Huawei and SMIC cooperate, it is not just a problem of chip breakthroughs, it can be said to be a mutually beneficial and win-win thing, but some netizens have also raised questions, that is why it is not the 5nm that is urgently needed for mobile phones, but from OLED What about the driver chip? South Korean companies occupy a relatively high market share in this field. Domestic OLED driver chips are mainly imported. This time the chip breakthrough will increase the domestic market share.

If SMIC can OEM for Huawei, then its production line will be upgraded. Huawei's breakthrough not only means its own achievements on chips, but also represents the progress of the domestic semiconductor industry, and the significance is still relatively large. of. In fact, the development of our manufacturing industry has gradually become a trend, and the popularity in the future is likely to surpass that of light asset industries such as the Internet and live streaming.

Reportedly, SMIC foundry fabricated HiSilicon 28nm chip for Huawei using a domestic line free of US technology.

近日有一张华为海思的28nm制程芯片流出,代工厂商为成都中芯国际。不要小看这一个信息,在华为遭受禁令的前提下依然能为华为代工生产芯片,那就说明在28nm制程这个节点上已经完成了技术国产化。

28nm可不是一个普通的工艺节点,这是先进工艺和成熟工艺的分水岭。台积电在2011年完成了28nm,中芯国际在2015年攻克了28nm,而现在这块芯片则是完成了“去美化”的28nm芯片,这也意味着在28nm节点上卡脖子的问题已经基本得到解决。

Huawei's self-developed 28nm chip, foundry by SMIC?Qualcomm caught off guard, not just a chip problem

2021-08-22 14:25:04 HKTHuawei is a very powerful company with its own core technology. It has developed the Kirin series of chips and the Harmony system. With its own strength, it has been loved by consumers. Huawei's self-developed chips are still very powerful, after all. There are not many companies that have self-developed chips. If foreign companies stop selling chips to domestic companies, there may be no core available, and Huawei can be completely self-sufficient.

But in order to restrict the development of domestic high-tech companies such as Huawei, a certain country implemented a chip ban, which not only restricted Huawei from purchasing chips from overseas, but also cut off the foundry channels of HiSilicon's self-developed chips. TSMC also stopped cooperation with Huawei. Although they have the technology to make chips, they can't find a suitable company for foundry. As a result, Huawei has not enough chips, and their market share has dropped a lot.

Ren Zhengfei, the founder of Huawei, said in an interview that HiSilicon can design excellent chips, but the domestic market has insufficient manufacturing capabilities, and they cannot find a suitable contract processing company. Yu Chengdong also expressed regret that he did not place heavy assets. Chip manufacturing is included in the development plan.

In fact, Huawei's restriction is not necessarily a bad thing. This can affect them in a short period of time, but in the long run, it will drive the comprehensive high-end development of China Chip and make the development of China's semiconductor industry better and better. After all, there is pressure. With motivation, the domestic market is constantly improving the shortcomings of chip manufacturing, striving to no longer be controlled by others in the future.

SMIC is a very powerful foundry company. Although it is not as good as TSMC and other companies for the time being, SMIC's progress is still very obvious. It only took about 3 years to progress from 90nm chip process to 14nm. At the level of the manufacturing process, 7nm has also completed the technological development, and the yield rate is still very high.

It is worth noting that I have developed a 28nm chip. This chip is likely to be foundry by SMIC, but this chip is not a 5nm process 5G mobile chip like Kirin 9000, but an OLED driver chip with only 28nm process. Qualcomm was caught off guard. After all, Qualcomm's Snapdragon series chips and Huawei's Kirin series chips are competitors. After Huawei gains an advantage, it is not a good thing for Qualcomm.

If Huawei and SMIC cooperate, it is not just a problem of chip breakthroughs, it can be said to be a mutually beneficial and win-win thing, but some netizens have also raised questions, that is why it is not the 5nm that is urgently needed for mobile phones, but from OLED What about the driver chip? South Korean companies occupy a relatively high market share in this field. Domestic OLED driver chips are mainly imported. This time the chip breakthrough will increase the domestic market share.

If SMIC can OEM for Huawei, then its production line will be upgraded. Huawei's breakthrough not only means its own achievements on chips, but also represents the progress of the domestic semiconductor industry, and the significance is still relatively large. of. In fact, the development of our manufacturing industry has gradually become a trend, and the popularity in the future is likely to surpass that of light asset industries such as the Internet and live streaming.

So SMIC N+2 the true 7nm is about to go to trial production as stated in the article, hope it will be successful, if it does will SMIC risk sanction and produce it? Or they're confident that the domestic equipment will be available? As we know with a few tweak if you master the 14nm finfet tech going down 7nm is much easier especially if SMEE 28 DUVL can deliver as advertise.

Recently, some media reported that SMIC is about to trial-produce 7nm chips this month, and strive to achieve mass production targets in October this year. It is understood that SMIC's trial production of 7nm chips is not using advanced EUV lithography machines, but plans to trial production of 7nm chips through the DUV process. At present, semiconductor manufacturers that have achieved 7nm chip production in the world basically use EUV lithography machines for production. However, because Chinese semiconductor companies lack such advanced lithography machines, SMIC can only achieve this through DUV lithography machines. The goal of mass production of 7nm chips.

As the largest and most technologically advanced integrated circuit manufacturer in mainland China, SMIC's position in the domestic semiconductor field is very high. The industry has always regarded it as the core force to break through the localization of semiconductors. Trial production of the 7nm process has attracted expectations from all walks of life. If SMIC really achieves mass production of the 7nm process, its significance is very significant. It will not only greatly enhance SMIC's position in the international semiconductor field, but also It also means that the core shortage dilemma that Huawei is facing is expected to be resolved.

Although the current chip technology has developed to 3nm and 2nm, and even some semiconductor manufacturers have prepared to advance to the process below 1nm, that is, the Amy process, in fact, in all advanced processes, the process that has achieved mass production has only reached 5nm. And there are only a handful of semiconductor manufacturers in the world. Even the semiconductor giant Intel is still stuck at 7nm and has not broken through 5nm. If SMIC successfully mass-produces 7nm chips, it may not be able to compare with established foundries such as TSMC and Samsung in terms of yield and capacity, but it should not be difficult to meet domestic market demand.

As far as the current chip market is concerned, the market demand for the 7nm process is very large. Many of Huawei's Kirin chips are based on the 7nm process, such as Kirin 990 and Kirin 990 5G. As the United States cut the supply of Huawei's chips, Huawei's 7nm chips are actually in a state of being out of supply. Therefore, SMIC's mass production of 7nm chips is of great significance to Huawei. This is related to whether Huawei's chip crisis can be effectively alleviated. It is worth mentioning that, as the domestic chip industry is showing a blowout development, in addition to Huawei, many domestic companies' chip orders have flocked to SMIC. It is conceivable that after SMIC achieves mass production of 7nm chips, Its orders will be full again, and its production capacity may even enter a state of full load.

I have to admit that the development speed of SMIC has been getting faster and faster in recent years, especially after entering 2021. In February and March of this year, SMIC frequently reported good news, allowing China's semiconductor industry to see the realization of semiconductors. The hope of localization. Although it started late, the strength of SMIC is undeniable. Take its latest breakthrough 14nm process. With continuous research and development, the yield rate of SMIC's 14nm process has increased to about 95%, and it can be compared with TSMC. Samsung Electronics is comparable. I believe that this time SMIC can create surprises again, break through the 7nm process, and help the development of "China Core".

Read the latest global technology and analyze industry trends in depth

SMIC is about to trial-produce 7nm chips. Will Huawei's core shortage problem be solved?

2021-08-25 23:52:59 HKTRecently, some media reported that SMIC is about to trial-produce 7nm chips this month, and strive to achieve mass production targets in October this year. It is understood that SMIC's trial production of 7nm chips is not using advanced EUV lithography machines, but plans to trial production of 7nm chips through the DUV process. At present, semiconductor manufacturers that have achieved 7nm chip production in the world basically use EUV lithography machines for production. However, because Chinese semiconductor companies lack such advanced lithography machines, SMIC can only achieve this through DUV lithography machines. The goal of mass production of 7nm chips.

As the largest and most technologically advanced integrated circuit manufacturer in mainland China, SMIC's position in the domestic semiconductor field is very high. The industry has always regarded it as the core force to break through the localization of semiconductors. Trial production of the 7nm process has attracted expectations from all walks of life. If SMIC really achieves mass production of the 7nm process, its significance is very significant. It will not only greatly enhance SMIC's position in the international semiconductor field, but also It also means that the core shortage dilemma that Huawei is facing is expected to be resolved.

Although the current chip technology has developed to 3nm and 2nm, and even some semiconductor manufacturers have prepared to advance to the process below 1nm, that is, the Amy process, in fact, in all advanced processes, the process that has achieved mass production has only reached 5nm. And there are only a handful of semiconductor manufacturers in the world. Even the semiconductor giant Intel is still stuck at 7nm and has not broken through 5nm. If SMIC successfully mass-produces 7nm chips, it may not be able to compare with established foundries such as TSMC and Samsung in terms of yield and capacity, but it should not be difficult to meet domestic market demand.

As far as the current chip market is concerned, the market demand for the 7nm process is very large. Many of Huawei's Kirin chips are based on the 7nm process, such as Kirin 990 and Kirin 990 5G. As the United States cut the supply of Huawei's chips, Huawei's 7nm chips are actually in a state of being out of supply. Therefore, SMIC's mass production of 7nm chips is of great significance to Huawei. This is related to whether Huawei's chip crisis can be effectively alleviated. It is worth mentioning that, as the domestic chip industry is showing a blowout development, in addition to Huawei, many domestic companies' chip orders have flocked to SMIC. It is conceivable that after SMIC achieves mass production of 7nm chips, Its orders will be full again, and its production capacity may even enter a state of full load.

I have to admit that the development speed of SMIC has been getting faster and faster in recent years, especially after entering 2021. In February and March of this year, SMIC frequently reported good news, allowing China's semiconductor industry to see the realization of semiconductors. The hope of localization. Although it started late, the strength of SMIC is undeniable. Take its latest breakthrough 14nm process. With continuous research and development, the yield rate of SMIC's 14nm process has increased to about 95%, and it can be compared with TSMC. Samsung Electronics is comparable. I believe that this time SMIC can create surprises again, break through the 7nm process, and help the development of "China Core".

Read the latest global technology and analyze industry trends in depth

the 28-hectare site will feature a research & development center, manufacturing plant and staff accommodation

The housing project will deliver 580,000 square meters of accommodation for its high-end talent which will be priced at just CNY12,000 (USD1,853) per square meter, much less than neighboring properties that cost in the range of CNY45,000 per sqm

AssassinsMace

Lieutenant General

As usual the US thought it was playing a game of chicken where Americans think they have an edge by threatening to deny themselves from the Chinese which would plunge China into disarray and force a surrender to US demands before everyone found out it it would never be the case.

Absolutely agreed. I just can't see everybody else in the world does not see this. China IS THE MARKET. It is just import substitution. If nobody else built any fab there would already be a colossal glut, simply because the rest of the foundries could no longer sell to China. On top of that they are building fabs like nuts. I really can't see who they are going to seel to.It's not that China will flood the market but rather that China's domestic semiconductor production will start to seriously damage semiconductor imports into China, sometime between 2023-2024. The effect on the already alarming global fab overcapacity at that time will be dramatically magnified. Profits aren't made until fixed + variable costs are covered. It is impossible for these costs, let alone R&D, to be recouped if China comes anywhere close to self-sufficiency when China represents well over half the world's semiconductor consumption (domestic+re-export). When the current manic construction of fab capacity is completed between now and 2024, it will be synchronized with China's semiconductor self-sufficiency >=14nm. It will take time for China to ramp up scale but even so, sometime between 2026-2027, this will result in idle global fab capacity of something approaching 50% with costs increasing globally as reshoring happens in the US, Europe and Japan, all while margins crater. For those semiconductor companies who don't merge or go bankrupt, there will be the remainder who will be slashing multiyear R&D costs across the board. This will slow down semiconductor tech advance at the leading edge at the same time that China completely catches up in DUV and begins gradually catching up everywhere else at lower costs.

This is a nightmare scenario for the global semiconductor industry and nirvana for China's domestic industry. However, there's always the probability where the Anglo-American alliance engineer political and/or military solutions. I think this is highly likely given that they never seem to learn.

I wonder what happens if the employee leaves the company. Is the house his or does he have to return to the company?

the 28-hectare site will feature a research & development center, manufacturing plant and staff accommodation

The housing project will deliver 580,000 square meters of accommodation for its high-end talent which will be priced at just CNY12,000 (USD1,853) per square meter, much less than neighboring properties that cost in the range of CNY45,000 per sqm

Principle of communicating vases.Can someone explain why in a thread for Semiconductors there is discussion about Afghanistan, US Hegemony, Taiwan Strait, China having a demographic crisis, banning China from SWIFT, war over Taiwan, CIA destabilizing China etc ?

You don't need to look much further:Just ignore him

Reality will catch up sonner or later.

I wonder when Fully Chinese consumer CPUs and GPUs will become available. The insane markups for the GPUs here in the west is a great opportunity for GPU newcomers but I'm not sure how long it'll last.

It doesn't even need to be cutting edge either, the most common GPUs on steam are still the GTX 1000s and 1600s, which were made on 16, 14 and 12nm processes. A Chinese GPU thats competitive against those but actually in stock would be great.

And mind you it uses LongArch Instruction Set.

Property ownership is actually stronger in China than the West. There is no property tax at all! In the West you never own the house even after paying off the mortgage, you have to pay rent to the government in the form of property taxes. This is not the case in China.I wonder what happens if the employee leaves the company. Is the house his or does he have to return to the company?

- Status

- Not open for further replies.