Not necessarily I guess. This is probably to test high-altitude engine performance on the ground instead of flying the aircraft test-bed in the future.So, this compressor will be part of an engine currently in development?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese Engine Development

- Thread starter jackbh

- Start date

So, this compressor will be part of an engine currently in development?

Pretty sure compressors like this one are meant to drive a constant airstream for wind tunnels. You need to simulate different flight conditions for ground based engine tests, which means your airstream isn’t static, and will have to change speeds based on the particular simulated speed you’re testing engine performance at.Not necessarily I guess. This is probably to test high-altitude engine performance on the ground instead of flying the aircraft test-bed in the future.

But the linked article did say that one of the application is for high altitude engine test.Pretty sure compressors like this one are meant to drive a constant airstream for wind tunnels. You need to simulate different flight conditions for ground based engine tests, which means your airstream isn’t static, and will have to change speeds based on the particular simulated speed you’re testing engine performance at.

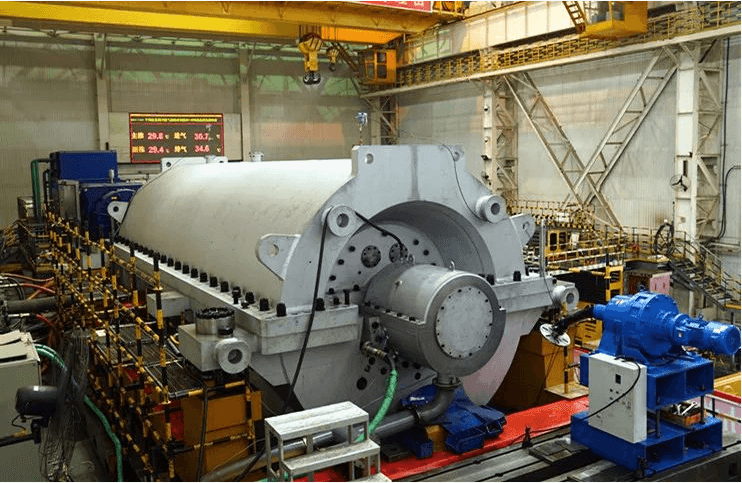

The super-large axial compressor unit AV140, innovatively developed by Shaanxi Blower (Group) Co., Ltd. has been successfully tested in the plant on September1st, each performance indexes of which has reached the international advanced level. The compressor unit, independently developed by Shaangu, is widely used in many industry processes such as high altitude aero-engine test station, super-large blast furnace, catalytic cracking, large air separation, pharmacy, nitric acid, sulphuric acid, long-distance gas transportation ,compression energy storage, etc.. The operation performance of the compressor has reached to the advance level in the world, with flowrate of 20,000 -25,000 m³/min and pressure ratio of 8-9. Its innovatively new high-efficiency blade profile and hollow shaft ensures the more stable and efficient operation of the overall unit.

I think the all the variable parameters can be simulated by controlling the test station, pressure, temperature and air speed.

Here is the Chinese version

Another application (2nd bold texts) related to aerospace and aircraft is "continues transonic wind tunnel" meaning air speed can be adjusted.AV140是目前全球最大的轴流压缩机,轮毂直径1.4米,该系列最大风量可以达到25000m³/min,采用陕鼓全新开发的高效叶型,压缩能力强,效率高、调节范围宽;采用空心转子,减轻了转子重量,提升了转子动力特性;独特的密封结构,为压缩机稳定运行保驾护航;合理的结构优化布局设计,压缩机稳定性好、噪音低,更加节能高效、绿色环保。此次试车成功的机组将应用于我国航空发动机高空试验台位的抽气系统领域。该机组同类型大型轴流压缩机机组可在我国航空航天连续式跨声速风洞试验、冶金特大型高炉、催化裂化、大型空分、制药、硝酸、硫磺制酸、远程气体输送、压缩储能等多领域进行应用。

Last edited:

High altitude engine testing for broader range of flight conditions requires wind tunnels that can simulate moving airstreams.But the linked article did say that one of the application is for high altitude engine test.

I think the all the variable parameters can be simulated by controlling the test station, pressure, temperature and air speed.

Here is the Chinese version

Another application (2nd bold texts) related to aerospace and aircraft is "continues transonic wind tunnel" meaning air speed can be adjusted.

Quickie

Colonel

But the linked article did say that one of the application is for high altitude engine test.

I think the all the variable parameters can be simulated by controlling the test station, pressure, temperature and air speed.

Here is the Chinese version

Another application (2nd bold texts) related to aerospace and aircraft is "continues transonic wind tunnel" meaning air speed can be adjusted.

It probably can be used to suck out the air from a low-pressure chamber to simulate the thin air in high altitudes. I suppose this is what was meant when the news report mentioned about "high altitude aero-engine test station".

by78

General

The has successfully completed testing. It will be used in the upcoming high-altitude engine test bench. It's capable of moving air at 20,000 to 25,000 cubic meters per minute and has a pressure ratio of 8 to 9, which is the highest in the world among industrial axial compressors. The unit has a total length of 11.5 meters, a width of 5.7 meters, and a height of 4.5 meters; the total weight is more than 400 tons. The core component of the hollow rotor is nearly 11 meters in length, weighs nearly 70 tons, and the inner diameter of the rotor is 1.4 meters.

So basically, China is going for something similar to . It will be a critical piece of infrastructure for developing future military as well as civilian engines, especially high-bypass turbofans. Quite a few of these large axial compressors will be installed at the facility, divided among the test cells. And just like the ASTF, I'm sure it will come with an onsite supercomputer as well. A milestone development for sure.

ASTF facility from the outside:

One of the large ASTF test cells, large enough for testing high-bypass turbofans:

Last edited:

I don't quite get what you are trying to say. Is there anything that can be tested for an engine in a low pressure chamber with static air stream? I mean if you can build a chamber big enough to house a full-size engine and maintain low pressure in it, that chamber is a wind tunnel, right. You just need to circulate the low pressure air in it from one side to the other while maintaining the low pressure.High altitude engine testing for broader range of flight conditions requires wind tunnels that can simulate moving airstreams.

Last edited:

yes, that is what it all about.It probably can be used to suck out the air from a low-pressure chamber to simulate the thin air in high altitudes. I suppose this is what was meant when the news report mentioned about "high altitude aero-engine test station".

@latenlazy, please ignore this, I in #5528 probably misunderstood your reply in #5527 as "this thing is not meant for high altitude test", probably a brain short-circuit in my head.I don't quite get what you are trying to say. Is there anything that can be tested for an engine in a low pressure chamber with static air stream? I mean if you can build a chamber big enough to house a full-size engine and maintain low pressure in it, that chamber is a wind tunnel, right. You just need to circulate the low pressure air in it from one side to the other while maintaining the low pressure.

Lol I was really confused with your reply but thanks for clarifying@latenlazy, please ignore this, I in #5528 probably misunderstood your reply in #5527 as "this thing is not meant for high altitude test", probably a brain short-circuit in my head.