@tokenanalyst bro from your previous post and with @foofy , China seems had the testing and packaging processes all sewed up, we're only lacking in DUVL (check finally solved) and EUVL plus the masking part materials and industrial gases?Hikvision: Hikvision Micro-Photography has built an 8-inch MEMS production line and packaging line

Haikang Micro-Photography also has a total of 20 complete machine production lines covering an area of 10,000 square meters, with a maximum annual output of 1.5 million units. The manufacturing and testing are strictly in accordance with high-quality production requirements. The materials are tested by multiple standards and carefully selected; production The process is strictly controlled, the core components are fully automated, and the dust-free clean room is packaged; the products have undergone multiple strict tests such as aging and air tightness before leaving the factory to ensure that the products are stable and reliable.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese semiconductor industry

- Thread starter Hendrik_2000

- Start date

- Status

- Not open for further replies.

Geely is planning on making a 7nm SOC chip. Anyone know how it's going to be done with sanctions in place?

Chinese carmaker Geely Automobile Holdings is preparing to plough CNY150 billion (USD23.4 billion) into research and development over the next four years

Is geely on the entity list?Geely is planning on making a 7nm SOC chip. Anyone know how it's going to be done with sanctions in place?

The article talks about 2023 for 7nm maybe by then domestic DUVL might have enough capacity or maybe they will vertically integrate like BYD.

Hendrik_2000

Lieutenant General

Via vincent write up on the new lens patent disclosure of SMEE

A patent filed by SMEE in 2018 showed SMEE's lens design for lithography equipment reduces processing manufacturing cost, increases numerical aperture, can be used for GHI three-wire band, increases the number of use cases for the projection system, improves the resolution of the projection.

Source: Aijiwei

# Patent decryption#

10-24 13:36

【Jiaqin Comment】Shanghai Microelectronics' patent for lithography projection objective lens, through the use of spherical lens design, reduces the manufacturing cost, increases the numerical aperture, and is suitable for the ghi three-line band. The applicable scene of the projection objective is expanded, and the resolution of the lithography machine is improved.

According to news from Jiwei, Shanghai Microelectronics recently held a new product launch conference and announced the launch of a new generation of large-field high-resolution advanced packaging lithography machines. At present, Shanghai Microelectronics has reached a sales agreement with a number of customers for a new generation of advanced packaging lithography machines, and the first one will be delivered within this year.

Optical lithography is a technology that uses light to project and copy mask patterns. The integrated circuit is made by a projection exposure device to image patterns with different mask patterns on the substrate to manufacture integrated circuits, thin-film magnetic heads, and liquid crystal displays. A series of structures such as boards, or micro-electromechanical systems. In the past few decades, the technology level of exposure equipment has been continuously developed to meet the needs of smaller line size, larger exposure area, higher reliability and productivity, and lower cost. However, the existing lithographic projection objective lenses still have problems such as small numerical aperture, low resolution, narrow applicable wavelength band, invariable numerical aperture, and high manufacturing cost of aspheric lenses.

To this end, Shanghai Microelectronics applied for an invention patent entitled "A lithographic projection objective and lithography machine" on December 30, 2018 (application number: 201811648523.1), and the applicant is Shanghai Microelectronics Equipment (Group) Company limited by shares.

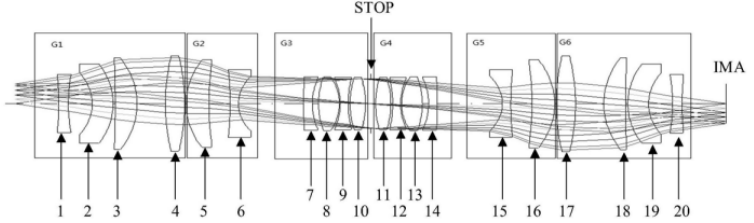

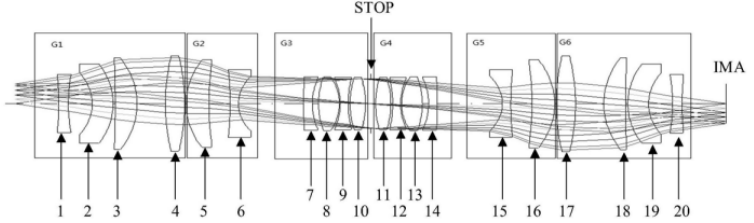

Figure 1 Schematic diagram of lithography projection objective lens structure

1 is a schematic diagram of the structure of the lithographic projection objective proposed by the present invention, including a first lens group, a second lens group, and a third lens group, as well as a fourth lens group and a fifth lens arranged symmetrically with the above lens group about the aperture Group and sixth lens group. By adjusting the size of the aperture of the diaphragm, the numerical aperture of the lithography projection objective lens can be adjusted, thereby increasing the ability of the lithography projection objective lens to be suitable for different scenes. In addition, the focal length setting of each lens group can increase the numerical aperture of the lithography projection objective lens, and improve the resolution of the lithography projection objective lens.

The first lens group G1, the third lens group G3, the fourth lens group G4, and the sixth lens group G6 have positive refractive power, and the second lens group G2 and the fifth lens group G5 have negative refractive power. The optical power is equal to the difference between the image-side beam convergence and the object-side beam convergence, and it represents the ability of the optical system to deflect light. The greater the absolute value of the optical power, the stronger the bending ability to light, and the weaker the bending ability to light. When the refractive power is positive, the refraction of the light is convergent, otherwise it is divergent. The optical power can be used to characterize a certain refractive surface of a lens, or to characterize a certain lens, or it can be used to characterize a system formed by multiple lenses.

Each lens group and all lenses in the stop STOP are spherical lenses. Spherical lens refers to the constant curvature from the center to the edge of the lens. The two refractive surfaces of the spherical lens are spherical, while the curvature of the aspheric lens changes continuously from the center to the edge. Therefore, the spherical lens is relative to the aspheric lens. In terms of easier processing. The lenses in the embodiments of the present invention all adopt spherical lenses, which reduces the processing cost of the lens in the lithographic projection objective, shortens the processing period of the lens, and improves the assembly and adjustment efficiency of the lithographic projection objective.

In short, Shanghai Microelectronics' lithography projection objective lens patent, through the use of spherical lens design, reduces the processing and manufacturing costs, increases the numerical aperture, and is suitable for the ghi three-line band. The applicable scene of the projection objective is expanded, and the resolution of the lithography machine is improved.

Shanghai Microelectronics is committed to the R&D and production of high-end projection lithography machines for the semiconductor industry. With the ultimate service, high-end products are created, creating outstanding value, and providing customers with high-quality products and technical services all-weather, all-round and wholeheartedly. Facing the future, Shanghai Microelectronics will strive to grasp the historical opportunity of the rapid development of China's semiconductor industry.

About

Shenzhen Jiaqin Intellectual Property Agency Co., Ltd. is composed of intellectual property experts, lawyers, and patent agents who have worked for Huawei and other Fortune 500 companies for many years. He has rich experience in litigation, license negotiation, transaction, operation, standard patent co-creation, patent pool construction, exhibition intellectual property, cross-border e-commerce intellectual property, intellectual property customs protection, etc.

A patent filed by SMEE in 2018 showed SMEE's lens design for lithography equipment reduces processing manufacturing cost, increases numerical aperture, can be used for GHI three-wire band, increases the number of use cases for the projection system, improves the resolution of the projection.

Decrypt Shanghai Microelectronics New Type Lithography Machine Black Technology

Source: Aijiwei

# Patent decryption#

10-24 13:36

【Jiaqin Comment】Shanghai Microelectronics' patent for lithography projection objective lens, through the use of spherical lens design, reduces the manufacturing cost, increases the numerical aperture, and is suitable for the ghi three-line band. The applicable scene of the projection objective is expanded, and the resolution of the lithography machine is improved.

According to news from Jiwei, Shanghai Microelectronics recently held a new product launch conference and announced the launch of a new generation of large-field high-resolution advanced packaging lithography machines. At present, Shanghai Microelectronics has reached a sales agreement with a number of customers for a new generation of advanced packaging lithography machines, and the first one will be delivered within this year.

Optical lithography is a technology that uses light to project and copy mask patterns. The integrated circuit is made by a projection exposure device to image patterns with different mask patterns on the substrate to manufacture integrated circuits, thin-film magnetic heads, and liquid crystal displays. A series of structures such as boards, or micro-electromechanical systems. In the past few decades, the technology level of exposure equipment has been continuously developed to meet the needs of smaller line size, larger exposure area, higher reliability and productivity, and lower cost. However, the existing lithographic projection objective lenses still have problems such as small numerical aperture, low resolution, narrow applicable wavelength band, invariable numerical aperture, and high manufacturing cost of aspheric lenses.

To this end, Shanghai Microelectronics applied for an invention patent entitled "A lithographic projection objective and lithography machine" on December 30, 2018 (application number: 201811648523.1), and the applicant is Shanghai Microelectronics Equipment (Group) Company limited by shares.

Figure 1 Schematic diagram of lithography projection objective lens structure

1 is a schematic diagram of the structure of the lithographic projection objective proposed by the present invention, including a first lens group, a second lens group, and a third lens group, as well as a fourth lens group and a fifth lens arranged symmetrically with the above lens group about the aperture Group and sixth lens group. By adjusting the size of the aperture of the diaphragm, the numerical aperture of the lithography projection objective lens can be adjusted, thereby increasing the ability of the lithography projection objective lens to be suitable for different scenes. In addition, the focal length setting of each lens group can increase the numerical aperture of the lithography projection objective lens, and improve the resolution of the lithography projection objective lens.

The first lens group G1, the third lens group G3, the fourth lens group G4, and the sixth lens group G6 have positive refractive power, and the second lens group G2 and the fifth lens group G5 have negative refractive power. The optical power is equal to the difference between the image-side beam convergence and the object-side beam convergence, and it represents the ability of the optical system to deflect light. The greater the absolute value of the optical power, the stronger the bending ability to light, and the weaker the bending ability to light. When the refractive power is positive, the refraction of the light is convergent, otherwise it is divergent. The optical power can be used to characterize a certain refractive surface of a lens, or to characterize a certain lens, or it can be used to characterize a system formed by multiple lenses.

Each lens group and all lenses in the stop STOP are spherical lenses. Spherical lens refers to the constant curvature from the center to the edge of the lens. The two refractive surfaces of the spherical lens are spherical, while the curvature of the aspheric lens changes continuously from the center to the edge. Therefore, the spherical lens is relative to the aspheric lens. In terms of easier processing. The lenses in the embodiments of the present invention all adopt spherical lenses, which reduces the processing cost of the lens in the lithographic projection objective, shortens the processing period of the lens, and improves the assembly and adjustment efficiency of the lithographic projection objective.

In short, Shanghai Microelectronics' lithography projection objective lens patent, through the use of spherical lens design, reduces the processing and manufacturing costs, increases the numerical aperture, and is suitable for the ghi three-line band. The applicable scene of the projection objective is expanded, and the resolution of the lithography machine is improved.

Shanghai Microelectronics is committed to the R&D and production of high-end projection lithography machines for the semiconductor industry. With the ultimate service, high-end products are created, creating outstanding value, and providing customers with high-quality products and technical services all-weather, all-round and wholeheartedly. Facing the future, Shanghai Microelectronics will strive to grasp the historical opportunity of the rapid development of China's semiconductor industry.

About

Shenzhen Jiaqin Intellectual Property Agency Co., Ltd. is composed of intellectual property experts, lawyers, and patent agents who have worked for Huawei and other Fortune 500 companies for many years. He has rich experience in litigation, license negotiation, transaction, operation, standard patent co-creation, patent pool construction, exhibition intellectual property, cross-border e-commerce intellectual property, intellectual property customs protection, etc.

I think that apart from continuing to investing in duvl and euvl, is also good that they continue to invest in packaging because I believe that we are going to have two more moore's law, one in packaging, integrating as many dies in a single package as possible in novel architectures in the most integrated way possible, like chiplets, 2.5d Heterogeneous, 3d stacking and so on. And the other would be with new materials such as silicon carbide and gallium nitride, manufacturing integrated circuits with these new materials for new applications like electric cars.@tokenanalyst bro from your previous post and with @foofy , China seems had the testing and packaging processes all sewed up, we're only lacking in DUVL (check finally solved) and EUVL plus the masking part materials and industrial gases?

Investing in this new technologies along side with DUVL and EUVL i think will allow China to sidestep sanctions and be at the forefront at the same time.

I recently heard an unconfirmed report from a WeChat group that Guangdong wants to invest RMB150bn in 14nm chip fabs, but that they'll cooperate with Huawei... Does this make sense to anyone? That's enough money to set up several fabs with cumulative output of about 250k~ 14nm 12" wafers/month, and it seems strange that it would be with Huawei and not Shanghai Huali or SMIC.

antiterror13

Brigadier

I recently heard an unconfirmed report from a WeChat group that Guangdong wants to invest RMB150bn in 14nm chip fabs, but that they'll cooperate with Huawei... Does this make sense to anyone? That's enough money to set up several fabs with cumulative output of about 250k~ 14nm 12" wafers/month, and it seems strange that it would be with Huawei and not Shanghai Huali or SMIC.

Perhaps to make sure that there is certain buyer to buy the products (Huawei), also Huawei is giant in technology

Makes sense Huawei might be the big customers needed to recoup the costs, also before the Huawei TSMC ban Huawei was one of their biggest customer of the high end nodes. So it might make sense to develop together with Huawei this high tech fab.Perhaps to make sure that there is certain buyer to buy the products (Huawei), also Huawei is giant in technology

With all these new investments, Guangdong province will be bigger than Korea in semiconductors.I recently heard an unconfirmed report from a WeChat group that Guangdong wants to invest RMB150bn in 14nm chip fabs, but that they'll cooperate with Huawei... Does this make sense to anyone? That's enough money to set up several fabs with cumulative output of about 250k~ 14nm 12" wafers/month, and it seems strange that it would be with Huawei and not Shanghai Huali or SMIC.

- Status

- Not open for further replies.