As the Americans already found out and is in total panic, Huawei will fab themBig question is who will fab them???? Has Huewei has a magic solution???? Let's hope n wish for the best.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese semiconductor industry

- Thread starter Hendrik_2000

- Start date

- Status

- Not open for further replies.

I would think it a 150 million industry by your example. The 100m paid to the Chinese company is the cost of the European company. It probably should not be counted again in the final output of the whole industry (which is the 150m sales price of all the chips).How does mixing Fabless companies like AMD and Pure-play companies like TSMC, work for this kind of comparison. Is it even realistic to mix sales from these two different type of companies?

For example, for a thought experiment imagine there are only two semi companies in the world. One is a Fabless company in Europe another is a Pure-play foundry in China. European company orders 100 million worth of chips from Chinese company. European company then adds a 50 million margin and sells the chips for 150 million. Now would you consider this a 150 million dollar industry (China 100 + Europe 50 ), or would it be considered a 250 million industry (China 100 + Europe 150). In the first scenario you would say China has a 66% market share. In the second scenario you would say China has only a 40% market share.

The article says china has 9% market share and Europe and Japan has 10% market share each. But I imagine China's fab output would be already higher than Europe

coolieno99

Junior Member

One of the brightest software engineer at Facebook is a very young Chinese .... Look no further to the success of companies like Google, Facebook, and Amazon to see the value of software. The kind of money these companies bring in can power entire industries and strengthen the finances and economies of the countries they are based in. ...

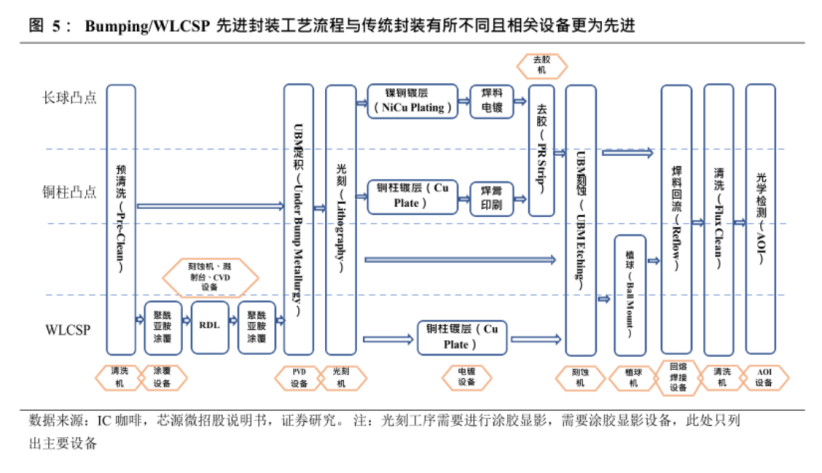

A senior executive of a domestic advanced packaging equipment factory introduced to the author that the main difference between traditional packaging and advanced packaging is that the former "is to carry out post-processing such as patching and then wire bonding", while the latter combines patching and wire bonding into one process. Afterwards, according to the difference in technology, for example, to do flip chip, it is necessary to use the front-end manufacturing process such as ball mounting, electroplating, photolithography, etching, etc., which also brings about the difference of equipment.

Just as foundries are well-positioned, advanced packaging equipment is moving closer to front-end equipment. Since advanced packaging is more performed on the wafer level, the front-end manufacturing method is used to make the back-end connection circuit, and the similarity of the process flow makes the equipment used in the two roughly the same, except for flip-chip, such as 2.5D/3D package TSV The technology requires photolithography machines, gluing eye shadow equipment, wet etching equipment, etc.

This kind of equipment, which is required in both front-end manufacturing and back-end advanced packaging, has a unified name in the industry, that is, "middle way equipment", but from the current participants in the track, it is still the original Qiandao Equipment Factory dominates. The above-mentioned industry insiders said that because they are more familiar with the front-end process, compared with the traditional back-end packaging equipment factory, the front-end equipment factory has more advantages in this field .

Looks like packaging Lithography is in road to become as complicated as Front-End lithography with the rise of 3D packaging and other advanced processes. Strong opportunities for SMEE in this sector.

At present, Sxsaw occupies more than 40% of the market share for traditional SAW filters, including wireless microphones and remote control modules.

Nano-Core Chip has four international leading technical systems in the field of AIoT chips, including ultra-low power event-driven chip architecture, closed-loop adaptive near-threshold circuit, ultra-low power high-precision sensing technology and high-energy-efficient embedded AI engine technology.

Nano-Core Chip has four international leading technical systems in the field of AIoT chips, including ultra-low power event-driven chip architecture, closed-loop adaptive near-threshold circuit, ultra-low power high-precision sensing technology and high-energy-efficient embedded AI engine technology.

I don't know IF the US had Orchestrated the fire on ASML plant, I'm not a paranoid person to instantly believed a conspiracy theory. BUT maybe there is (total ban) policy wise and another is SMEE SSA800 DUVL machine, it forces ASML hands. The expanded production is the Culprit , trying to satisfy SMIC demand while the Iron is still Hot. You may not see what I see and it enhance the discussion with a different view point, BUT again it is a microcosm of China economic and technological development, as the Western monopoly hold is being challenge, they were forced to do things that is outside their comfort zone. The parasitic behavior of complacency and condescending attitude is what ails the West.

CC

364 views4 hours ago

CC

@gelgoog thanks bro we have the same conclusion, so maybe with these unintended mishap, will that force ASML to diversify its supply chain? why not use Gigaphoton light source in the China market? since DUVL is allowed why not use some Chinese parts? There are many possibilities IF one is serious and IF the intended goal is to remain in China then embedded to it. That is sure and concrete signal rather than giving statement that further complicate things.The news are that ASML DUV production won't be impacted, but EUV production will. So this should have no impact on SMIC.

SMEE SSA800 is a monopoly disruptor, Yes for the doubters out there IT'S REAL and coming to you sooner than you thought (brave words, BUT I'm confident). For the US to have a debate rather than outright action shows that ASML is pushing and pushing back hard and is winning. My opinion ASML dealing with SMIC is in a critical junction, IF ASML gave in not only they lost their Chinese customers BUT those foreign FAB makers in China like TSMC ,SK HYNIC, UMC and others. And they (foreign FAB) are what concern ASML the most, they will be forced to use SMEE equipment and then they will have the power to bargain and Questioning their pricing policy and making further concession. You know having a competitor, losing your pricing power and force to negotiate, for a monopoly company that is Very hard to take...lol

- Status

- Not open for further replies.