Regardless misunderstanding or not, I have explained the difference between what F-22 uses and what CCTV presented. That should be enough to clarify things.I'm pretty sure there's a misunderstanding, in that what's used in radomes is by now quite common and presumably not the same thing being hinted at in the CCTV report. If that's so, there's not much to clear up.

(Disclaimer: this comment made without any technical knowledge.)

Just out of curiosity, what does the "" qualify as?

About fiber mat, here I quote the link.

But during development, something happened. First, program officials began hinting the F-35 might be stealthier than the F-22; hard to believe, given its less-disciplined shape. Then officials started referring to a material secret, a “conductive layer . . . where the magic happens.” In May of 2010, Tom Burbage, then executive vice president for the F-35 program, disclosed the incorporation of “fiber mat” technology, describing it as the “biggest technical breakthrough we’ve had on this program.”

The fiber mat would replace many RAM appliques by being cured into the composite skin, making it durable. Burbage further specified the mat featured a “non-directional weave”— which would ensure EM properties do not vary with angle. Baked into the skin, this layer could vary in thickness as necessary. Lockheed declined to provide further details, citing classification. Without further evidence, fiber mat would imply use of fibers, rather than particles, which would make for stronger surfaces and the word “conductive” points to carbon-based RAM.

But only a month before Burbage’s disclosure, Lockheed filed a patent claiming the first method of producing a durable RAM panel. The patent details a method for growing carbon nanotubes (CNT) on any kind of fiber—glass, carbon, ceramic or metal—with unprecedented precision in control of length, density, number of walls, connectivity and even orientation. The CNT-infused fibers can absorb or reflect radar, and connectivity among the CNTs provides pathways for induced currents.

Significantly, the CNTs can be impregnated with iron or ferrite nanoparticles. Fibers can have differing CNT densities along their lengths and homogenous fibers can be layered or mixed. The embodiments described include front layers with impedance matching air, use of quarter-wavelength depths for cancellation, stepped or continuous CNT-density gradients and continuously varying densities at specific depths for broadband absorption. The fibers can be disposed with “random orientation” in materials including “a woven fabric, a non-woven fiber mat and a fiber ply.”

The patent claims composites with CNT-infused fibers are capable of absorbing EM waves from 0.1 MHz to 60 GHz, a bandwidth unheard of in commercial absorbers, with particular effectiveness in L- through K-band. The patent does not quantify the absorptivity, but does say the panels would be “nearly a black body across . . . various radar bands.” Also, interestingly, a layer can be composed so an attached computer can read the induced currents in the fibers, making the layer a radar receiver.

While the patent mentions stealth aircraft, it does not mention the F-35 specifically, and the manufacturing readiness level of the material at the time it was granted is not known. But the proximity in timing and technology of the filing to the “fiber mat” disclosure is hard to ignore. Asked to comment on whether CNT-infused fiber RAM is in use on the F-35 and whether it is the technology to which Burbage had referred, Lockheed Martin spokesman Mike Rein stated only, “We have nothing to add to what was outlined in the patent submittal.”

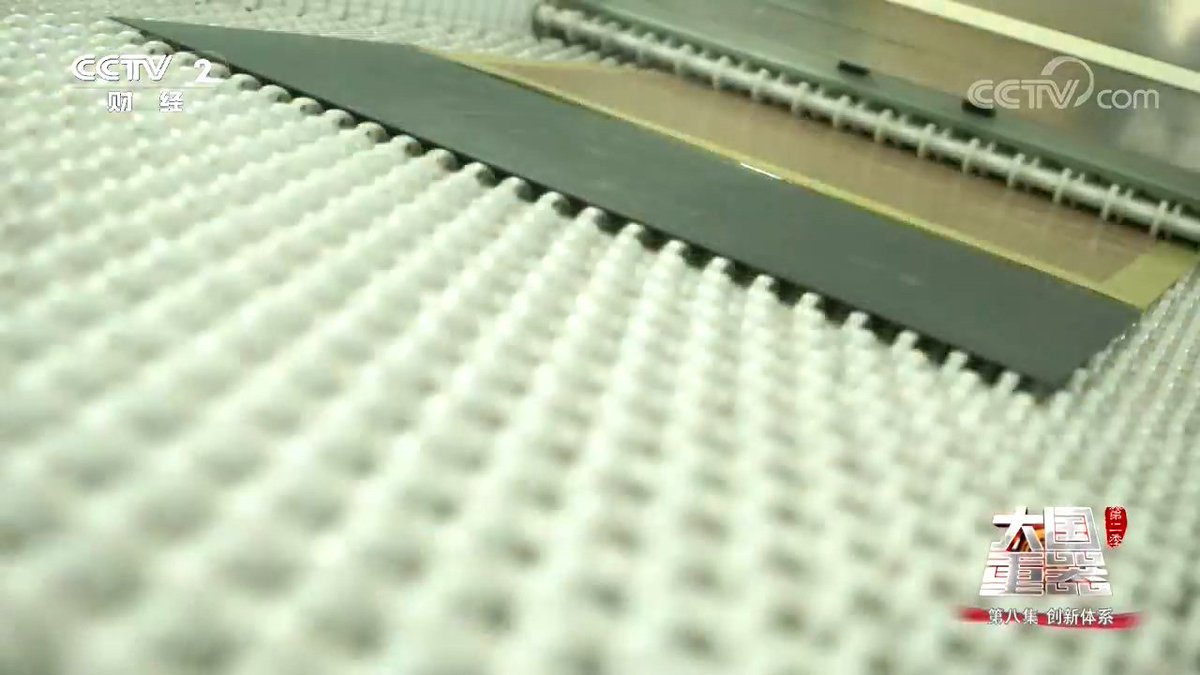

It seems to be weaving conductive fibers (CNT infused) in composite material. It is another approach but different from what CCTV presented. The bold texts above indicate something in the same vain as patterns in the metamaterial. They try to reach the same goal. The main difference as I see is easiness of making the desired pattern, steps of density gradients. In China's case, the pattern is printed on the substrate, in LM's patent, the steps of density are achieved by controlling things such as force (therefor the stress) of laying fibers one layer above another, the thickness of each layers. Without knowing more than the patent's words, I would prefer the China approach as being easier to achieve.

I think Plawolf's post #2089 is a good comment. It is traditional fabrication procedure vs. recent developed fabrication procedures. Inter-breeding vs. genetic engineering (without natural breeding). Forging/Casting/Milling vs. 3D printing.