You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

News on China's scientific and technological development.

- Thread starter Quickie

- Start date

According to the website of the State Asset Management and Supervision Commission, Zhejiang China Telecom and Huaneng (Zhejiang) Energy Development Co., Ltd. recently opened China's 5G virtual power plant. The first real-time planning 5G virtual power plant project. It is known that the project uses 5G layer cutting technology to separate the control data of the virtual power plant from the public network, realize distributed power supply and safely control the load.

broadsword

Brigadier

Chinese team develops world’s first ceramic material that can bend like metal

Flexible silicon nitride ceramics could boost performance of aerospace and automobile engines, according to paper

The technology could also be used to make better artificial joints and wind turbine components, scientist says

Zhang Tong in Beijing

Chinese scientists have developed the world’s first ceramic material that can bend like metal, a technology that could boost the performance of engines and lead to better artificial joints.

Plasticity and strength were previously considered opposing qualities of ceramics – improvement in one typically meant a decline in the other. But the new material, which has the hardness of ceramic and the flexibility of metal, is the first example of scientists improving both at the same time, according to materials scientist Chen Kexin, who led the research.

“This ceramic can bring technological revolutions to many industries,” said Chen, a professor with the department of engineering and material sciences at the National Natural Science Foundation of China.

Chen and colleagues at Tsinghua University published their findings in the peer-reviewed journal Science on October 27. The discovery “could lead to materials that are lighter and stronger than even the best metal alloys of today”, Erkka Frankberg of Tampere University in Finland wrote in a perspective article published in the same issue of Science.

“There has been research on plasticity of ceramics around the world since I started my career 30 years ago. It can be said that today we have finally achieved a breakthrough on that topic,” Chen said.

The researchers used silicon nitride to make nanopillars containing two types of crystal structures. When subjected to external force, one type of crystal structure can transform into the other, allowing the material to bend then resume its original shape.

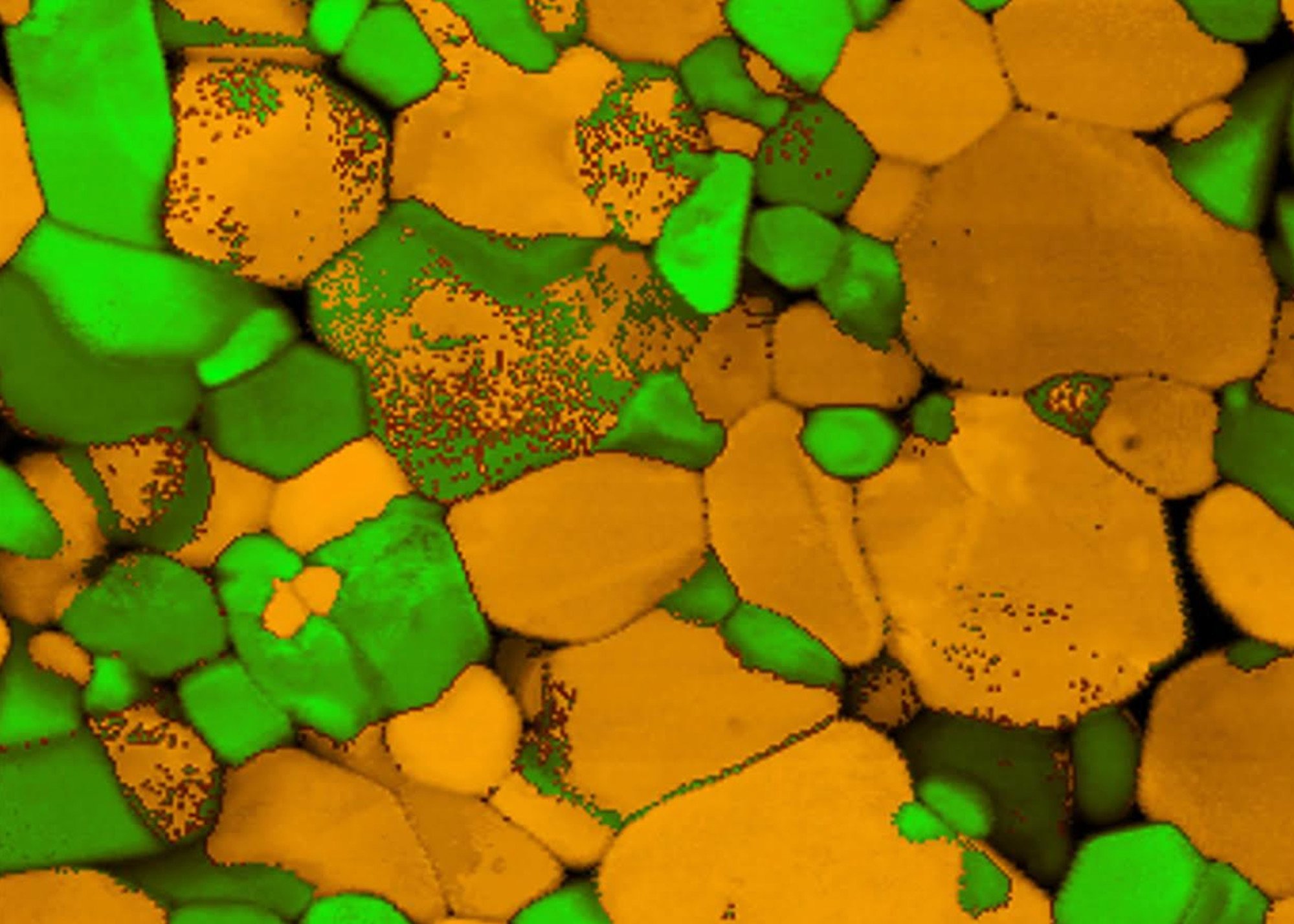

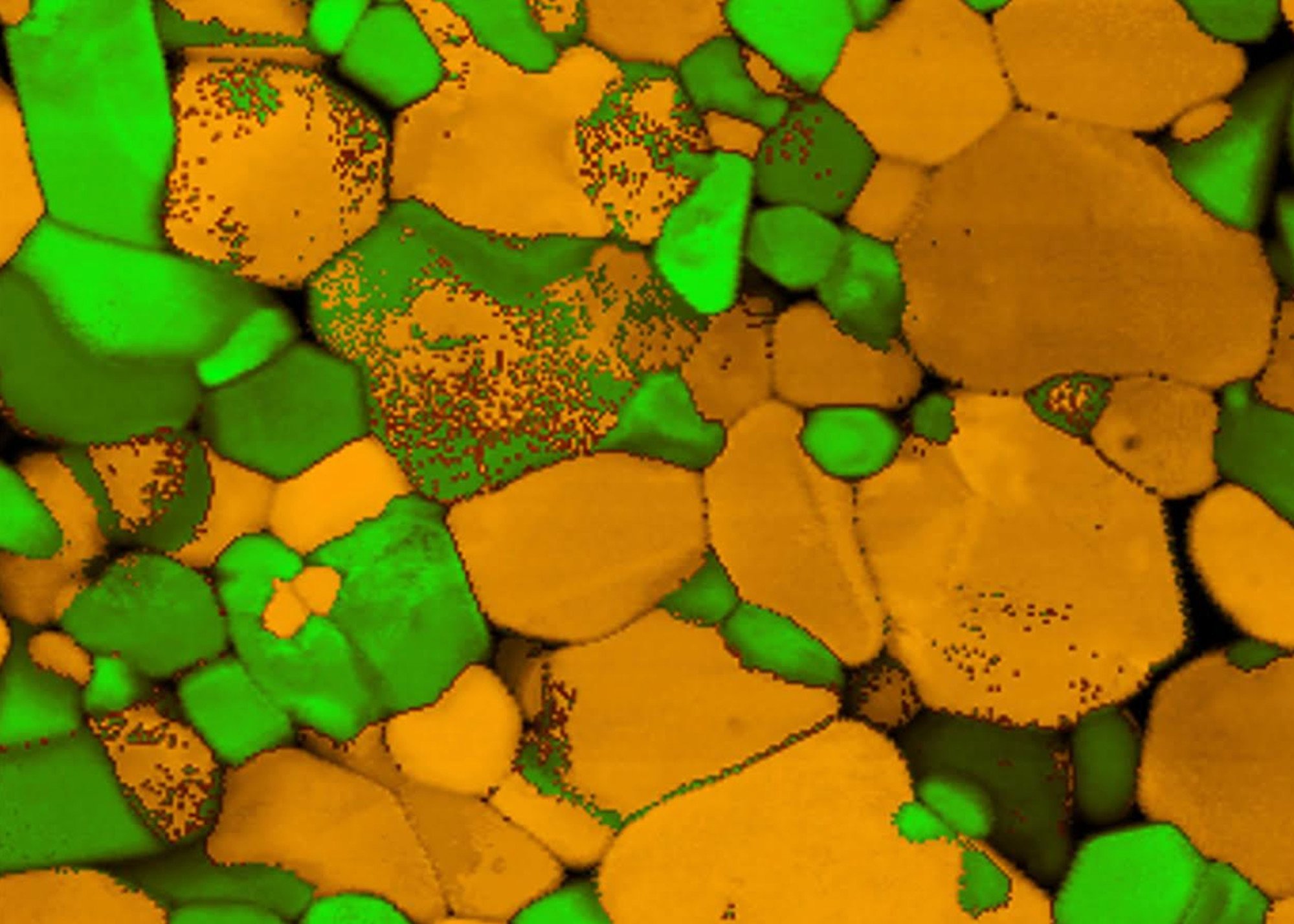

The researchers used silicon nitride to make nanopillars containing two types of crystal structures, shown here in green and orange. Photo: Chen Kexin

The material could be especially useful for building aerospace engines. Ceramic materials are strong and light and can tolerate high temperatures. Flexible ceramic engines could operate at much higher temperatures than traditional alloy engines and with much better fuel efficiency.

A ceramic engine would be much lighter than an alloy engine, allowing it to accelerate much more quickly. Reducing the engine weight relieves stress on other components.

The material could also be used in automobile engines. Because ceramic materials have higher heat resistance than alloys, a ceramic engine could have a smaller coolant tank. The higher combustion temperatures of a ceramic engine could result in better thrust and fewer pollutants.

Silicon nitride ceramics are lightweight, biocompatible and antibacterial, making them a potential alternative for use in joint replacements. Most artificial joints are made of metal and need to be replaced every 10 years, which is expensive and painful for patients.

“Artificial joints made with ceramics can last a lifetime after implantation,” Chen said.

He said the material could also be used to make bearings used in wind turbines – a key component that connects the generator to the fan blades. Each bearing must withstand several tonnes of pressure during operation, and its durability determines the service life of the entire system.

“Our flexible silicon nitride ceramics could be used to manufacture bearings with a longer lifetime, thereby reducing the average cost of wind power,” Chen said.

“It is possible to produce this flexible ceramic material on a large scale based on our experiments. There is an obvious price advantage in the field of high-end equipment.”

For example, producing the single-crystal turbine blades used in jet engines requires expensive rare earth materials, while the most expensive silicon nitride sells for about US$200 per kilogram, he said.

“We will keep improving this ceramic material on the basis of our current work. Once you open a door, there is a broad world behind,” Chen said.

Flexible silicon nitride ceramics could boost performance of aerospace and automobile engines, according to paper

The technology could also be used to make better artificial joints and wind turbine components, scientist says

Zhang Tong in Beijing

Chinese scientists have developed the world’s first ceramic material that can bend like metal, a technology that could boost the performance of engines and lead to better artificial joints.

Plasticity and strength were previously considered opposing qualities of ceramics – improvement in one typically meant a decline in the other. But the new material, which has the hardness of ceramic and the flexibility of metal, is the first example of scientists improving both at the same time, according to materials scientist Chen Kexin, who led the research.

“This ceramic can bring technological revolutions to many industries,” said Chen, a professor with the department of engineering and material sciences at the National Natural Science Foundation of China.

Chen and colleagues at Tsinghua University published their findings in the peer-reviewed journal Science on October 27. The discovery “could lead to materials that are lighter and stronger than even the best metal alloys of today”, Erkka Frankberg of Tampere University in Finland wrote in a perspective article published in the same issue of Science.

“There has been research on plasticity of ceramics around the world since I started my career 30 years ago. It can be said that today we have finally achieved a breakthrough on that topic,” Chen said.

The researchers used silicon nitride to make nanopillars containing two types of crystal structures. When subjected to external force, one type of crystal structure can transform into the other, allowing the material to bend then resume its original shape.

The researchers used silicon nitride to make nanopillars containing two types of crystal structures, shown here in green and orange. Photo: Chen Kexin

The material could be especially useful for building aerospace engines. Ceramic materials are strong and light and can tolerate high temperatures. Flexible ceramic engines could operate at much higher temperatures than traditional alloy engines and with much better fuel efficiency.

A ceramic engine would be much lighter than an alloy engine, allowing it to accelerate much more quickly. Reducing the engine weight relieves stress on other components.

The material could also be used in automobile engines. Because ceramic materials have higher heat resistance than alloys, a ceramic engine could have a smaller coolant tank. The higher combustion temperatures of a ceramic engine could result in better thrust and fewer pollutants.

Silicon nitride ceramics are lightweight, biocompatible and antibacterial, making them a potential alternative for use in joint replacements. Most artificial joints are made of metal and need to be replaced every 10 years, which is expensive and painful for patients.

“Artificial joints made with ceramics can last a lifetime after implantation,” Chen said.

He said the material could also be used to make bearings used in wind turbines – a key component that connects the generator to the fan blades. Each bearing must withstand several tonnes of pressure during operation, and its durability determines the service life of the entire system.

“Our flexible silicon nitride ceramics could be used to manufacture bearings with a longer lifetime, thereby reducing the average cost of wind power,” Chen said.

“It is possible to produce this flexible ceramic material on a large scale based on our experiments. There is an obvious price advantage in the field of high-end equipment.”

For example, producing the single-crystal turbine blades used in jet engines requires expensive rare earth materials, while the most expensive silicon nitride sells for about US$200 per kilogram, he said.

“We will keep improving this ceramic material on the basis of our current work. Once you open a door, there is a broad world behind,” Chen said.

supercat

Colonel

A robot for harvesting tomatoes:

China's innovation is nothing short of explosive nowadays:

China's innovation is nothing short of explosive nowadays:

Chinese scientists solved a major problem in alumina industry. They developed new technologies to make use of low grade bauxite, in particular those with high concentration of carbon and sulphur.

据了解,该技术可将这些原来难以利用的高硫高碳铝土矿变成高品质有效资源,为我国高硫铝土矿的高效高质利用和氧化铝工业的健康可持续发展提供了可靠的技术支撑,经济和社会效益显著,整体技术达到国际领先水平。

西安科研团队攻克氧化铝工业难题

记者从西安建筑科技大学粉体工程研究所获悉:该校陈延信教授科研团队经过研究探索,攻克氧化铝工业难题,在低品质铝土矿焙烧提质理论与技术上取得重大突破并实现工业化应用。技术成果在相关项目应用一年即新增产值22.78亿元,使长期沉寂的“呆矿”成为“金矿”。据了解,该技术可将这些原来难以利用的高硫高碳铝土矿变成高品质有效资源,为我国高硫铝土矿的高效高质利用和氧化铝工业的健康可持续发展提供了可靠的技术支撑,经济和社会效益显著,整体技术达到国际领先水平。

World-leading 3D printing tech widely used on China’s newly developed warplane

By Published: Nov 26, 2022 03:08 PM

A Chinese FC-31 stealth fighter has its test flight ahead of the 10th China International Aviation and Aerospace Exhibition in Zhuhai, South China's Guangdong Province, Nov 10, 2014. Photo: Xinhua

China's aviation industry has started applying world-leading 3D printing technologies on new-generation warplanes, with 3D printed parts widely used on a newly developed aircraft that made its maiden flight not long ago, said a leading developer.

3D printed parts enjoy advantages including high structural strength, light weight, long service life, low cost and fast manufacturing, experts said on Saturday.

"We are applying 3D printing technologies on aircraft on a large scale at an engineering level, and we are in a world-leading position," Doctor Li Xiaodan, a member of the Luo Yang Youth Commando at Shenyang Aircraft Company's craft research institute, told China Central Television (CCTV) on Saturday.

With the growing demands of new-type warplane development in terms of weight reduction, lifespan extension, cost control and rapid response, previous production approaches reached a ceiling by 2013, and the Luo Yang Youth Commando was established to promote a breakthrough, CCTV reported.

The team is named after Luo Yang, head of production of China's J-15 carrier-based fighter jet who died of a heart attack brought on by overworking 10 years ago on November 25, 2012, after observing the country's first-ever aircraft carrier landing tests that featured the jet.

The Luo Yang Youth Commando made innovations with no reference and completely mastered the 3D printing technologies, also known as additive manufacturing, and it has been using the latest 3D printing equipment to produce components used by China's new-generation warplanes, CCTV reported.

"3D printed parts were widely used on a newly developed aircraft that has made its maiden flight not long ago," CCTV quoted Li as saying.

Compared with conventional manufacturing methods, which need to use rivets or welding to connect parts together, 3D printing builds an integrated part, which enjoys a higher structural strength, which also leads to a longer service life, Song Zhongping, a Chinese military expert and TV commentator, told the Global Times on Saturday.

It also enables manufacturers to use no extra materials, which makes the part lighter, Song said. Another advantage is that 3D printing is fast, and parts can be quickly manufactured, which makes logistics support simpler and less costly, he said.

The Shenyang Aircraft Company, a subsidiary of the state-owned Aviation Industry Corporation of China, is known as the cradle of Chinese fighters, having built main combat warplanes of the Chinese People's Liberation Army (PLA) from the country's first generation J-5 fighter jet to the modern J-15 carrier-based fighter jet and the J-16 multirole fighter jet.

It also developed China's second stealth fighter jet, the FC-31, which is available for export, and is also expected to be further developed into China's next generation carrier-based fighter jet, according to analysts.

3D printing technologies have now been implemented in major aircraft manufacturing factories of the Chinese aviation industry, making China a country to use such technologies on a large scale, the CCTV report said.

This means aircraft manufactured not only by Shenyang Aircraft Company, but also by other Chinese aircraft makers are using 3D printing technologies, observers said.

supercat

Colonel

50 MW gas turbine:

So Zambia will have a 5G network before the U.S. and many European countries.

So Zambia will have a 5G network before the U.S. and many European countries.

Huawei-supported 5G network launched in Zambia

Technology Group grabbed the top share in both large panels for TVs and small and medium panels for phones and tablets, in liquid crystal displays sector. BOE was also picked by Apple as a supplier of OLED displays for iPhones..

by 2025, BOE will be the largest supplier of OLED panel in the world.

View attachment 102523View attachment 102524View attachment 102525View attachment 102526

Is BOE getting bigger than even LG in oled panels? What type of panels are Hisense and TCL using?