[ANALYSIS] Yield troubles at Samsung Electronics endanger big bets

A Samsung Electronics employee inspects chip equipment at the company's plant in Hwaseong, Gyeonggi. [JOONGANG PHOTO]

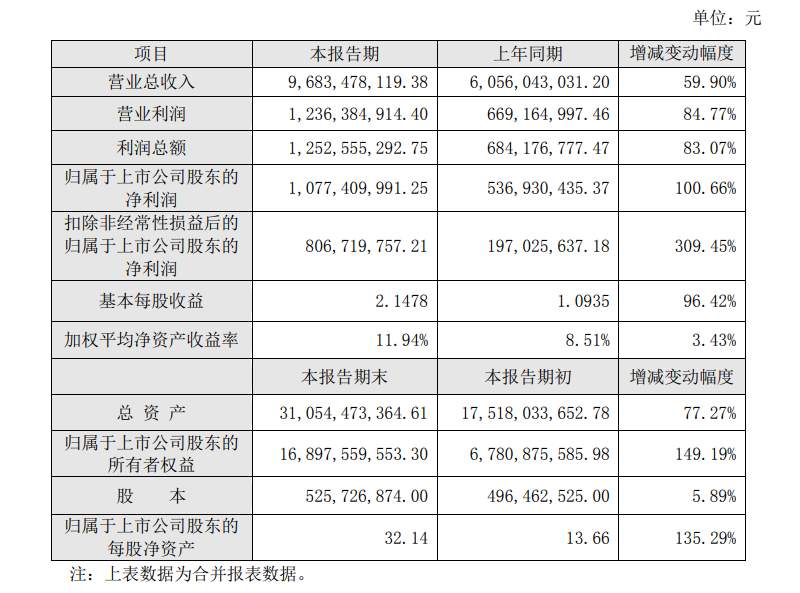

Samsung Electronics is struggling with semiconductor yield problems that endanger its big bets on systems chips and the foundry business.

The problem, which has been evident for some time and a favorite topic of the semiconductor trade press, went prime time with the roll out of the latest Exynos, a system chip developed by Samsung Electronics that is supposed to compete with Qualcomm's Snapdragon line and allow the company, the largest smartphone maker in the world, to match the performance Apple products.

"Samsung Electronics encountered trouble ramping up production yields of 4-nanometer chips as shown in the delay of its Exynos 2200 delivery," said Jeong In-seong, a semiconductor specialist who authored "The Future of the Semiconductor Empire."

"Samsung Electronics had to trim down the number of countries where Exynos-powered Galaxy S22 models retail because of the yield issue. It shipped them to only a handful of small markets in Europe," he said. In the company's major smartphone markets — the United States, Korea and India — all Galaxy S22s had Snapdragon processors.

The yield rate is the amount of a silicon wafer that is successfully made into dies, which are themselves packaged to become semiconductors. The lower the yields, the less product produced.

Samsung Electronics would not confirm the actual yields of its 4-nanometer chips, but media reports in Korea put the rate at between 20 percent and 30 percent. TSMC reported yields of around 80 percent for its 5-nanometer products in 2019.

Against this backdrop, Samsung Electronics recently initiated an internal probe into its foundry, or chip fabrication, business division. These probes are usually undertaken to look more closely into the operations of poorly-performing units, though a Samsung Electronics spokesperson said that in this case it is just "a regular event to enhance competitiveness."

It is the first time for the foundry business, which was made a separate division in 2017, to be the subject of such a probe.

Kang Moon-soo, head of the foundry market strategy team at Samsung Electronics, acknowledged the difficulties producing chips based on the latest manufacturing techniques during a conference call in January.

"It is true that we have trouble achieving a stabilized yield rate in the beginning stage" of adopting the new manufacturing process, Kang said, citing the complexity of the fabrication process.

Keeping with Moore's Law by dimensional scaling alone just keep getting harder.

![A Samsung Electronics employee inspects chip equipment at the company's plant in Hwaseong, Gyeonggi. [JOONGANG PHOTO] A Samsung Electronics employee inspects chip equipment at the company's plant in Hwaseong, Gyeonggi. [JOONGANG PHOTO]](https://koreajoongangdaily.joins.com/data/photo/2022/03/14/ec7f54ba-2563-4d73-8042-8e32c71bc0fc.jpg)