Suzhou Sudavig Technology Group Co., Ltd. (Sudavig for short) is a national high-tech enterprise dedicated to the innovative application of micro-nano key technologies, flexible intelligent manufacturing, and flexible optoelectronic materials.

After years of development, Sudavig has become a typical enterprise of independent innovation in the fields of micro-nano optoelectronic materials, new displays and nano-printing, involving micro-nano optical printing materials, nano-printing, 3D imaging materials, flat panel display (large-size capacitive touch screen, ultra-thin conductive Light board), high-end intelligent micro-nano equipment (nano-imprinting, micro-nano direct writing lithography, 3D light field printing, etc.) R & D and industrialization, listed on the Shenzhen Stock Exchange A-share GEM (Su Daweige 300331).

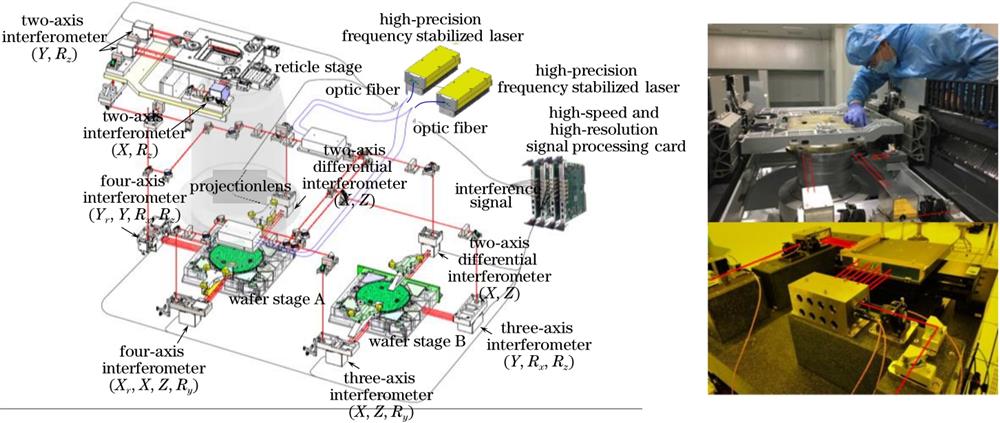

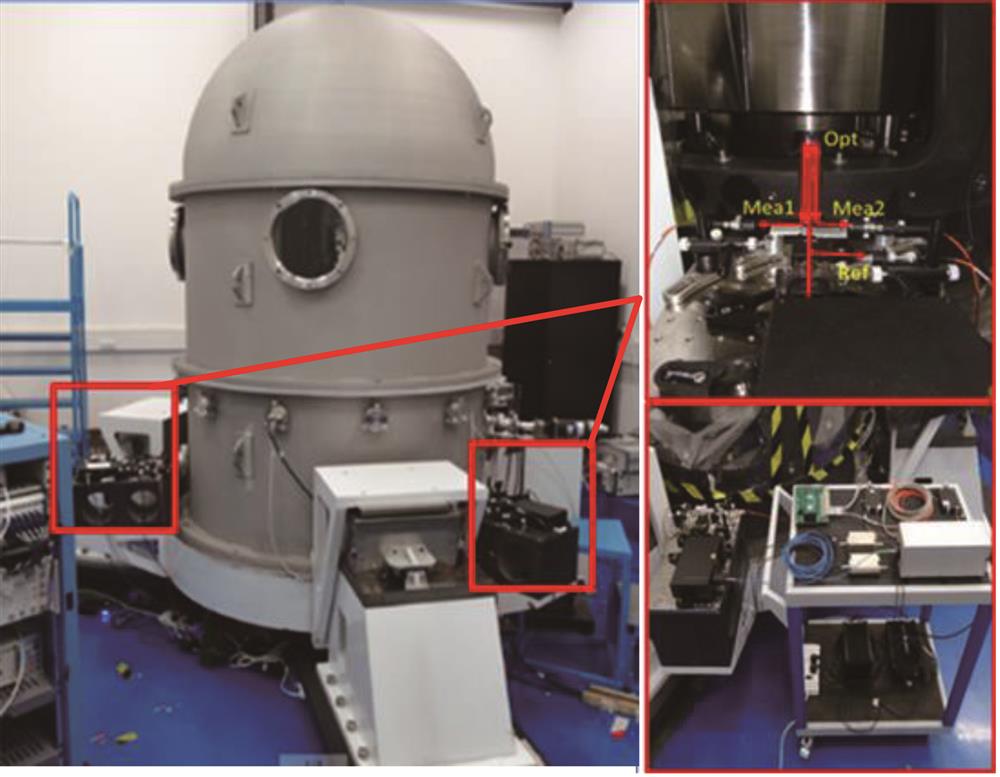

This guys are less well known, but they do patterning tools for large area micro and nanofabrication but also for IC, MEMs and other areas. They are involved in Maskless direct laser writting lithography and nanoImprint lithography.

After years of development, Sudavig has become a typical enterprise of independent innovation in the fields of micro-nano optoelectronic materials, new displays and nano-printing, involving micro-nano optical printing materials, nano-printing, 3D imaging materials, flat panel display (large-size capacitive touch screen, ultra-thin conductive Light board), high-end intelligent micro-nano equipment (nano-imprinting, micro-nano direct writing lithography, 3D light field printing, etc.) R & D and industrialization, listed on the Shenzhen Stock Exchange A-share GEM (Su Daweige 300331).

This guys are less well known, but they do patterning tools for large area micro and nanofabrication but also for IC, MEMs and other areas. They are involved in Maskless direct laser writting lithography and nanoImprint lithography.