The University of Science and Technology of China has made important progress in the development of biomimetic nanocomposite membranes for aerospace protection

Polyimide films are an excellent material for "protective clothing" for aerospace equipment because of their excellent mechanical properties, excellent thermal stability and outstanding chemical resistance. However, like other hydrocarbon polymers, polyimide materials are highly susceptible to attack by atomic oxygen in the space environment, resulting in a dramatic degradation of their physical and mechanical properties. There is no good solution for this problem. In addition, extreme environments such as cosmic ray radiation and space debris impact also put their stability to a severe test.

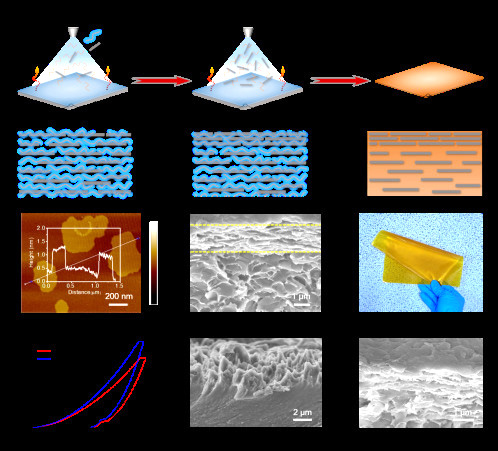

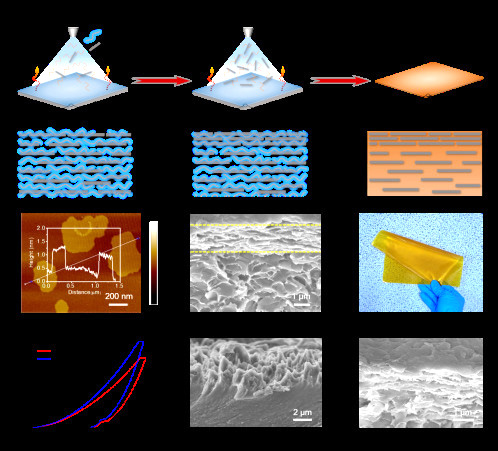

Recently, academician Yu Shuhong's team at the Chinese University of Science and Technology has developed a new polyimide - nano-mica composite film material for space protection applications, which adopts a unique bionic design to significantly improve its mechanical properties and tolerance to extreme environments in space. Inspired by the "brick-mud" layer structure of natural mother-of-pearl, the researchers have cleverly designed and constructed a polyimide-mica nanocomposite film with a double-layer pearl-like layer structure, so that the top layer is distributed with denser mica nanosheets, and with the advantages of the intrinsic properties of mica and the most constructed unit, the mechanical properties of the material are effectively improved while the top layer is more resistant to atoms. At the same time, the resistance of the top layer to atomic oxygen, ultraviolet radiation and space debris has also been significantly improved.

The researchers used mica nanosheets with excellent mechanical properties and UV shielding function, which can be prepared in macro quantities, as the building blocks and co-assembled with polyimide precursors to obtain polyimide-mica nanocomposite films, using the superior intrinsic properties of mica to compensate for the deficiencies of polyimide. In this study, the researchers constructed a polyimide-mica nanocomposite film with a double-layer pearl-like layer structure by changing the composition ratio and using a combination of spraying and thermal curing method, which resulted in a denser mica nanosheet in the top layer. This design strategy not only achieves effective improvement of the mechanical properties of the material, but also provides higher resistance to atomic oxygen, UV radiation and space debris on its upper surface.

It was shown that the tensile strength, Young's modulus and surface hardness of this new bionanocomposite film were 125 MPa, 2.2 GPa and 0.37 GPa, respectively, which were 45%, 100% and 68% higher than those of pure polyimide film. Due to the unique bilayer mother-of-pearl-like structure and the inherent performance advantages of mica nanosheets, the resulting bilayer polyimide-mica composite films exhibit superior atomic oxygen tolerance, which is significantly better than pure polyimide films, polyimide-mica composite films with single-layer mother-of-pearl-like structure and previously reported polyimide based composites. In addition, its UV aging resistance (313 nm) and high temperature stability (380 °C) are also significantly improved compared to pure PI films.

This polyimide-mica nanocomposite film with a bilayer mother-of-pearl-like structure is expected to replace the existing polyimide-based composite film materials as an effective new outer protective material for spacecraft and thus for use in low orbit environments. The unique design strategy of the bilayer mother-of-pearl-like structure proposed in this study also provides new ideas for the design and construction of other high-performance nanocomposites.

Polyimide films are an excellent material for "protective clothing" for aerospace equipment because of their excellent mechanical properties, excellent thermal stability and outstanding chemical resistance. However, like other hydrocarbon polymers, polyimide materials are highly susceptible to attack by atomic oxygen in the space environment, resulting in a dramatic degradation of their physical and mechanical properties. There is no good solution for this problem. In addition, extreme environments such as cosmic ray radiation and space debris impact also put their stability to a severe test.

Recently, academician Yu Shuhong's team at the Chinese University of Science and Technology has developed a new polyimide - nano-mica composite film material for space protection applications, which adopts a unique bionic design to significantly improve its mechanical properties and tolerance to extreme environments in space. Inspired by the "brick-mud" layer structure of natural mother-of-pearl, the researchers have cleverly designed and constructed a polyimide-mica nanocomposite film with a double-layer pearl-like layer structure, so that the top layer is distributed with denser mica nanosheets, and with the advantages of the intrinsic properties of mica and the most constructed unit, the mechanical properties of the material are effectively improved while the top layer is more resistant to atoms. At the same time, the resistance of the top layer to atomic oxygen, ultraviolet radiation and space debris has also been significantly improved.

The researchers used mica nanosheets with excellent mechanical properties and UV shielding function, which can be prepared in macro quantities, as the building blocks and co-assembled with polyimide precursors to obtain polyimide-mica nanocomposite films, using the superior intrinsic properties of mica to compensate for the deficiencies of polyimide. In this study, the researchers constructed a polyimide-mica nanocomposite film with a double-layer pearl-like layer structure by changing the composition ratio and using a combination of spraying and thermal curing method, which resulted in a denser mica nanosheet in the top layer. This design strategy not only achieves effective improvement of the mechanical properties of the material, but also provides higher resistance to atomic oxygen, UV radiation and space debris on its upper surface.

It was shown that the tensile strength, Young's modulus and surface hardness of this new bionanocomposite film were 125 MPa, 2.2 GPa and 0.37 GPa, respectively, which were 45%, 100% and 68% higher than those of pure polyimide film. Due to the unique bilayer mother-of-pearl-like structure and the inherent performance advantages of mica nanosheets, the resulting bilayer polyimide-mica composite films exhibit superior atomic oxygen tolerance, which is significantly better than pure polyimide films, polyimide-mica composite films with single-layer mother-of-pearl-like structure and previously reported polyimide based composites. In addition, its UV aging resistance (313 nm) and high temperature stability (380 °C) are also significantly improved compared to pure PI films.

This polyimide-mica nanocomposite film with a bilayer mother-of-pearl-like structure is expected to replace the existing polyimide-based composite film materials as an effective new outer protective material for spacecraft and thus for use in low orbit environments. The unique design strategy of the bilayer mother-of-pearl-like structure proposed in this study also provides new ideas for the design and construction of other high-performance nanocomposites.