Jura The idiot

General

I think we talk about these ships in this thread ...

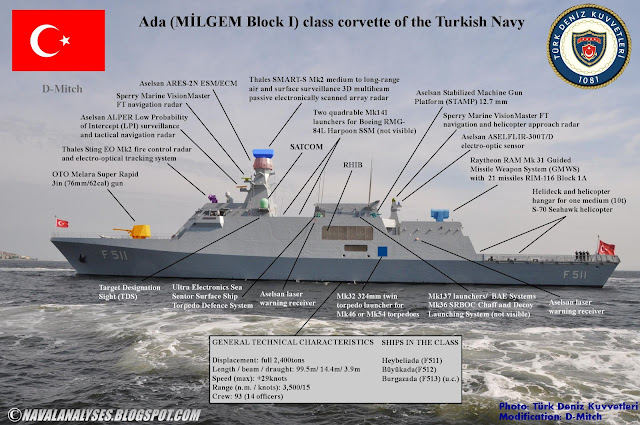

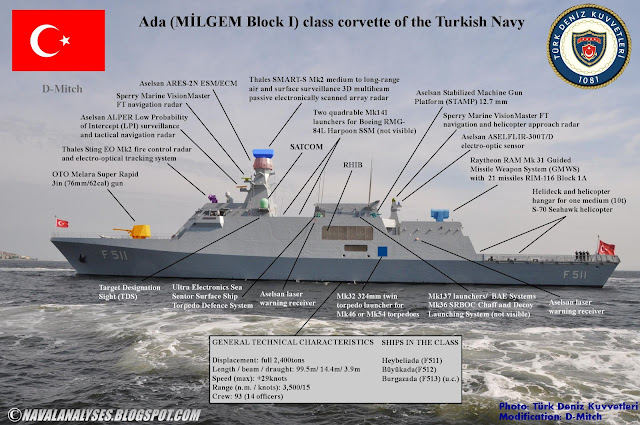

... and the article goes on with the description of the weaponry, protection, radars, etc.; source:The MILGEM project, from the Turkish words Milli Gemi (National Ship), is a Turkish national warship program with the aim to design and build locally a fleet of hi-tech stealth multipurpose corvettes and frigates that will replace older ships which are currently in service. Through this ambitious program, Turkey seeks to improve national military shipbuilding capacity and skills and ultimately to achieve independence from foreign weapon producers, designers and manufacturers. More than 50 local companies, including the largest Turkish defense firms such as Aselsan, Havelsan and RMK Marine, play a significant role in the MILGEM project, gaining invaluable experience in warship design and construction. The MILGEM Project Office of the Istanbul Naval Shipyard Command executes and coordinates the design, development and construction works of the MILGEM project since March 12, 2004. The programme initially included the construction of 12 ships in two batches (blocks, due to important differences among the batches). The first batch would have included eight (8) multipurpose corvettes the so-called MILGEM Block I (Ada; island in Turkish) class while the last four (4) would be of the TF-100 frigates equipped with vertical-launching system (VLS) for surface-to-air (SAM) missiles. This plan changed recently as the first batch will include only four corvettes of the Ada class, while all the rest ships will be designated as MILGEM Block II. In 2014, the head of naval projects for SSM, said that a request for proposals (RfP) for the Batch II (from ship 5) corvettes (also known as MILGEM -G) was expected to be issued by the end of the year. At the same time he said that work on the previously planned TF-100 project for a light frigate to replace some of Turkey's older MEKO 200 frigates had been stopped as "this role will now be covered by the Batch II MILGEM ". The new ships will have an increased length of about 10m and they will include in their equipment an Mk41 VLS for Evolved Sea Sparrow Missiles (ESSM), Phalanx CIWS instead of RAM (logically from the decommissioned Gabya-class frigates), two more quadruple SSM launchers, further combat system upgrades, new anti-torpedo system and diesel engines. The ships of the MILGEM Block I will replace gradually the six D'Estienne d'Orves-class/Burak class corvettes while the MILGEM Block II the non-modernized Gabya/O. H. Perry class frigates (4 in service) and the Yavuz (MEKO 200TN Track I) class frigates (4 in service). This year the designation name of the new Batch changed to I-class.

Till today (June, 2015) only two corvettes have been commissioned by the Turkish Navy and two more are in different phases of construction. The lead ship of the class, TCG Heybeliada (F-511) was launched at t the TNFC's Istanbul Naval Shipyard on September 27, 2008. The cost of the lead ship was around US$260 million. The ship entered in service on September 27, 2011. On the same day and at the same shipyard, the TCG Büyükada (F-512) was launched and exactly two years later, in 2013, she was commissioned into Turkish Navy. On the same day the keel for the third ship TCG Burgazada (F-513) was laid. However, the MILGEM programme encountered major setbacks in 2013 that cast doubt over the project's future. Under the original planning a nominated private Turkish shipyard was to work together with Istanbul Naval Shipyard on the third and fourth ships in Pendik in order to transfer the know-how required for the construction of subsequent ships in its own facility, and RMK Marine was selected in January 2013. However, contract negotiations were halted in mid-2013 when a complaint from SEDEF Shipyard sparked a probe. In August the prime minister's inspection office concluded that the tender for follow-on ships was not held in a competitive manner and should therefore be cancelled. The SSM's (Turkish Undersecretariat for Defence Industries) executive committee acknowledged the findings of the inspection office inquiry during a 26 September 2013 meeting and set out a revised procurement strategy in which it was decided that the fourth corvette would now also be built at Istanbul Naval Shipyard while a new tender was opened for the I-class ships. The experience and technological know-how gained with the MILGEM project will play an important role in determining the design characteristics and the development process of the anti-aircraft warfare TF-2000 class frigates.

The general characteristics of the class is a displacement of approximately 2,300tons at full load, length of 99.5m, beam of 14.4m, maximum speed of +29 knots and a range of 3,500n.m. with the cruising speed of 15 knots. The crew is only 93 people while there is accommodation for 106 passengers including flying crew and technicians (11 people). The propulsion is combined diesel and gas (CODAG) propulsion system, which consists of a gas-turbine and two diesel engines delivering a power of around 30,000kW. The ships carry one medium helicopter (S-70 Seahawk) which can be accommodated in a hangar. Additionally, each corvette carries two rigid-hulled inflatable boats (RHIB). The ships feature a steel hull and fragmentation resistant composite superstructure. Fore and aft masts and the funnel have been constructed with sea resistant aluminum alloys. The warships of the MILGEM project are designed to fully operate at sea state 5 and partially operate at sea state 6. Reduction and management of the ship signatures was taken as the major input during the whole design phase. Many classified precautions were taken in order to reduce hydrodynamic, acoustic, magnetic signature, Infrared Signature (IR), Radar Cross Section (RCS), and therefore, to achieve the specified level of stealth feature. Collective Protection Zones are designed to ensure the ships ability under NBC conditions. Locally designed degaussing system minimizes the magnetic signature for protection against the magnetic mines. The design focused on reduced Life Cycle Cost while the configuration is easily adaptable to technological improvements and changes due to operational requirements.

...