You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PLAN SCS Bases/Islands/Vessels (Not a Strategy Page)

- Thread starter lilzz

- Start date

Hendrik_2000

Lieutenant General

Yes...but even a year old it is impressive.

A magnificent reclamation job...when you consider the very small man made station that was there a few years ago, and what it is now.

Just incredible.

Yes it is ever wonder how they did it? Here is one monstrous machine that help building those artificial island

China’s domestically-developed dredger marvels the world

() 17:34, July 31, 2017

China’s development of heavy-duty machinery has earned so much pride for the country in recent years. The self-propelled cutter-suction dredger, Tianjing or Sky Whale, is one good example.

The vessel is the largest cutter-suction dredger in Asia. Financed by Tianjin Waterway Bureau Limited under China Communications Construction Company Ltd (CCCC), the dredger is co-designed by Shanghai Jiaotong University and German company, VOSTALMG. It was built by China Merchants Heavy Industry (Shenzhen) Company Ltd.

Surrounded by steel frames and crane arms, the vessel’s deck is more like a construction site. The only thing that distinguishes it from a real construction site is its clean environment. People on the vessel are required to put on safety helmets once they step out of the cabin.

China has a long history of dredging, though modern technology has since replaced human labor.

Tianjing has been hailed as a mighty tool for island-building because of its strong excavation and hydraulic reclamation ability. According to a crew member, Tianjing can excavate 4,500 cubic meters of mixture from the seabed each hour - the equivalence of a 0.5-meter-deep pit and a standard soccer field size.

The reamer of Tianjing

Cuts rocks as easy as mud!

The vessel’s reamer has endowed it with powerful ability. The reamer is normally inconspicuous in pictures, but people will be astonished when standing right in front of it. The diameter of small reamers is 2.8 meters, while that of larger ones could reach 3.15 meters, said Wang Ming’an, former Tianjing captain and vice general manager of the Overseas Business Division of the CCCC Tianjin Waterway Bureau Limited.

It was learned that the unit price of the cutter tooth on the reamer, which is used for excavation, is 1,500 RMB ($223). Driven by a 4,200-kilowatt variable-frequency motor, the cutter teeth could excavate moderately- and highly-weathered rocks with compression strength as high as 40 MPa.

“Concretes can be easily ground by the reamer,” said Wang, adding that rocks are as soft as mud for the machine.

Powerful self-propelling ability, automatic dredging control system

In addition, the dredger has two other “killer skills”: powerful self-propelling ability and advanced automatic dredging control system. The cockpit located on the top floor of the vessel is the “brain” that realizes the two functions.

Covering an area of about 40 or 50 square-meters, the cockpit offers a strong taste of high-tech style that can easily be associated with the flight deck of a spaceship in a sci-fi movie.

The automatic dredging control system lies in the cockpit, integrating all operations in a 2-square meter station. The remote control is operated just by clicking the mouse or pushing the buttons. Crew members can even take a cup of tea while excavating, a staff on the vessel explained.

Positioning and self-propelling systems are on the two sides of the dredging control station. The staff member said that cutter-suction dredgers are not new as they have been widely applied in engineering dredging projects.

However, most of them are not equipped with self-propelling systems. They depend on other ships to mobilize to different work points. As Asia’s first self-propelled cutter-suction dredger, Tianjing can sail to any part of the ocean.

The cockpit of Tianjing

Export limitations

On May 25, China’s Ministry of Commerce limited exports of large-scale engineering ships. Without government approval, exports of cutter-suction dredgers with reamer power equal to or larger than 500 kilowatts, excavation depth equal to or larger than 15 meters, and installed power equal to or larger than 2,000 kilowatts, are not allowed anymore.

Wang said all CCCC Tianjin Waterway Bureau Limited vessels are subjected to the export limitations. He added that their vessels could work in foreign countries, but purchases are not allowed.

According to Wang, when the dredger arrives at a construction site, a key pile with a diameter of 1.8 meters is then laid and a transverse axis arranged on both sides of the ship bow.

An axle beam weighing 1,100 tons reaches out to press the cutter in case the latter rebounds after touching hard sand and rocks under the sea, Wang explained. Tianjing’s mud conveyance distance is 6,000 meters.

Moves forward like walking in water

Tianjing looks like a walking person in water as its main and supporting piles submerge in turns.

Crew members do not feel bored as Tianjing is equipped with facilities such as dormitory, playroom, fitness room, laundry, medical room and canteen.

The average age of the crew is 28 years old. Usually, these young people have to work 3 consecutive months before they are allowed to have vacation.

How to keep the food and vegetables fresh is a challenge. Li Yuelai, Tianjing political commissioner and deputy Party secretary of the CCCC, said most vegetables were damaged by wind and storm after some time.

Tianjing has made China’s dredging industry comparable to the world’s leading companies, said a CCCC staff. Before 2005, Chinese dredging companies largely relied on imported equipment and the country’s dredger-building technology was undeveloped as a result of foreign blockade.

The able dredger has so far taken part in many hydraulic reclamation projects, Li said, emphasizing that Tianjing has attracted the attention of some foreign engineers.

Besides Tianjing, China has also developed a more advanced self-propelled cutter-suction dredger named Tiankun. It has a designed production capacity of 6,000 cubic meters per hour and cutter efficiency of 5,000 kilowatts, a CCCC staff said.

Capable of evacuating 35 meters in depth with maximum conveyance distance of 15,000 meters, Tiankun tops the world in terms of long-distance delivery capacity and other capabilities. The research and development of Tiankun has promoted the transformation of the country’s dredge-building technology from “Made in China” to “Created in China.”

Hendrik_2000

Lieutenant General

Now this is a surprise fast as speeding bullet From Japan time

I guess they need the power pack asap

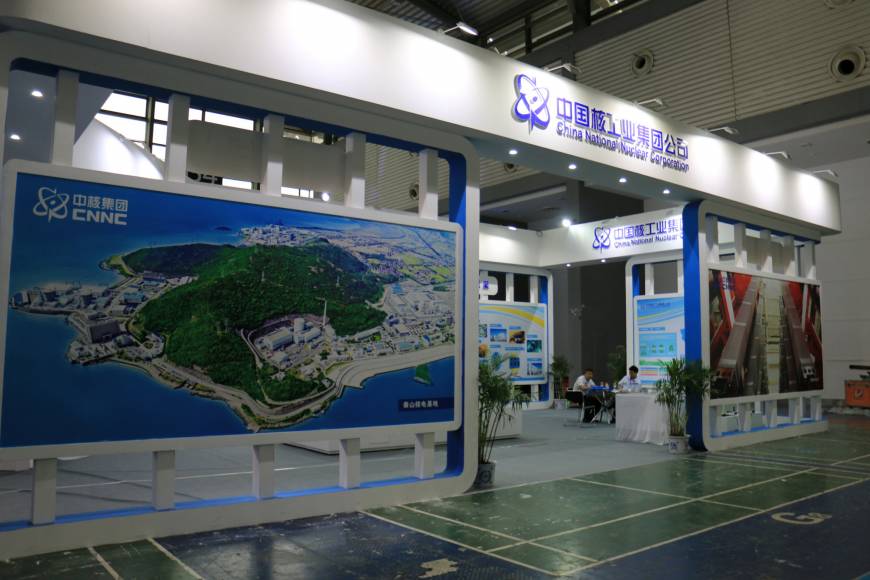

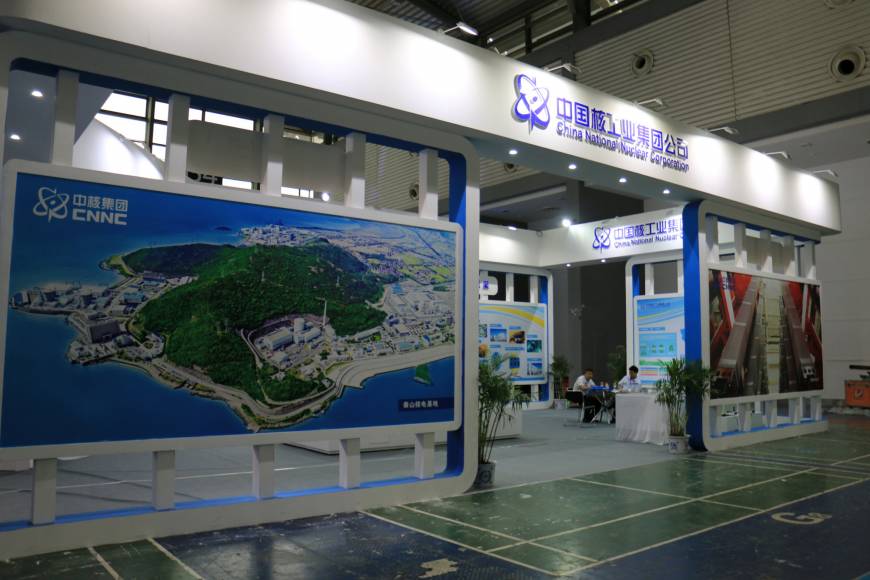

A booth of the China National Nuclear Corporation (CNNC) is pictured at an expo in Xian, China, in August. | REUTERS

/

China close to completing first offshore nuclear reactor

REUTERS

SHANGHAI – China’s first offshore nuclear reactor is set to be completed soon, engineers involved in the project said, bolstering Beijing’s maritime ambitions and stoking concerns about the potential use of atomic power in disputed island territories.

Beijing hopes offshore reactors will not only help win new markets, but also support state ambitions to become a “strong maritime power” by providing reliable electricity to oil and gas rigs as well as remote South China Sea islands.

Zhang Nailiang, engineer with the China Shipbuilding Industry Corporation (CSIC), said the technology was “mature” and the first demonstration project would be deployed soon at drilling platforms in northern China’s Bohai Sea.

“We are confident we should be able to get it finished very soon,” he told Reuters at an industry meeting this month. He declined to give an exact date, saying only that it would be ready well before 2020.

The demonstration project is being developed by a research team established by CSIC, China National Offshore Oil Corporation (CNOOC) and two reactor builders, China National Nuclear Corporation (CNNC) and China General Nuclear Power (CGN).

The direct use of military technology has aided progress, Zhang said, noting that other projects — including one launched by CNOOC and CGN last year — are still at the testing stage.

China has urged nuclear firms to develop technologies that will help boost domestic capacity and win projects abroad.

Zhang said floating reactors also served a wider political goal to strengthen China’s maritime presence, an aim reiterated by President Xi Jinping during his Communist Party Congress address this month.

“We in the nuclear and shipbuilding industries have a call of duty to construct a ‘strong maritime power,’ ” Zhang said in a speech.

China National Nuclear Power (CNNP), CNNC’s listed unit, launched a floating nuclear power subsidiary in August and also said the technology would help China become “a strong maritime power.”

Though CNNP did not mention the South China Sea, CGN and CNOOC’s rival project will be deployed in the region, which includes islands and reefs claimed by the Philippines, Brunei, Malaysia, Taiwan and Vietnam as well as China.

Experts warn offshore reactors could raise safety and security questions.

“The problem is the remoteness raises all kinds of questions about security, safety, economics and logistics,” said Mark Hibbs, senior fellow of the Nuclear Policy Program at the Carnegie Endowment for International Peace.

Offshore nuclear power could lead to the militarization of disputed waters, with China arguing “they have to beef up their presence” in order defend the reactors, Hibbs said.

“The big picture is that the Chinese see nuclear energy as a very strategic technology and as something that China will deploy to its strategic benefit,” he added.

I guess they need the power pack asap

A booth of the China National Nuclear Corporation (CNNC) is pictured at an expo in Xian, China, in August. | REUTERS

/

China close to completing first offshore nuclear reactor

REUTERS

SHANGHAI – China’s first offshore nuclear reactor is set to be completed soon, engineers involved in the project said, bolstering Beijing’s maritime ambitions and stoking concerns about the potential use of atomic power in disputed island territories.

Beijing hopes offshore reactors will not only help win new markets, but also support state ambitions to become a “strong maritime power” by providing reliable electricity to oil and gas rigs as well as remote South China Sea islands.

Zhang Nailiang, engineer with the China Shipbuilding Industry Corporation (CSIC), said the technology was “mature” and the first demonstration project would be deployed soon at drilling platforms in northern China’s Bohai Sea.

“We are confident we should be able to get it finished very soon,” he told Reuters at an industry meeting this month. He declined to give an exact date, saying only that it would be ready well before 2020.

The demonstration project is being developed by a research team established by CSIC, China National Offshore Oil Corporation (CNOOC) and two reactor builders, China National Nuclear Corporation (CNNC) and China General Nuclear Power (CGN).

The direct use of military technology has aided progress, Zhang said, noting that other projects — including one launched by CNOOC and CGN last year — are still at the testing stage.

China has urged nuclear firms to develop technologies that will help boost domestic capacity and win projects abroad.

Zhang said floating reactors also served a wider political goal to strengthen China’s maritime presence, an aim reiterated by President Xi Jinping during his Communist Party Congress address this month.

“We in the nuclear and shipbuilding industries have a call of duty to construct a ‘strong maritime power,’ ” Zhang said in a speech.

China National Nuclear Power (CNNP), CNNC’s listed unit, launched a floating nuclear power subsidiary in August and also said the technology would help China become “a strong maritime power.”

Though CNNP did not mention the South China Sea, CGN and CNOOC’s rival project will be deployed in the region, which includes islands and reefs claimed by the Philippines, Brunei, Malaysia, Taiwan and Vietnam as well as China.

Experts warn offshore reactors could raise safety and security questions.

“The problem is the remoteness raises all kinds of questions about security, safety, economics and logistics,” said Mark Hibbs, senior fellow of the Nuclear Policy Program at the Carnegie Endowment for International Peace.

Offshore nuclear power could lead to the militarization of disputed waters, with China arguing “they have to beef up their presence” in order defend the reactors, Hibbs said.

“The big picture is that the Chinese see nuclear energy as a very strategic technology and as something that China will deploy to its strategic benefit,” he added.

Hendrik_2000

Lieutenant General

So which reef are they going to build this time around Scarborough Shoal?. I already posted this news in the China shipbuilding thread

Daily Mail picked up this news

China's ISLAND-BUILDING machine: Beijing unveils giant vessel that can reclaim land with incredible speed and is set to be sent to South China Sea

today unveiled a powerful island-building machine to help reclaim more land in the disputed South China Sea.

The enormous ship, called Tiankun, can dredge 6,000 cubic meters (211,000 cubic feet) of mud every hour - roughly the size of 2.5 Olympic Swimming Pools.

It's more efficient than Tianjing, China's current flagship for construction on the South China Sea.

Tianjing reportedly built seven artificial islands within a year's time in the contested region that's also claimed by Philippines, Vietnam, , among other countries.

Scroll down for video

China's largest cutter-suction dredger Tiankun takes water on November 3, 2017 in Qidong

The enormous ship is expected to be used for building military bases on the South China Sea

China completes building of Asia's largest cutter suction dredge

Tiankun has been built so that Beijing could accelerate its 'military defence project' on the South China Sea, according to a report on .

China's state media reported that the self-propelled cutter-suction dredging ship was launched today at the port of Nantong, east China's Jiangsu Province.

It's said to be the most powerful dredging vessel China has ever built.

+11

Tiankun can smash underwater rocks as well as move sand, mud and water to construct islands

+11

It's 460 feet long and 91 feet wide and is the most powerful dredging vessel China has built

Read more:

Follow us: |

Measuring 140 meters (460 feet) long and 27.8 meters (91 feet) wide, Tiankun can smash underwater rocks as well as move sand, mud and water to construct man-made islands.

The ship can dig as deep as 35 metres (115 feet) into the sea. It can squirt liquid and debris to as far as 15 kilometres (9.3 miles) - the farthest for any dredging ships in the world, claimed People's Daily.

Tiankun is the sister vessel of Tianjing, which China has used to build military bases on a group of disputed islands known in China as Nansha Islands and in Philippines as Spratly Islands.

Chinese media claimed that Tianjing built in the South China Sea in 2015, and nearly within 18 months' time.

Tiankun is 1.3 times more efficient than Tianjing, meaning it could potentially build nine islands in one year.

It can dig deeper and move water, mud and sand farther than Tianjing. It's also said to have four different types of dredging cutters so it could break into different rock and mud.

The heavy-duty machinery is expected to enter service next June.

Read more:

Follow us: |

Daily Mail picked up this news

China's ISLAND-BUILDING machine: Beijing unveils giant vessel that can reclaim land with incredible speed and is set to be sent to South China Sea

- Powerful Tiankun could potentially build nine artificial islands in a year's time

- It's more efficient than Tianjing, China's current flagship on South China Sea

- The vessel was launched today and is expected to enter service next June

- Beijing is hoping to accelerate its 'military defence project' on disputed waters

today unveiled a powerful island-building machine to help reclaim more land in the disputed South China Sea.

The enormous ship, called Tiankun, can dredge 6,000 cubic meters (211,000 cubic feet) of mud every hour - roughly the size of 2.5 Olympic Swimming Pools.

It's more efficient than Tianjing, China's current flagship for construction on the South China Sea.

Tianjing reportedly built seven artificial islands within a year's time in the contested region that's also claimed by Philippines, Vietnam, , among other countries.

Scroll down for video

China's largest cutter-suction dredger Tiankun takes water on November 3, 2017 in Qidong

The enormous ship is expected to be used for building military bases on the South China Sea

China completes building of Asia's largest cutter suction dredge

Tiankun has been built so that Beijing could accelerate its 'military defence project' on the South China Sea, according to a report on .

China's state media reported that the self-propelled cutter-suction dredging ship was launched today at the port of Nantong, east China's Jiangsu Province.

It's said to be the most powerful dredging vessel China has ever built.

+11

Tiankun can smash underwater rocks as well as move sand, mud and water to construct islands

+11

It's 460 feet long and 91 feet wide and is the most powerful dredging vessel China has built

Read more:

Follow us: |

Measuring 140 meters (460 feet) long and 27.8 meters (91 feet) wide, Tiankun can smash underwater rocks as well as move sand, mud and water to construct man-made islands.

The ship can dig as deep as 35 metres (115 feet) into the sea. It can squirt liquid and debris to as far as 15 kilometres (9.3 miles) - the farthest for any dredging ships in the world, claimed People's Daily.

Tiankun is the sister vessel of Tianjing, which China has used to build military bases on a group of disputed islands known in China as Nansha Islands and in Philippines as Spratly Islands.

Chinese media claimed that Tianjing built in the South China Sea in 2015, and nearly within 18 months' time.

Tiankun is 1.3 times more efficient than Tianjing, meaning it could potentially build nine islands in one year.

It can dig deeper and move water, mud and sand farther than Tianjing. It's also said to have four different types of dredging cutters so it could break into different rock and mud.

The heavy-duty machinery is expected to enter service next June.

Read more:

Follow us: |

Jura The idiot

General

let's wait and seeSo which reef are they going to build this time around Scarborough Shoal?...

Photo taken on Nov. 3, 2017 shows the Chinese-made dredging vessel "Tian Kun Hao" at a shipyard of Shanghai Zhenhua Heavy Industry Co. Ltd. in Qidong, east China's Jiangsu Province. The vessel, the largest of its kind in Asia, started water testing in Jiangsu Friday. (Xinhua/Ding Ting)

Jura The idiot

General

now I read

Asia's largest dredging vessel begins water tests

Xinhua| 2017-11-03 18:02:04

Asia's largest dredging vessel begins water tests

Xinhua| 2017-11-03 18:02:04

A Chinese-made dredging vessel, the largest of its kind in Asia, started water testing in east China's Jiangsu Province Friday.

The 140-meter-long vessel, with the designed capacity to dredge 6,000 cubic meters per hour, can dig as deep as 35 meters under the sea floor.

The vessel named "Tian Kun Hao" was funded and designed by Tianjin Dredging Co. Ltd. associated with China Communication Construction Co. Ltd. (CCCC) and was built by Shanghai Zhenhua Heavy Industry Co. Ltd.

"The electronic vessel is able to dredge an area the size of a soccer field with a depth of one meter within one hour," said Wang Jian, deputy chief engineer of CCCC Tianjin Dredging.

He said on sea floor with rocks, the vessel's 6,600-kilowatt dredging equipment can mince hard rocks and pump the silt into the vessel, where it can be automatically blown out as far as 15,000 meters away.

The vessel is expected to be delivered in June next year.

Hendrik_2000

Lieutenant General

Look like this reactor will soon power the SCS sea island

At the moment it is undergoing final test before welded to the vessel. NO surprise Huludao is the naval shipyard that fabricate this vessel. Diesel power power gen set is not an option. It is just too expensive and does not have the capacity. Those Island need at least 40-60 MW because of the enormous power requirement for Desalination plant!

A model of the floating nuclear-power plant being developed by the China National Nuclear Corp. Photo: Xinhua

Floating nuke plants to power islands in South China Sea

These reactors can sail and also power drilling platforms in the ocean to expedite exploitation of oil, natural gas, as well as “combustible ice”

By ASIA TIMES STAFF NOVEMBER 3, 2017 4:18 PM

China’s first mobile nuclear reactor is undergoing final tests before being welded on a specially-designed vessel at a dock jointly operated by state-owned China National Nuclear Corp (CNNC) and China Shipbuilding Industry Corp in northeastern Liaoning province, recent reports by Chinese newspapers have said.

The same dock, in Huludao city near the Bohai Sea, was the birthplace of the People’s Liberation Army Navy’s first nuclear-powered submarine.

Analysts have associated these novel marine nuclear power stations to Beijing’s initiatives to militarise and “colonise” the South China Sea and turn its vast waters into a Chinese lake.

China built its first nuclear submarine in 1974, at the same dock where its first floating nuclear plant is being tested. Photo: Xinhua

China built its first nuclear submarine in 1974, at the same dock where its first floating nuclear plant is being tested. Photo: Xinhua

In August, CNNC spearheaded a 1-billion-yuan (US$151-million) scheme with four other corporate investors for a subsidiary specialised in oceanic nuclear-powered research and development.

Mobile nuclear reactors could power the many man-made islands being created in the South China Sea when transmitting electricity from the mainland would be expensive and conventional diesel generators can hardly quench the demand amid an expanding population of soldiers, constructors and residents.

The cost of diesel generation in the sea is 2 yuan per kilowatt hour, while the cost of nuclear generation could be as low as 0.9 yuan, China Business News quoted a China Atomic Energy Agency expert as saying.

Chinese vessels in waters around Mischief Reef in the disputed Spratly Islands in the South China Sea in this image taken by a P-8A Poseidon surveillance aircraft provided by the United States Navy on May 21, 2015. US Navy/via Reuters.

As many as 20 floating nuclear stations may be needed across the South China Sea for new chunks of land created on reefs and shoals, especially in the Paracel and Spratly archipelagos that are subject to conflicting territorial claims by China and Vietnam, the Philippines, Malaysia and Taiwan.

These reactors can also sail and power the many Chinese drilling platforms in the ocean to expedite exploitation of oil, natural gas, as well as “combustible ice” (a frozen mixture of water and concentrated natural gas found on the sea floor).

A CNNC official told Xinhua there is no technical issue standing in the way of these ocean-going reactors, but he remained tight-lipped about the specifications of these reactors.

Akademik Lomonosov, the Russian floating nuclear-power station that is nearing commercialisation, has two KLT-40 naval propulsion reactors providing 70MW of electricity or 300MW of heat, enough for a city with a population of 200,000. It could also be modified as a desalination plant producing 240,000 cubic meters of fresh water per day. China’s mobile reactors may be of a similar configuration.

Analysts believe that given China has built miniaturised reactors to propel its submarines since the 1970s, and with development of the nation’s first nuclear-powered aircraft carriers being revved up, tapping the same technology and talent pool to build sea-going nuclear-power plants is a natural move that should not surprise anyone.

At the moment it is undergoing final test before welded to the vessel. NO surprise Huludao is the naval shipyard that fabricate this vessel. Diesel power power gen set is not an option. It is just too expensive and does not have the capacity. Those Island need at least 40-60 MW because of the enormous power requirement for Desalination plant!

A model of the floating nuclear-power plant being developed by the China National Nuclear Corp. Photo: Xinhua

Floating nuke plants to power islands in South China Sea

These reactors can sail and also power drilling platforms in the ocean to expedite exploitation of oil, natural gas, as well as “combustible ice”

By ASIA TIMES STAFF NOVEMBER 3, 2017 4:18 PM

China’s first mobile nuclear reactor is undergoing final tests before being welded on a specially-designed vessel at a dock jointly operated by state-owned China National Nuclear Corp (CNNC) and China Shipbuilding Industry Corp in northeastern Liaoning province, recent reports by Chinese newspapers have said.

The same dock, in Huludao city near the Bohai Sea, was the birthplace of the People’s Liberation Army Navy’s first nuclear-powered submarine.

Analysts have associated these novel marine nuclear power stations to Beijing’s initiatives to militarise and “colonise” the South China Sea and turn its vast waters into a Chinese lake.

In August, CNNC spearheaded a 1-billion-yuan (US$151-million) scheme with four other corporate investors for a subsidiary specialised in oceanic nuclear-powered research and development.

Mobile nuclear reactors could power the many man-made islands being created in the South China Sea when transmitting electricity from the mainland would be expensive and conventional diesel generators can hardly quench the demand amid an expanding population of soldiers, constructors and residents.

The cost of diesel generation in the sea is 2 yuan per kilowatt hour, while the cost of nuclear generation could be as low as 0.9 yuan, China Business News quoted a China Atomic Energy Agency expert as saying.

Chinese vessels in waters around Mischief Reef in the disputed Spratly Islands in the South China Sea in this image taken by a P-8A Poseidon surveillance aircraft provided by the United States Navy on May 21, 2015. US Navy/via Reuters.

As many as 20 floating nuclear stations may be needed across the South China Sea for new chunks of land created on reefs and shoals, especially in the Paracel and Spratly archipelagos that are subject to conflicting territorial claims by China and Vietnam, the Philippines, Malaysia and Taiwan.

These reactors can also sail and power the many Chinese drilling platforms in the ocean to expedite exploitation of oil, natural gas, as well as “combustible ice” (a frozen mixture of water and concentrated natural gas found on the sea floor).

A CNNC official told Xinhua there is no technical issue standing in the way of these ocean-going reactors, but he remained tight-lipped about the specifications of these reactors.

Akademik Lomonosov, the Russian floating nuclear-power station that is nearing commercialisation, has two KLT-40 naval propulsion reactors providing 70MW of electricity or 300MW of heat, enough for a city with a population of 200,000. It could also be modified as a desalination plant producing 240,000 cubic meters of fresh water per day. China’s mobile reactors may be of a similar configuration.

Analysts believe that given China has built miniaturised reactors to propel its submarines since the 1970s, and with development of the nation’s first nuclear-powered aircraft carriers being revved up, tapping the same technology and talent pool to build sea-going nuclear-power plants is a natural move that should not surprise anyone.

Last edited:

It can squirt liquid and debris to as far as 15 kilometres (9.3 miles) - the farthest for any dredging ships in the world, claimed People's Daily.

I am going to need to see that

None. Unless CPC orders them to.So which reef are they going to build this time around Scarborough Shoal?

Hendrik_2000

Lieutenant General

Mass production of fuel rods for Chinese nuclear plants at sea has begun.