Tsinghua News Network, January 18. According to the China Manned Space Engineering Office, at 22:27 on January 17, 2024, Beijing time, the Long March 7 Yao-8 carrier rocket carrying the Tianzhou-7 cargo spacecraft was launched from Wenchang Aerospace in China. After the launch, the Tianzhou-7 cargo spacecraft successfully separated from the rocket and entered the predetermined orbit about 10 minutes later. Afterwards, the spacecraft's solar panels were deployed smoothly, making the launch a complete success. The Tianzhou-7 cargo spacecraft successfully completed the status setting after entering orbit, and successfully docked at the rearward port of the Tianhe core module of the space station at 1:46 on January 18, 2024, Beijing time.

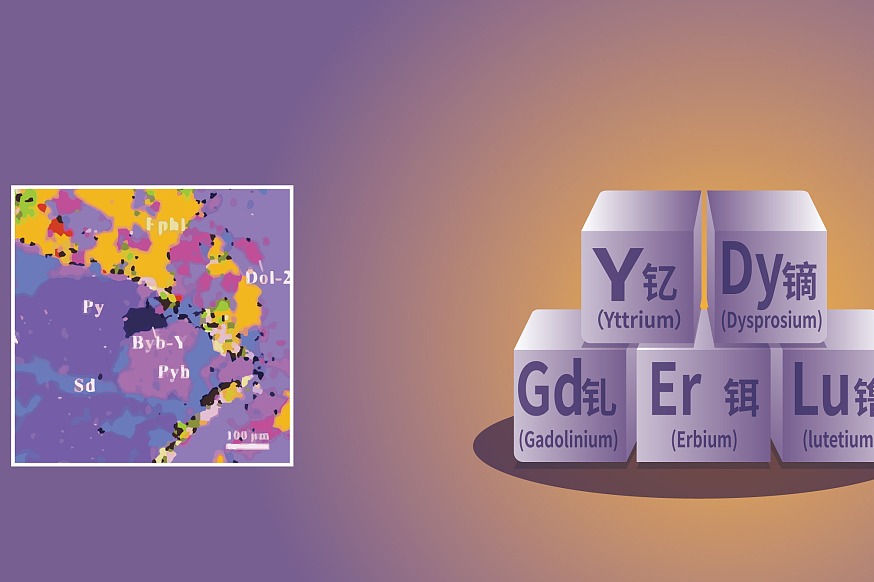

The length of the Tianzhou-7 cargo spacecraft cabin exceeds 6m and the maximum diameter exceeds 3m. Its efficient and high-quality processing is a worldwide problem. To solve this problem, Professor Liu Xinjun's team from the Department of Mechanical Engineering of Tsinghua University sought inspiration from the working methods of living organisms in nature, and were inspired by the common phenomena of "mobile positioning and local refinement of work" such as long-necked weevils building cocoons, woodpeckers pecking wood, and craftsmen carving works. Inspired by this, he took the lead in proposing a life-like behavior bionic operation mode of "large-scale positioning + local five-axis fine carving", which can realize in-situ processing in which the workpiece remains stationary and the processing equipment moves. Furthermore, applying the principle of parallel mechanism, a five-degree-of-freedom parallel mechanism with both lightweight, high-efficiency and high-precision performance was invented. Then, using functions similar to those of the human hand, this parallel mechanism that can achieve five-axis motion was used as a manipulator to innovate. A mobile hybrid processing robot (shown in Figure 1) was designed and developed. It consists of an AGV that can move in a wide range, a high-rigidity two-degree-of-freedom mechanical arm with a parallel structure, and a five-degree-of-freedom parallel mechanism module. constitute.

When a certain local feature of a component needs to be processed, the AGV first moves to a to-be-determined position under the guidance of iGPS, then the fulcrum and auxiliary mechanism support the AGV chassis to fix it, and then swings the robotic arm to a certain position and locks the drive motor. In this way, the AGV and the robotic arm can form a high-stiffness rigid body. After the AGV and the manipulator are ready, the parallel motion manipulator at the end determines the relative position of the tool and the feature to be processed under visual/tactile perception, and then the local feature can be processed. The maximum local error is within a diameter of 300mm. It can be controlled within 0.04mm, and the global processing accuracy can reach 0.1mm within a 6m scale. Because the end of this mobile robot is a manipulator that can perform precise operations, and it can complete processing tasks like a craftsman, this mobile hybrid processing robot is also called a "machine craftsman."

The invention and development of this "machine craftsman" has solved the problem of efficient and high-quality in-situ manufacturing of the Tianzhou-7 cargo spacecraft cabin and sections (Figure 2). What is different from assisting the manufacturing of Tianzhou-6 is that this time The robot has made new progress in high-precision positioning. It adopts a measurement method that integrates vision and contact probes to increase the positioning accuracy from 0.04mm to 0.02mm. It also improves the independent controllability of in-situ manufacturing technology for aerospace products. This is a big step forward and can also be applied to shield tunneling, gas turbines, aviation and other fields.

Relevant work is supported by the National Natural Science Foundation of China's "Research on Basic Theory and Key Technologies of Integrated Robots" major research program, the National Intelligent Robot Key Research and Development Program, and the Beijing Science and Technology Plan's Intelligent Manufacturing Technology Innovation and Cultivation Special Project.