Since the SEMI Thread is under lock I like to share with you my mentor @Oldschool post .

Filling the blank of domestic etching process application, NAURA assists Shanghai ICRD 14nm SADP independent process research and development

2019-12-05 14:55Official Account of Semiconductor Investment Alliance

focus on

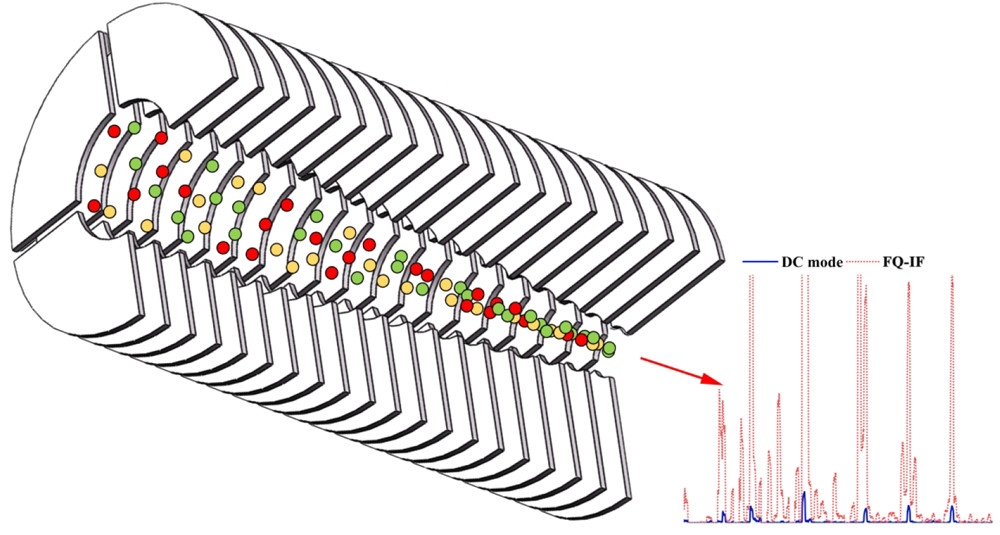

On November 21, Shanghai Integrated Circuit Research and Development Center Co., Ltd. (ICRD) and NAURA jointly announced that ICRD completed the 14nm fin using domestic equipment such as NMC612D Inductively Coupled Plasma (ICP) etcher. The independent development of the related process of self-aligned double pattern (14nm FinFET SADP) of the transistor, all process indicators have reached the mass production requirements, and significant progress has been made in the 14nm core process technology of integrated circuits.

ICRD uses domestic integrated circuit equipment for core process research and development. North Huachuang NMC 612D ICP etching machine is used as the core etching process equipment. Its process performance will directly affect the process performance and yield of fin transistor devices. With its excellent etching The technical advantages of morphology control, uniformity control, lower etching damage, and higher etching selectivity ratio, etc., NMC612D ICP etching machine of NAURA has made a significant contribution to the successful development of related processes, and has contributed to the successful development of 5nm The independent development of SAQP technology has laid a solid foundation.

The successful application of NMC612D inductively coupled plasma etcher in ICRD's 14nm FinFET SADP process development is a major milestone achieved by the strategic cooperation between ICRD and NAURA, which fills the 14nm process of domestic high-end integrated circuit equipment in the field of advanced integrated circuit technology. The blank of FinFET SADP etching process application proves that the performance of the domestic machine has reached the advanced level in the industry. (Proofreading/Pictures)

baijiahao.baidu.com

baijiahao.baidu.com

Filling the blank of domestic etching process application, NAURA assists Shanghai ICRD 14nm SADP independent process research and development

2019-12-05 14:55Official Account of Semiconductor Investment Alliance

focus on

On November 21, Shanghai Integrated Circuit Research and Development Center Co., Ltd. (ICRD) and NAURA jointly announced that ICRD completed the 14nm fin using domestic equipment such as NMC612D Inductively Coupled Plasma (ICP) etcher. The independent development of the related process of self-aligned double pattern (14nm FinFET SADP) of the transistor, all process indicators have reached the mass production requirements, and significant progress has been made in the 14nm core process technology of integrated circuits.

ICRD uses domestic integrated circuit equipment for core process research and development. North Huachuang NMC 612D ICP etching machine is used as the core etching process equipment. Its process performance will directly affect the process performance and yield of fin transistor devices. With its excellent etching The technical advantages of morphology control, uniformity control, lower etching damage, and higher etching selectivity ratio, etc., NMC612D ICP etching machine of NAURA has made a significant contribution to the successful development of related processes, and has contributed to the successful development of 5nm The independent development of SAQP technology has laid a solid foundation.

The successful application of NMC612D inductively coupled plasma etcher in ICRD's 14nm FinFET SADP process development is a major milestone achieved by the strategic cooperation between ICRD and NAURA, which fills the 14nm process of domestic high-end integrated circuit equipment in the field of advanced integrated circuit technology. The blank of FinFET SADP etching process application proves that the performance of the domestic machine has reached the advanced level in the industry. (Proofreading/Pictures)

Last edited: