Researchers at China’s Wuhan University say they have developed a method of creating exceptionally strong alloys at lower temperatures using a malleable metal called gallium..

Chinese scientists say they have found a way to use a self-healing to absorb other materials and create sought-after new that could transform aerospace, medicine and other fields.

The breakthrough could pave the way for the invention of exceptionally hard, stable types of alloy with unprecedented properties and uses, according to the team, led by Fu Lei, a professor with Wuhan University’s College of Chemistry and Molecular Sciences.

Fu told China Science Daily that the simplicity and effectiveness of the scientists’ method – published last week in the peer-reviewed journal Nature – was initially met with scepticism.

“We found this phenomenon two years ago, but it was hard to convince people that just by adding liquid metals, the synthesis process [of alloy materials] could be greatly improved,” he said.

“Even reviewers from Nature found the results ‘unbelievable’ when they first saw the manuscript.”

To address the sceptics, the researchers conducted further experiments and analysis, as well as a more rigorous explanation of the synthesis mechanism and extra theoretical calculations.

Their results prove that metals synthesised by the new method are no different in composition or structure from traditional methods, and without compromising performance, according to the paper.

The breakthrough would make the creation and manufacture of high-entropy alloys (HEAs) – composed of five or more principal metallic elements – easier and more efficient, the researchers said.

Compared to traditional alloy materials, HEAs are more resistant to wear, fatigue and corrosion, giving them significant potential in aerospace, medical equipment, as well as energy conversion and storage.

While their potential benefits have made HEAs a focus for researchers in recent years, the extremely high temperatures needed to achieve synthesis of the alloy materials have remained a barrier to their development.

According to Fu, synthesising high-entropy alloys can be challenging because the different metallic atoms are not necessarily compatible.

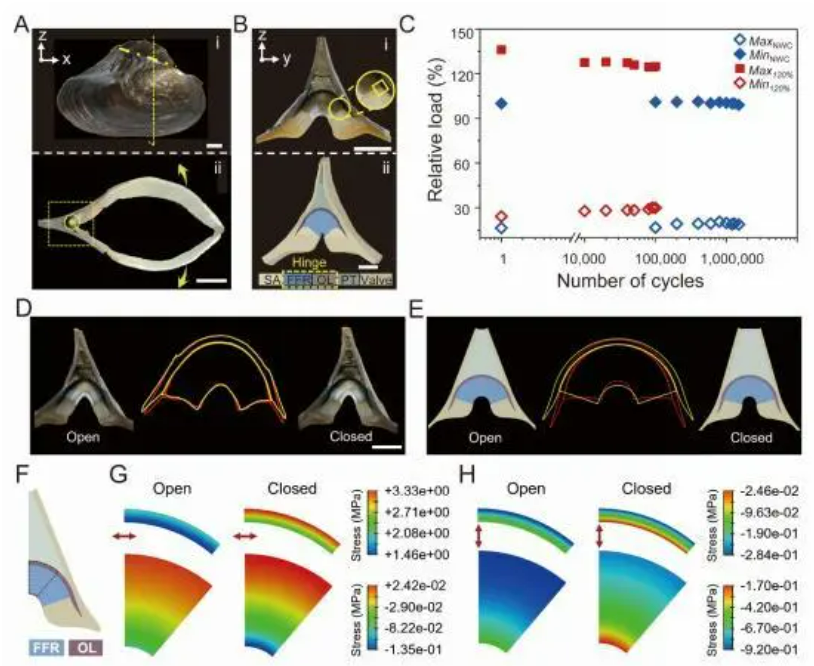

The researchers used energy-dispersive X-ray spectroscopy to map the elements of the alloy during synthesis

“It’s like trying to make a cohesive group out of five people with different natures and personalities. Any disagreements can easily break up the group,” he said.

To achieve synthesis by traditional methods, the alloy materials must be heated to 2,000 degrees Celsius (3,632 Fahrenheit) and then rapidly cooled.

But Fu’s team brought the preparation temperature down to a more manageable 650 Celsius (1,202 Fahrenheit), using a liquid metal called gallium as a reaction medium and adhesive, the paper said.

A schematic of the liquid metal-assisted alloying process

With a low melting temperature of just 29.8 Celsius (85.6 Fahrenheit), gallium will easily turn to liquid in the palm of your hand. It is also highly corrosive to some metals – a single drop can leave a large hole in an aluminium can.

But it is gallium’s ability to return to its original form after being manipulated that has drawn comparisons with the shape-shifting T-1000 killer android of the Terminator film franchise.

Fu’s team found that heating various compatible metals placed on the surface of the liquid metal resulted in the spontaneous growth of crystalline HEA nanoparticles, a process the researchers captured in real time, according to the paper.

The scientists also used gallium to synthesise a diverse range of metal elements into HEAs, something outside the capabilities of traditional methods, which are restricted to palettes of similar elements, according to the paper.

“The involved elements exhibit a broad spectrum of atomic radii (1.24 to 1.97 angstrom) and melting points (303 to 3683 Kelvin),” it said.

According to the researchers, the dynamic mixing reservoir of gallium could be used to synthesise HEAs with a diverse range of metal elements, opening the way for new materials with unique properties and functionalities.

“The in-depth study of the liquid metal reaction mechanism and alloying process has revealed its dynamic evolution process, which also inspires the methodology based on liquid metals.”

China scientists turn to ‘Terminator’ liquid metal in alloy breakthrough

- ‘Unbelievable’ method just adds gallium and it could lead to unprecedented new alloys, researchers said

- The element acts as a dynamic mixing reservoir for metals while its low melting point makes it easier to use, according to paper

Chinese scientists say they have found a way to use a self-healing to absorb other materials and create sought-after new that could transform aerospace, medicine and other fields.

The breakthrough could pave the way for the invention of exceptionally hard, stable types of alloy with unprecedented properties and uses, according to the team, led by Fu Lei, a professor with Wuhan University’s College of Chemistry and Molecular Sciences.

Fu told China Science Daily that the simplicity and effectiveness of the scientists’ method – published last week in the peer-reviewed journal Nature – was initially met with scepticism.

“We found this phenomenon two years ago, but it was hard to convince people that just by adding liquid metals, the synthesis process [of alloy materials] could be greatly improved,” he said.

“Even reviewers from Nature found the results ‘unbelievable’ when they first saw the manuscript.”

To address the sceptics, the researchers conducted further experiments and analysis, as well as a more rigorous explanation of the synthesis mechanism and extra theoretical calculations.

Their results prove that metals synthesised by the new method are no different in composition or structure from traditional methods, and without compromising performance, according to the paper.

The breakthrough would make the creation and manufacture of high-entropy alloys (HEAs) – composed of five or more principal metallic elements – easier and more efficient, the researchers said.

Compared to traditional alloy materials, HEAs are more resistant to wear, fatigue and corrosion, giving them significant potential in aerospace, medical equipment, as well as energy conversion and storage.

While their potential benefits have made HEAs a focus for researchers in recent years, the extremely high temperatures needed to achieve synthesis of the alloy materials have remained a barrier to their development.

According to Fu, synthesising high-entropy alloys can be challenging because the different metallic atoms are not necessarily compatible.

The researchers used energy-dispersive X-ray spectroscopy to map the elements of the alloy during synthesis

“It’s like trying to make a cohesive group out of five people with different natures and personalities. Any disagreements can easily break up the group,” he said.

To achieve synthesis by traditional methods, the alloy materials must be heated to 2,000 degrees Celsius (3,632 Fahrenheit) and then rapidly cooled.

But Fu’s team brought the preparation temperature down to a more manageable 650 Celsius (1,202 Fahrenheit), using a liquid metal called gallium as a reaction medium and adhesive, the paper said.

A schematic of the liquid metal-assisted alloying process

With a low melting temperature of just 29.8 Celsius (85.6 Fahrenheit), gallium will easily turn to liquid in the palm of your hand. It is also highly corrosive to some metals – a single drop can leave a large hole in an aluminium can.

But it is gallium’s ability to return to its original form after being manipulated that has drawn comparisons with the shape-shifting T-1000 killer android of the Terminator film franchise.

Fu’s team found that heating various compatible metals placed on the surface of the liquid metal resulted in the spontaneous growth of crystalline HEA nanoparticles, a process the researchers captured in real time, according to the paper.

The scientists also used gallium to synthesise a diverse range of metal elements into HEAs, something outside the capabilities of traditional methods, which are restricted to palettes of similar elements, according to the paper.

“The involved elements exhibit a broad spectrum of atomic radii (1.24 to 1.97 angstrom) and melting points (303 to 3683 Kelvin),” it said.

According to the researchers, the dynamic mixing reservoir of gallium could be used to synthesise HEAs with a diverse range of metal elements, opening the way for new materials with unique properties and functionalities.

“The in-depth study of the liquid metal reaction mechanism and alloying process has revealed its dynamic evolution process, which also inspires the methodology based on liquid metals.”