Another one from @Oldschool ,he and I speculate that it may used Local Equipment.

Today at 3:07 PMNew

I am curious what type of equipments they use for manufacturing.

It's not a standard CMOS process and the news said it used self developed equipments.

Oldschool

Junior Member

Registered MemberToday at 3:07 PMNew

I am curious what type of equipments they use for manufacturing.

It's not a standard CMOS process and the news said it used self developed equipments.

原文来源:杭州日报记者:管光前 叶佳裕 通讯员:刘方泽 周艳清虎年新春伊始,杭州青山湖科技城传来佳音。由昕原半导体(杭州)有限公司(以下称“昕原半导体”)主导建设的大陆首条28/22nm ReRAM(阻变存储器)12...

- It is expected to help the domestic new storage field to achieve "curve overtaking" The first resistive memory pilot test line in mainland China opens in Lin'an!

- Release time: 2022-02-17 17:46 267

- Original source: Hangzhou Daily

Reporter: Guan Guangqian Ye Jiayu Correspondent: Liu Fangze and Zhou Yanqing

At the beginning of the Chinese New Year of the Tiger Year, good news came from Hangzhou Qingshan Lake Science and Technology City. The first 28/22nm ReRAM (resistive variable memory) 12-inch pilot production line in mainland China , led by Xinyuan Semiconductor (Hangzhou) Co., Ltd. (hereinafter referred to as "Xinyuan Semiconductor") , has successfully completed the installation and acceptance of self-developed equipment. The process flow of the pilot line has been connected, and the film has been successfully taped out.

Xinyuan Semiconductor technicians conduct equipment debugging on the pilot line

The new memory "Qianjing" is broad

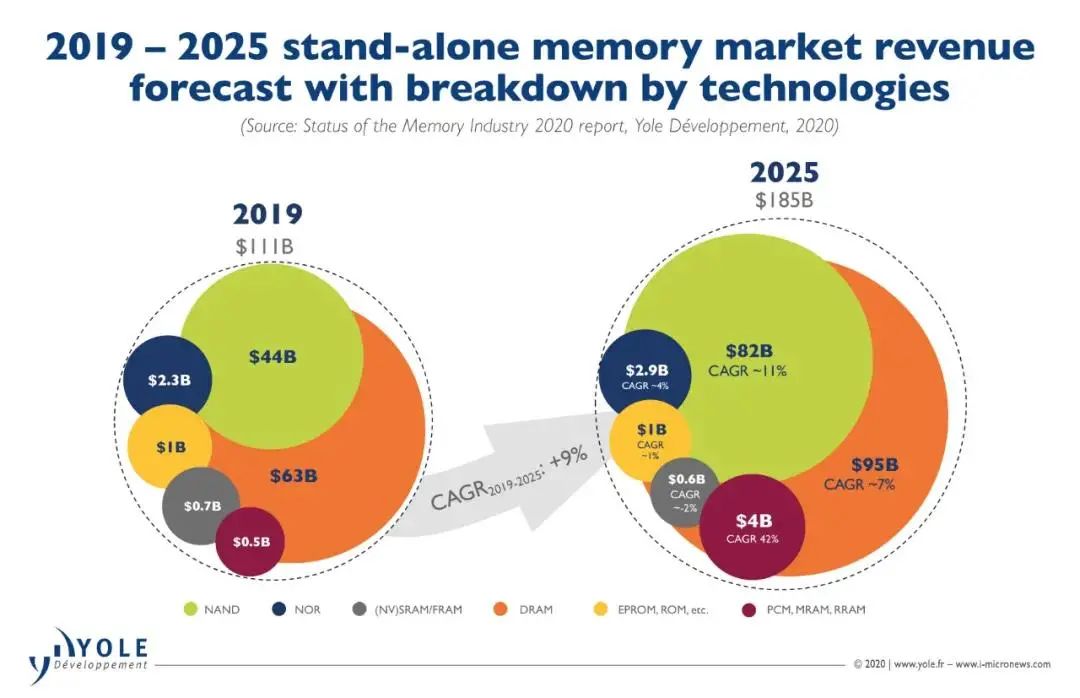

In the national "14th Five-Year Plan" outline, in terms of strengthening original and leading scientific and technological research, "advanced storage technology upgrade" has been included in the key area of "research in frontier areas of science and technology". And according to the statistics of Yole Development, the world's authoritative semiconductor market research organization, the overall memory market space will increase from US$111 billion in 2019 to US$ 185 billion in 2025 .

Global memory market size and growth rate (Source: YOLE)

At present, my country is vigorously developing the storage industry: on the one hand, it is striving to catch up with traditional memory, such as YMTC, which fully invests in NAND Flash (a type of Flash memory) and focuses on DRAM (the most common system memory for dynamic random access memory). On the other hand, it is also laying out new types of memory in advance.

With the advent of the era of the Internet of Everything, in response to the needs of future artificial intelligence (AI), smart cars, artificial intelligence and the Internet of Things (AIOT) and edge computing (Edge Computing) and other high computing capabilities, such as DRAM, NAND and other high-capacity memories. Flash memory's high power consumption and speed issues can no longer keep pace with the times. To put it simply, whether DRAM can be stored (data is lost after power failure), and whether NAND Flash can be stored (low read and write speed), if NAND+DRAM is used together, it will cause high energy consumption, and another common memory is Nor Due to the low storage density (low storage capacity) of Flash and the inability to embed processes below 28nm/22nm, it is difficult to achieve performance breakthroughs on the existing basis.

Under the urgent needs of the market, it is imperative to develop and produce a new generation of memory that integrates high storage density, high speed, low power consumption, and can be embedded in processes below 28nm.

Simple material, low cost, but unusual performance

At present, the world's mainstream new memory technologies mainly include PCM (phase change memory), FeRAM (ferroelectric memory), MRAM (magnetic memory) and ReRAM (resistive change memory) . Compared to several other new memory technologies, ReRAM requires fewer types of materials and the number of additional masks, allowing for lower production costs. At the same time, the industry generally believes that ReRAM can fully meet the energy consumption, performance and storage density requirements of applications such as neuromorphic computing and edge computing, and is expected to be widely used in AIoT, smart cars, data centers, AI computing (integration of storage and computing) and other fields. use.

The data-driven future has arrived

"We are very optimistic about the technical and commercial development prospects of ReRAM memory from the aspects of density, energy efficiency ratio, cost, process and yield , so we make it our R&D focus!" said the relevant person in charge of Xinyuan Semiconductor.

Domestic memory is expected to "overtake in corners"

The core of the new type of memory is that in its development, it is necessary to add some special features to the traditional CMOS (abbreviation for complementary metal oxide semiconductor, a technology used to make large-scale integrated circuit chips or chips made with this technology) process. Materials or processes, the development of these special materials or processes needs to be verified by a lot of experiments and tests.

Traditional CMOS foundries may be limited by resources, and the iteration speed is slow, which affects the progress of process development. Although major domestic research institutes can speed up the iteration speed in the laboratory stage, there is no standard 12-inch mass production line. , the experimental results are often difficult to mass production.

Xinyuan's self-built 28/22nm ReRAM (resistive variable memory) 12-inch pilot production line solved the above problems. Drawing on the strengths of foundries and laboratories, it has fast iteration speed, flexible production lines, and independent and controllable intellectual property rights , making it possible to quickly realize ReRAM-related products.

Xinyuan Semiconductor technicians conduct equipment testing on the pilot line

"As the first 28/22nm ReRAM 12-inch pilot production line in mainland China , the smooth turn-on of our production line and the completion of product verification and mass production will greatly promote the development of China's new storage industry." The relevant person in charge of Xinyuan Semiconductor said, "In this field, the gap between domestic and foreign countries is currently small, and barriers have not yet been formed, which provides the possibility for China's memory industry to achieve "curve overtaking" ."