The problem with EUV is the extreme accuracy that everything has to be done, this is from the research that has been made in CIOMPActually, I think EUVL is easier than the space station.

Shortwave Optics - Extremely Fine

The uproar of the "ZTE Incident" has brought people's attention to the key components of the "chip", which seems to be inconspicuous but affects the whole body. A series of high-end equipment involved in chip preparation has become more and more important, and the most important of these is the lithography machine. The lithography projection objective is one of the core components of the lithography machine, and its design and manufacture represent the highest level of contemporary precision optics and precision machinery.

The difficulty of lithography objectives is concentrated in two words - "precision" .

Taking the EUV lithography objective lens as an example, its optical system consists of 6 aspherical mirrors the size of a pot cover. These mirrors have extremely stringent surface shape accuracy requirements, coating requirements and support requirements. Give a few examples to see what kind of extreme precision is achieved!

l The surface shape of the reflector requires that the fluctuation degree of the surface should be much less than one nanometer, which is equivalent to that the fluctuation cannot exceed 0.5mm on such a large area in Jilin Province ;

l In addition, dozens or even hundreds of ultra-thin films should be coated on such a flat surface, and the surface shape error after coating is also better than 1 nanometer, which is equivalent to a uniform surface on such a large area in Jilin Province. Spread a sheet of thousand-layer cake, and the thickness deviation of the cake should be less than 0.5mm ;

l The tilt adjustment control between the mirrors should be at the sub-nanometer radian level, which is equivalent to controlling a beam of light directed at the moon 380 million meters away, and accurately positioning the beam on the moon within 10 centimeters.

Therefore, the design and manufacture of the lithographic projection objective represents the highest level of precision optics and precision machinery in equipment manufacturing, and is the most sophisticated and complex optical system that can be developed by human beings at present.

In June 2017 , the "Key Technology Research of Extreme Ultraviolet Lithography" undertaken by the State Key Laboratory of Applied Optics successfully passed the preliminary acceptance, and obtained EUV projection lithography 32nm exposure pattern for the first time in China, laying a solid foundation for China to truly master high-end microelectronics manufacturing technology. foundation.

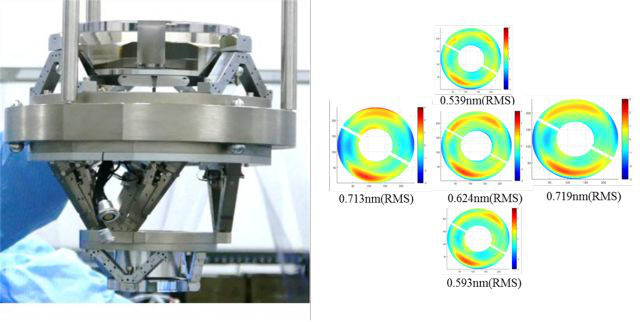

Fig. 3 EUV lithography objective (image source: research group) Fig. 4 Wave aberration distribution diagram of projection objective lens system (image source: research group)

As you can see the precision needed is just extreme. Another example is from the research in the Shanghai institute of fine optics and mechanics SIOM.

Representative results:

1. The extreme ultraviolet lithography wave aberration detection system developed as the technical leader has a 48 -hour wavefront long-term measurement repeatability of 0.1nmRMS , and a 38 -day wavefront long -term test repeatability of 0.24nmRMS .

The precision of that instrument reached 0.1nm, that is like measuring an hydrogen atom for 48 hours and a silicon atom for a month without fail. The Chinese has done a great job but the task of developing such systems should not be underestimated whatever is LPP or SSMB, this are physics to the extreme.