Fourth generation of semiconductor lighting technology ..

South China University of Technology has made new progress in research on high-power near-infrared light sources..

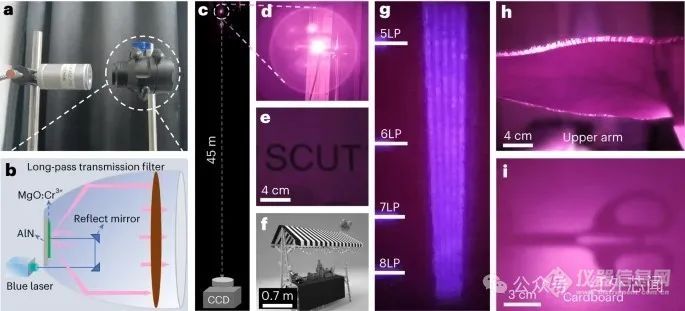

Introduction: Using an extremely simple MgO:Cr³⁺ near-infrared fluorescent transparent ceramic, a blue laser-driven near-infrared light source device was produced. The output power reached the current record high of 6 W, and its use in long-distance night vision supplementary light and Applications in non-destructive testing imaging and other fields.

Recently, Professor Xia Zhiguo's team from the State Key Laboratory of Luminescent Materials and Devices of South China University of Technology published a research paper titled "Laser-Driven BroadbandNear-Infrared Light Source with Watt-Level Output" online in the journal Nature Photonics . The paper reports on an extremely simple MgO:Cr³⁺ near-infrared fluorescent transparent ceramic. The output power of the blue laser-driven near-infrared light source device produced reached the current record high of 6 W, and demonstrated its long-distance night vision supplementation. Applications in areas such as light and non-destructive testing imaging.

Blue light-emitting diodes (LEDs) have given birth to the fourth generation of semiconductor lighting technology. New application requirements have put forward higher requirements for light source devices. Blue-light laser diodes (LDs) combined with fluorescent conversion materials have become an important development direction. It is made of extremely bright blue LD-pumped fluorescent conversion materials and has great potential in applications such as aviation and navigation lighting, underwater lighting, laser fluorescent display projectors, and high-power near-infrared light source devices.

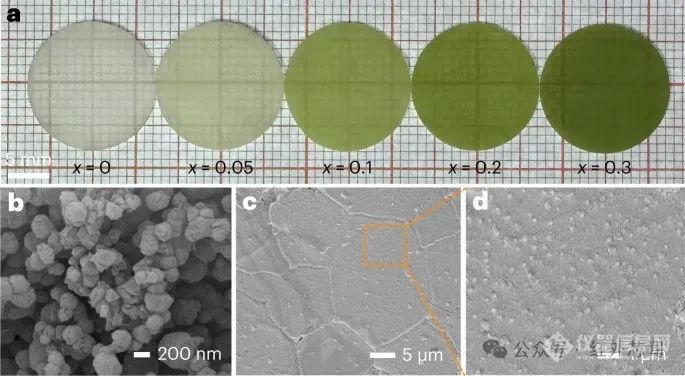

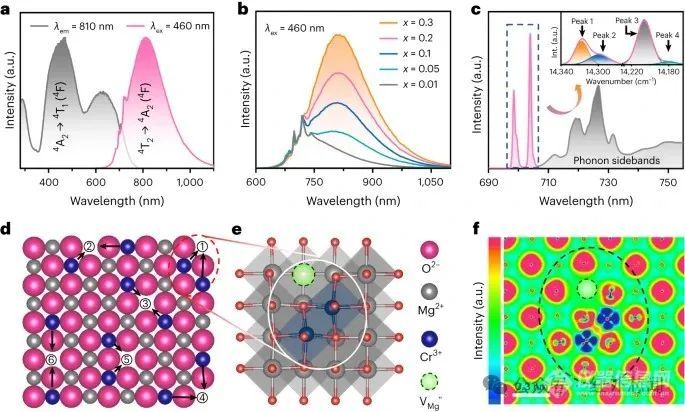

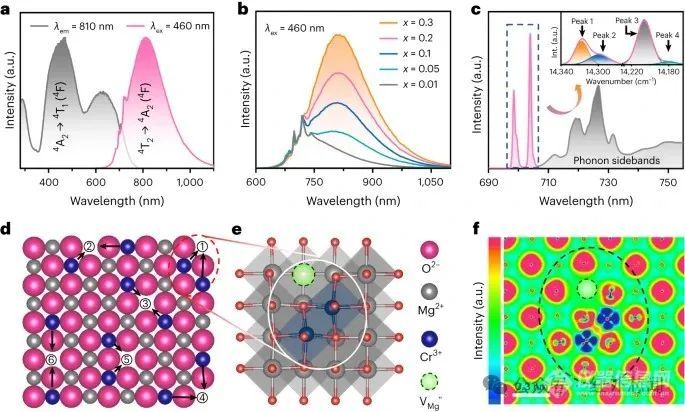

This research invented a highly stable MgO:Cr³⁺ fluorescent transparent ceramic that is close to "perfect performance" (Chinese invention patent, ZL202211147958.4). Its broadband near-infrared luminescence emission peak is 810 nm, achieving the highest external performance to date. Quantum efficiency (81%). The Cr³⁺ ions introduced through doping are heterovalently substituted at the Mg²⁺ lattice site, resulting in abundant cation vacancy defects in the structure, forming Cr³⁺ luminescence centers with different local environments. At the same time, the phonons between the luminescent centers assist the excited state energy transfer process, which compensates for the non-radiative relaxation of long-wavelength emission, overcomes the influence of energy gap ratio, and improves the luminous efficiency. Further benefiting from the ultra-high thermal conductivity of MgO fluorescent transparent ceramics, a broadband near-infrared output power of more than 6 W was obtained under 22 W/mm² blue LD pumping, with a light conversion efficiency of 29%.

The prototype device built using this technology can penetrate 3 cm thick opaque cardboard and achieve imaging of the scissors model, with an imaging resolution of 6l p/mm. This new laser-driven high-power near-infrared light source has broad application prospects in the fields of night vision supplementary light, industrial flaw detection equipment, and non-destructive testing imaging of medical devices.