Huang Weina’s presentation is really eye-opening, especially her discussion on the digitalization of the whole engine design and development process.

She mentioned that “digital engineering” has already been adopted by the US air force as part of the “third offset strategy”, which aims to significantly shorten development cycles and costs to out-innovate peer competitors. She cited the T7A and F35 projects as examples wherein “digital engineering” reduced assembling time by 80%, software development time by 50%, upgrading costs by 81%, maintenance costs by 49%, wind tunnel test time by 20 months, while improving engineering quality by 75%.

She also mentioned that digital (Aerodynamic) models, digitalized project management and the application of AI now enable American developers to chose from thousands rather than dozens of candidate designs, compare lifecycle cost-benefits with high accuracy and reliability, and leverage AI inference based on vast historical data to expedite and optimize designs. Such revolution would provide the US a huge advantage against anyone still following traditional design and development techniques and project management modalities.

It is clear to her that America already has the first-mover advantage in this “digital engineering” revolution and China has to catch up or risk seeing the “US lead being enlarged rather than reduced”. She mentioned that the digital revolution had been experimented in the ongoing WS19 project, bringing the project ahead of schedule and achieving a 25% reduction in test and development (“试制” in her words) cycle. However, China’s progress in this direction is still experimental and partial and a systematic digital transition would require the participation of not only design bureaus and factories, but also civilian partners and suppliers.

A most interesting anecdote she mentioned was that she consulted Huawei experts on digitalization and data analysis, and she emphasized at the end of her presentation that digital revolution in the aerospace industry hinges upon China’s overall progress in digitalization.

An immediate thought that hit me hearing her words is that there is probably a serious risk for America’s offset strategy to succeed in the aerospace sector. China does have a significant disadvantages in digital and electronic technologies at the moment and America clearly bends over containing China tech-wise. If the future of aerospace industries really depends on digital competitiveness, and the hopeless gaps between ChatGPT and Baidu, Alpha-Go and China’s own Go AI, or TSMC and SMIC continue to show no convincing signs of being narrowed, it would be very likely that America would maintain a formidable military tech lead in the foreseeable future (say 3-5 decades) than otherwise.

She mentioned that “digital engineering” has already been adopted by the US air force as part of the “third offset strategy”, which aims to significantly shorten development cycles and costs to out-innovate peer competitors. She cited the T7A and F35 projects as examples wherein “digital engineering” reduced assembling time by 80%, software development time by 50%, upgrading costs by 81%, maintenance costs by 49%, wind tunnel test time by 20 months, while improving engineering quality by 75%.

She also mentioned that digital (Aerodynamic) models, digitalized project management and the application of AI now enable American developers to chose from thousands rather than dozens of candidate designs, compare lifecycle cost-benefits with high accuracy and reliability, and leverage AI inference based on vast historical data to expedite and optimize designs. Such revolution would provide the US a huge advantage against anyone still following traditional design and development techniques and project management modalities.

It is clear to her that America already has the first-mover advantage in this “digital engineering” revolution and China has to catch up or risk seeing the “US lead being enlarged rather than reduced”. She mentioned that the digital revolution had been experimented in the ongoing WS19 project, bringing the project ahead of schedule and achieving a 25% reduction in test and development (“试制” in her words) cycle. However, China’s progress in this direction is still experimental and partial and a systematic digital transition would require the participation of not only design bureaus and factories, but also civilian partners and suppliers.

A most interesting anecdote she mentioned was that she consulted Huawei experts on digitalization and data analysis, and she emphasized at the end of her presentation that digital revolution in the aerospace industry hinges upon China’s overall progress in digitalization.

An immediate thought that hit me hearing her words is that there is probably a serious risk for America’s offset strategy to succeed in the aerospace sector. China does have a significant disadvantages in digital and electronic technologies at the moment and America clearly bends over containing China tech-wise. If the future of aerospace industries really depends on digital competitiveness, and the hopeless gaps between ChatGPT and Baidu, Alpha-Go and China’s own Go AI, or TSMC and SMIC continue to show no convincing signs of being narrowed, it would be very likely that America would maintain a formidable military tech lead in the foreseeable future (say 3-5 decades) than otherwise.

Huang Weina, the chief engineer of ws-19, gave the data of WS19, the thrust of the engineering prototype is 10 tons, and the thrust-to-weight ratio is 10. At the same time, the thrust of ws-13 is similar to that of RD33.

And confirmed the existence of the legendary 9-ton thrust WS-21.

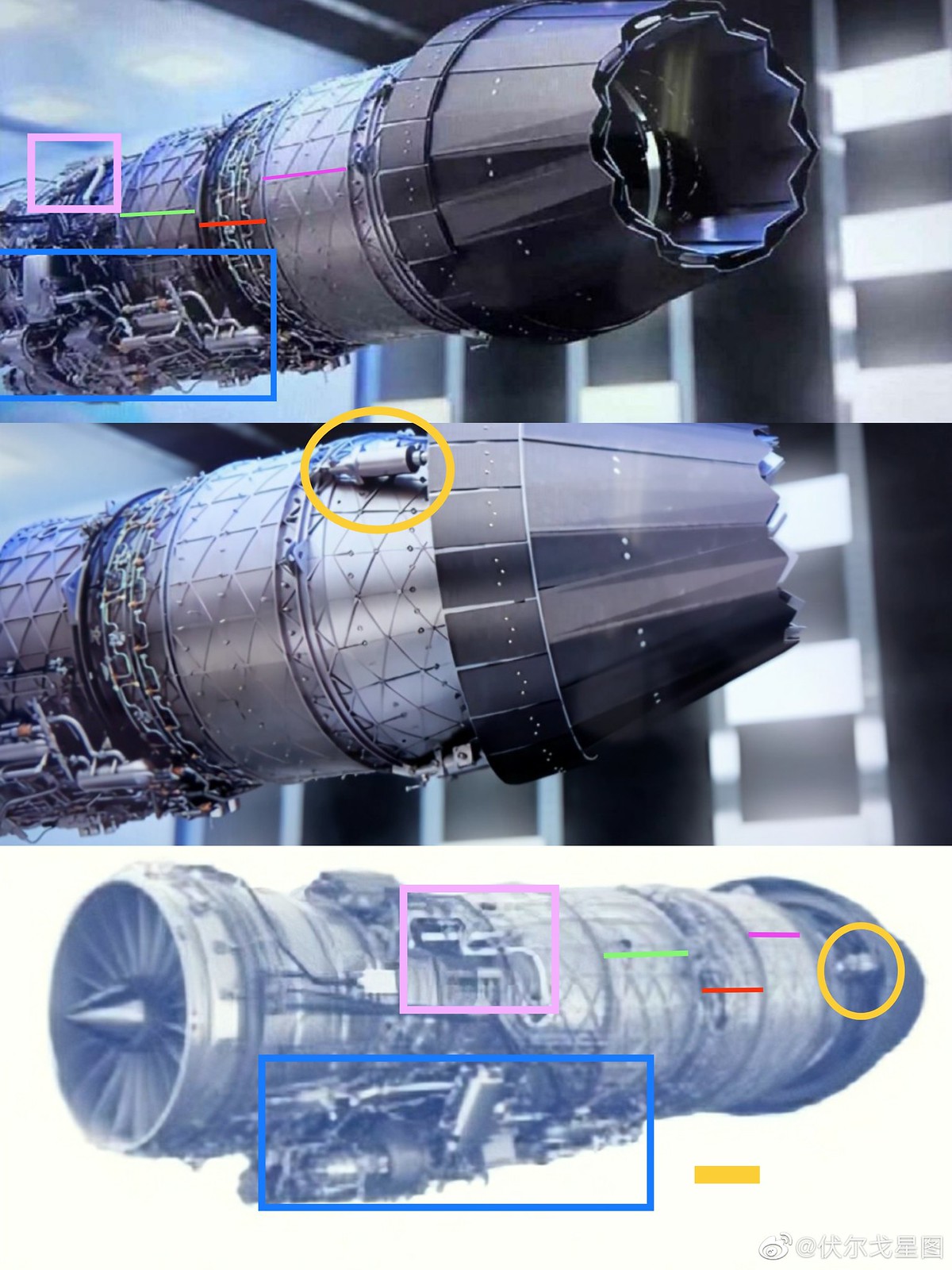

View attachment 106778