Dizasta1

Senior Member

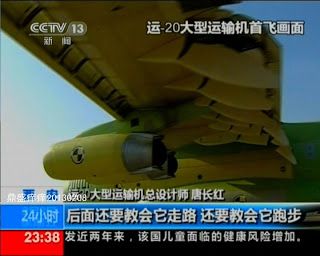

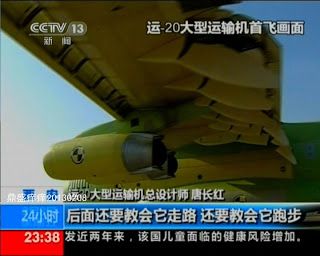

Close up shots of the Y-20 heavy transport

Simply beautiful!

Close up shots of the Y-20 heavy transport

On Jan. 26, China successfully completed the maiden flight of Y-20, a heavy military freighter independently developed by China. The success of Y-20’s first test flight marks that China has become the fourth country to be able to make 200-ton scale military air freighter.

It is reported that part of the interior components of the Y-20 are made of the anti-flaming glass fiber reinforced epoxy resin and glass fiber reinforced phenolic resin prepreg composite, the development of which was led by the No. 703 office of No.1 institute of CASC and with the joint participation of many other units of this cooperation.

Combining the advantages of high specific strength and high specific stiffness of composite, anti-flaming and low smoke properties, this cabin design does not only successfully help reduce the weight of aircraft structure, improve the fire proof efficiency, but also has broken up the unfavorable situation that the large scale domestic aircraft has to adopt imported prepreg composite, realizing the requirement for “focusing on domestic market, self-sufficiency” of domestic large scale aircraft cabin and increasing the safety and economic efficiency of the whole aircraft body.

Driven by the demand for large aircraft represented by the Y-20, No. 703 office and its brother offices have carried out the research and development of those two kinds of prepreg composites, providing the interior components raw materials for the large aircraft.

Since the project gained approval in March 2009, through three years’ efforts, No. 703 office has successfully developed two kinds of aviation-grade high uniformity satin weave glass fiber fabric whose performance is on par with similar foreign products, fully satisfying the requirements of the fire-retardant materials for cabin interior.

In addition to the materials used on the Y-20, 703 office and other units also have realized at home for the first time a comprehensive performance test required by foreign material specifications, completing the evaluation system for large domestic aircraft cabin interior composites, breaking the monopoly of discourse power of foreign countries on the evaluation of material performance.

With the launching of the follow-up tasks of the Y-20, it is estimated that there will be hundreds of purchase contracts. Besides, CASC shall utilize the manufacturing advantage of aerospace military industry and continue achieving the win-win situation of both parties.