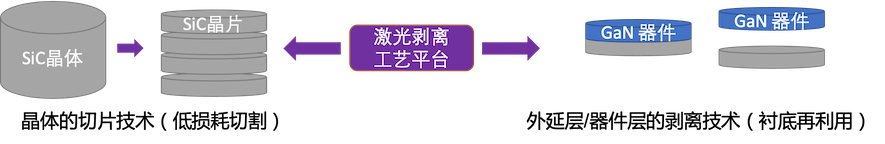

AMEC is expanding into all areas of semiconductor production, not just logic, DRAM, etc. this means that they're doing analog, power, RF, LED, etc. I also believe in this paper, they're demoing their MOCVD production tools, which is something new as they're best known for etching.

Its a short step from MOCVD to ALD. That means AMEC is rapidly expanding its technical offering and becoming more like NAURA, rather than only etch focused semiconductor company. There's many 1 sector companies, but much harder to become something like LAM, AMAT or TEL.

I think also point out the modern collaborative approach between the Chinese semiconductor industry and research institutions in designing the manufacturing process of different devices, that means that Chinese equipment is probably going to become the standard for the manufacturing of these devices in the future.

This kind of industry-academy collaboration was less common in the past and more common today. US companies benefited from this approach as semiconductor fab companies collaborated with Chinese academia and US toolmakers to design their process around US tools, that is why when US companies pull out was bad because a lot of the process where designed around US made tools.

So in the future is probably that we are going to see less or any collaboration in process design with US tool companies and more collaboration with Chinese tool companies

Last edited: