You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese semiconductor industry

- Thread starter Hendrik_2000

- Start date

- Status

- Not open for further replies.

I know that your intentions are pure but articles about U-precision are becoming a bit old and repetitive. Just a small request.4th time? I did a search and found no other posts. Also, I do not advertise, this is just a post to give an insight on what China's SME industry is working on.

broadsword

Brigadier

I know that your intentions are pure but articles about U-precision are becoming a bit old and repetitive. Just a small request.

He did say he did not find similar post before posting.

Chinese semiconductor industry

Quickie

Colonel

I know that your intentions are pure but articles about U-precision are becoming a bit old and repetitive. Just a small request.

Not for most of us.

I personally don't mind a bit of a repost just in case I might have missed it the first time around which is exactly the case for me for that U-precision post.

I've always been thinking: How did they decide on 13.5 nm? I mean this seems like a dumb question but really, how was this specific number chosen?

After all, they didn't really know what they were looking for when EUV lithography was being designed. but up to So why would they pick this specific wavelength as early as 2001 even though in 2001 the most advanced processes were on 0.13 micron, using KrF lithography, and general processes were on 0.35 micron with i-line mercury lamp lithography???

Indeed, even now the 13.5 nm EUV lithography is neither coherent or monochromatic (the advantages of excimer sources), and only ~3% energy efficient. 13.5 nm has other problems: secondary electron generation and diffusion makes for 'fuzzy' lines that somewhat negate the finer line widths possible, it is absorbed by all materials, it requires reflection only optics, it is best with grazing incidence optics like X-rays, etc.

If I were looking at this from the outside, it wouldn't have been obvious to me that specifically 13.5 nm was a good choice for a wavelength. Indeed, the light source development alone took almost 20 years.

If that's the case, then should a synchrotron source which has a tunable wavelength really stick with 13.5 nm?

After all, they didn't really know what they were looking for when EUV lithography was being designed. but up to So why would they pick this specific wavelength as early as 2001 even though in 2001 the most advanced processes were on 0.13 micron, using KrF lithography, and general processes were on 0.35 micron with i-line mercury lamp lithography???

Indeed, even now the 13.5 nm EUV lithography is neither coherent or monochromatic (the advantages of excimer sources), and only ~3% energy efficient. 13.5 nm has other problems: secondary electron generation and diffusion makes for 'fuzzy' lines that somewhat negate the finer line widths possible, it is absorbed by all materials, it requires reflection only optics, it is best with grazing incidence optics like X-rays, etc.

If I were looking at this from the outside, it wouldn't have been obvious to me that specifically 13.5 nm was a good choice for a wavelength. Indeed, the light source development alone took almost 20 years.

If that's the case, then should a synchrotron source which has a tunable wavelength really stick with 13.5 nm?

@Quickie bro ever since @tokenanalyst @FairAndUnbiased @krautmeister @huemens join this forum, this thread had become more livelier and more interesting, I join this forum because of @WTAN @foofy and @Oldschool and I learned a lot, with them on board maybe I can take and pass my engineering exam with flying colors and I'm not joking...lolNot for most of us.

I personally don't mind a bit of a repost just in case I might have missed it the first time around which is exactly the case for me for that U-precision post.

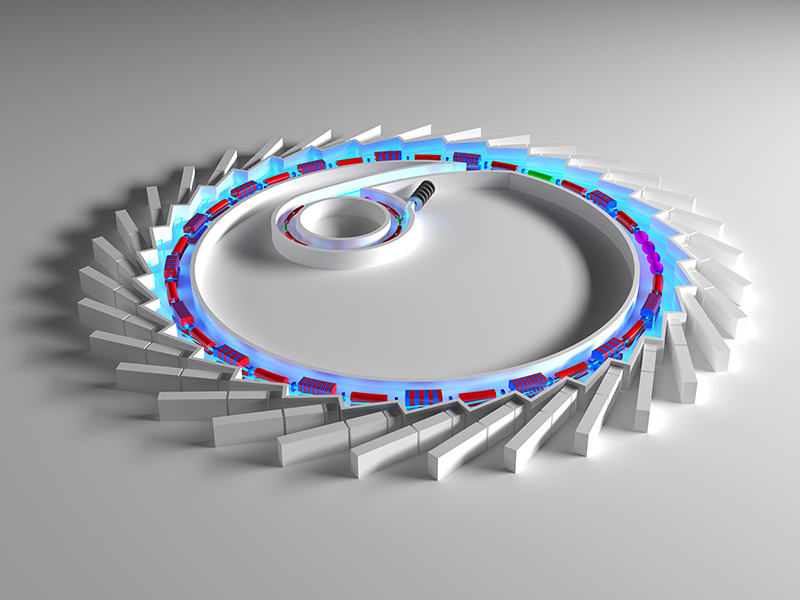

yes, 1 beamline = 1 EUV machine. Here's a diagram of what a synchrotron beamlines looks like.

It would change fab layout and increase fab construction costs. It would also increase the difficulty of multiple EUV steps, since 1 mask = 1 step = 1 layer. However, in exchange you can have economies of scale with multiple EUV optics sets being serviced with 1 synchrotron. How many EUV instruments do you need?

At some point the cost of adding another EUV source (~$50 million per source) will outweigh the cost of having 1 big synchrotron ($172 million per 8 beamlines for the Shanghai synchrotron or $25 million per source if you use all 8).

So if I look at EUV sales, it looks like ASML is at 50 machines per year.

Ok. So would it be fair to say that a single fab can use at least 8 beamlines? Or 16/24 beamlines?

And what is the uptime for a synchrotron?

Then mass-producing synchotrons is doable, if the overall cost is only half as much as the equivalent ASML EUV machines.

@AndrewS Sir that number is to optimistic, with supply chain issue and a fire in one of its critical supplier, it will be a miracle if they're able to deliver what they promise?So if I look at EUV sales, it looks like ASML is at 50 machines per year.

Ok. So would it be fair to say that a single fab can use at least 8 beamlines? Or 16/24 beamlines?

And what is the uptime for a synchrotron?

Then mass-producing synchotrons is doable, if the overall cost is only half as much as the equivalent ASML EUV machines.

Nah, Chinese equipments are 10 times cheaperNot good enough. Lets hope that they drastically increase CapEx in 2023

View attachment 82627

- Status

- Not open for further replies.