Hendrik_2000

Lieutenant General

At the height of flood season the western press hype the impending burst of three gorge dam and the accompanying disaster downstream But nothing happened that should be testament to the skill of Chinese dam builder

China's Three Gorges passes all tests, effective in flood control, power generation

Source: Global Times Published: 2020/11/1 15:03:03 Last Updated: 2020/11/1 15:54:16

China announced Sunday the full completion of the Three Gorges project, and that it had passed all tests. The dam and reservoir are running smoothly and fully operational in flood control, power generation, navigation and water resources utilization, a sharp rebuke to long-held Western hype and suspicions that it is at risk of collapse and poses a danger to the environment.

The Three Gorges Project is by far the world's largest water control project and the most comprehensive hydropower project, Chinese officials from the Ministry of Water Resources and National Development and Reform Commission announced on Sunday.

Monitoring shows that the river dam, flood discharge, energy dissipation, water diversion and power generation, navigation facilities and protective buildings are in normal operating condition. The mechanical and electrical systems and equipment, and metal structure equipment are also operating safely and stably, they said.

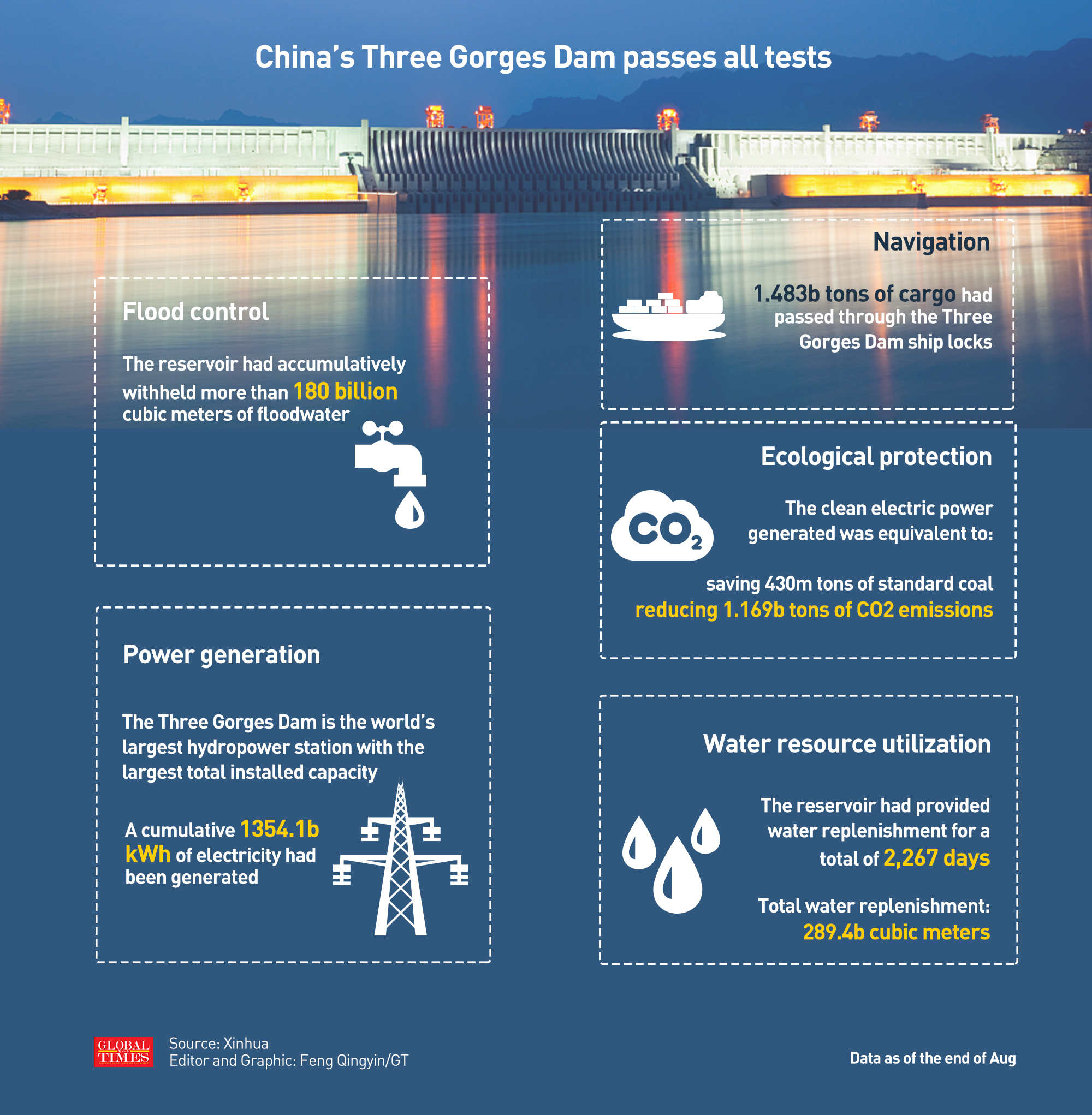

Infographic:GT

In terms of flood control, by the end of August, the Three Gorges Reservoir had accumulated more than 180 billion cubic meters of floodwater. In 2010, 2012 and 2020, the maximum flood peak exceeded 70,000 cubic meters per second. Through the retention by the reservoir, the flood peak was reduced by about 40 percent, greatly reducing the flood control pressure in the middle and lower reaches of the Yangtze River.

The Three Gorges Power Station is also the world's largest hydropower station with the largest total installed capacity. By the end of August, the Three Gorges Power Station had generated 1.354 trillion kilowatt-hours of electricity, boosting power supply in East China, Central China and South China's Guangdong Province and other regions. The reservoir has also become an important large-scale clean energy production base in China.

The project has significantly improved the navigation conditions of the Sichuan River waterway. Since trial navigation in June 2003, the freight volume of the Three Gorges Dam ship locks has increased rapidly, exceeding 100 million tons for the first time in 2011 and reaching 146 million tons in 2019. By the end of August, a total of 1.483 billion tons of cargo had passed through the sluice, giving a strong boost to the development of the Yangtze River Economic Belt.

Photo taken on Aug. 19, 2020 shows water gushing out from the Three Gorges Dam in central China's Hubei Province. Photo: Xinhua

The annual discharge of the Three Gorges Reservoir during the dry season has been raised to more than 5,500 cubic meters per second, bringing replenishment of more than 20 billion cubic meters of water for the middle and lower reaches of the Yangtze River.

By the end of August, the reservoir had provided replenishment for a total of 2,267 days, with a total water supply of 289.4 billion cubic meters, improving the production, living and ecological water conditions in the middle and lower reaches of the Yangtze River.

Also by the end of August, the high-quality clean power generated by the Three Gorges Power Station will be equivalent to saving 430 million tons of standard coal and 1.169 billion tons of carbon dioxide emissions, representing significant benefits in energy conservation and emission reduction.

Officials announced that a total of 1.3 million residents had been relocated during the construction of the project, significantly improving their living conditions. The geological environment of the resettlement area as well as the reservoir are generally safe.

Global Times

China's Three Gorges passes all tests, effective in flood control, power generation

Source: Global Times Published: 2020/11/1 15:03:03 Last Updated: 2020/11/1 15:54:16

China announced Sunday the full completion of the Three Gorges project, and that it had passed all tests. The dam and reservoir are running smoothly and fully operational in flood control, power generation, navigation and water resources utilization, a sharp rebuke to long-held Western hype and suspicions that it is at risk of collapse and poses a danger to the environment.

The Three Gorges Project is by far the world's largest water control project and the most comprehensive hydropower project, Chinese officials from the Ministry of Water Resources and National Development and Reform Commission announced on Sunday.

Monitoring shows that the river dam, flood discharge, energy dissipation, water diversion and power generation, navigation facilities and protective buildings are in normal operating condition. The mechanical and electrical systems and equipment, and metal structure equipment are also operating safely and stably, they said.

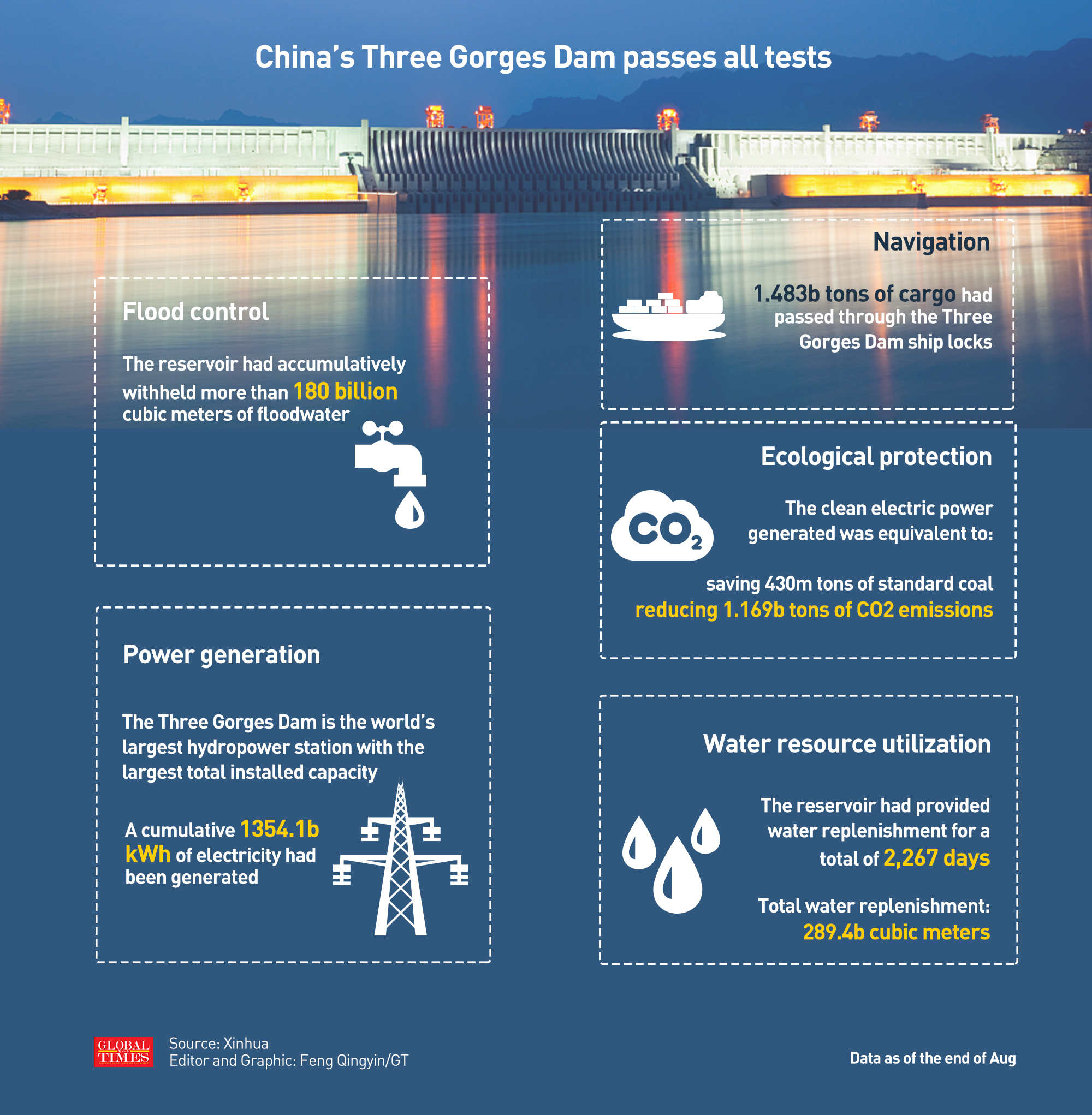

Infographic:GT

In terms of flood control, by the end of August, the Three Gorges Reservoir had accumulated more than 180 billion cubic meters of floodwater. In 2010, 2012 and 2020, the maximum flood peak exceeded 70,000 cubic meters per second. Through the retention by the reservoir, the flood peak was reduced by about 40 percent, greatly reducing the flood control pressure in the middle and lower reaches of the Yangtze River.

The Three Gorges Power Station is also the world's largest hydropower station with the largest total installed capacity. By the end of August, the Three Gorges Power Station had generated 1.354 trillion kilowatt-hours of electricity, boosting power supply in East China, Central China and South China's Guangdong Province and other regions. The reservoir has also become an important large-scale clean energy production base in China.

The project has significantly improved the navigation conditions of the Sichuan River waterway. Since trial navigation in June 2003, the freight volume of the Three Gorges Dam ship locks has increased rapidly, exceeding 100 million tons for the first time in 2011 and reaching 146 million tons in 2019. By the end of August, a total of 1.483 billion tons of cargo had passed through the sluice, giving a strong boost to the development of the Yangtze River Economic Belt.

Photo taken on Aug. 19, 2020 shows water gushing out from the Three Gorges Dam in central China's Hubei Province. Photo: Xinhua

The annual discharge of the Three Gorges Reservoir during the dry season has been raised to more than 5,500 cubic meters per second, bringing replenishment of more than 20 billion cubic meters of water for the middle and lower reaches of the Yangtze River.

By the end of August, the reservoir had provided replenishment for a total of 2,267 days, with a total water supply of 289.4 billion cubic meters, improving the production, living and ecological water conditions in the middle and lower reaches of the Yangtze River.

Also by the end of August, the high-quality clean power generated by the Three Gorges Power Station will be equivalent to saving 430 million tons of standard coal and 1.169 billion tons of carbon dioxide emissions, representing significant benefits in energy conservation and emission reduction.

Officials announced that a total of 1.3 million residents had been relocated during the construction of the project, significantly improving their living conditions. The geological environment of the resettlement area as well as the reservoir are generally safe.

Global Times