Hypergolic engines will be around as long as China is doing manned lunar missions. Those m''fers are the only engines that will absolutely without question ignite after spending some time on the harsh lunar surface. That's why I fear for the safety of the astronauts riding the spacex hls.They have been prioritising cost-efficient platforms, so not for another 5 years until the reusable rockets become fully operational.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

China's Space Program Thread II

- Thread starter Blitzo

- Start date

by78

General

Galatic Energy debuts Ceres-2 and Pallas-2 launch vehicles at Zhuhai Airshow.

Ceres-2 is a 100-ton four-stage commercial launch vehicle:

– Three solid stages + Liquid upper stage

– Fairing diameter: 2.35m or 2.9m

– Take-off weight: 98 tons

– Payload capacity: 1.6 tons to LEO

Pallas-2 heavy reusable launch vehicle:

– Diameter: 3.8m

– Length: 66m

– Fairing diameter: 5.2m

– Takeoff weight: 1196 tons

– Takeoff thrust: 1600 tons

– Payload capacity: 30 tons to LEO (@200km)

– Optional Eros upper stage for deep space exploration

The maiden launch of Ceres-2 is set for June of this year. Interestingly, an electromagnetically launched variant is planned.

by78

General

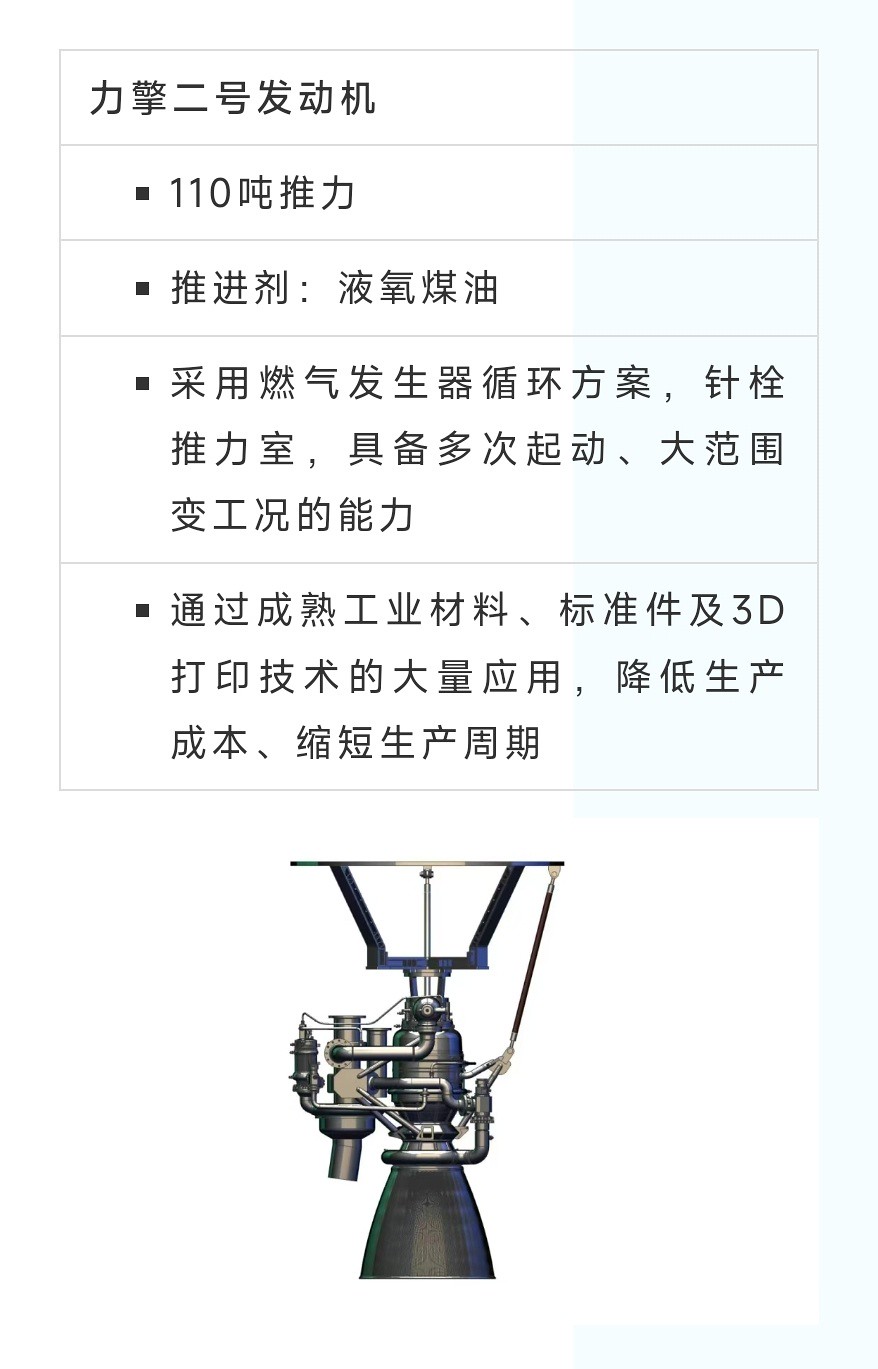

Zhongke's resuable Liqing-1 and Liqing-2 engines (thrust specs upgraded to 30 tons and 110 tons, respectively), .

As scheduled, Zhongke has just delivered the first Liqing-2 engine.

Lethe

Captain

The maiden launch of Ceres-2 is set for June of this year. Interestingly, an electromagnetically launched variant is planned.

Are we talking about something like the SpinLaunch concept here, a more "traditional" linear mass driver as depicted in the following documentary, or something else?

by78

General

Are we talking about something like the SpinLaunch concept here, a more "traditional" linear mass driver as depicted in the following documentary, or something else?

I'm not sure. The brief mention in the text is all I have.

by78

General

Zhongke/CAS Space has completed static load testing on Lijian-2's 1st-stage liquid oxygen tank.

The chairman of Zhongke that the maiden flight of Lijian-2 is scheduled for September of this year.

by78

General

A follow-up paper on China's astroid defense project. We now have a clearer timeline of the planned technology verification test: it is to be conducted from 2027 to 2029 on the target astroid 2015 XF261.

The State Administration of Science, Technology and Industry for National Defense is for the asteroid defense system currently under development.

Spacesail project signed MOU with Malaysian satellite company MEASAT to bring LEO satellite internet to Malaysians.

by78

General

Speaking of replica lunar soil. China has been using simulated lunar soil (produced based on samples of real lunar soil samples) to explore ways to build permanent structures on the Moon. Some of the research results have been published in an English-language paper titled .

Simulated lunar soil is highly similar to real lunar soil in physical properties, mineral composition and chemical properties. Simulated lunar soil-based composite materials are based on simulated lunar soil and are formed into building materials with excellent performance by adding different additives and process treatment.

According to different reinforcement and toughening mechanisms, simulated lunar soil-based composite materials can be divided into many types, including sintered composite materials, geopolymer composite materials, cement-based composite materials, polymer composite materials and fiber-reinforced composite materials.

Sintered composite materials are ultra-high strength building materials formed by phase change of simulated lunar soil powder through high-temperature sintering. This method can achieve 100% in-situ resource utilization and is one of the most promising materials in the construction of lunar bases.

Geopolymer composite materials use alkali-activated solutions to react with silicon-aluminum materials in simulated lunar soil to form a three-dimensional network inorganic polymer. This material can solidify at low temperatures and has good chemical stability and mechanical properties.

Cement-based composite materials are building materials that are improved by referring to the traditional cement concrete preparation process and combining the characteristics of lunar soil. In theory, the water resource problem can be solved by extracting water ice from the lunar polar regions.

Polymer composite materials are building materials formed by mixing thermoplastic polymers, bio-organic polymers, etc. as binders with simulated lunar soil. This material has good formability and plasticity and is suitable for various complex building structures.

Fiber-reinforced composite materials are fiber materials (such as basalt fiber, carbon fiber, etc.) added to simulated lunar soil-based composite materials to significantly improve the mechanical properties and crack resistance of the materials. Its mechanical properties are very excellent, and its compressive strength, tensile strength and flexural strength are significantly improved compared to composite materials without fiber addition.

Special treatment and protection of building materials are required to ensure their stable existence and performance on the moon. Mixing and molding building materials in a microgravity environment is also a technical challenge. The service performance of the lunar base includes thermal performance, radiation shielding and impact resistance. In order to ensure the structural availability of the lunar base, it needs to be fully tested and evaluated. Including mechanical performance testing, durability testing, environmental adaptability testing, etc.

Illustrations from an on in situ construction of lunar habitat. The paper explores using concentrated sunlight to sinter lunar soil into durable construction material with which to build permanent structures.

Abstract: Solar in-situ sintering of lunar soil can effectively realize the in-situ utilization of lunar resources, and is expected to be one of the most potential processes for lunar base construction. In this study, the test system of solar concentrating die sintering based on HUST-1 simulated lunar soil was set up. The surface radiation and solid heat transfer in the process of solar concentrating sintering were calculated by COMSOL, and the initial test of sintering under atmospheric and vacuum environment was carried out. The simulation results show that when the solar irradiance is 1368 W/m2, the temperature in the mold can reach 1100℃, which meets the dynamic requirements of lunar soil sintering. The experimental results show that the sintering temperature is the key process parameter of lunar soil sintering in solar concentrator mold. When the temperature in the mold reaches 800℃, the simulated lunar soil solid-state sintering starts. Due to the difficulty of heat preservation caused by the scattering of sunlight by suspended particles in the Earth's atmosphere and the rapid heat dissipation in the sintering stage at high temperature, the formed blocks have low strength. Therefore, it is necessary to further optimize the test system to explore the densification mechanism of simulated lunar soil by solar concentrating sintering.

Last edited:

by78

General

A KZ-1A solid rocket successfully launched Haishao-1 (海哨一号/Sea Sentinel 1) remote sensing satellite into orbit. The KZ-1A used in this launch is upgraded from previous KZ-1As. It has an enlarged fairing (increased from 1.4m to 1.8m in diameter) and a larger payload capacity to LEO (increased from 300kg to 450kg). Haishao-1, also known as AIRSAT-08, is an ultra-low-orbit X-band synthetic aperture radar with a resolution of less than 1 meter.

Video footage from Haishao-1/AIRSAT-08 captured using its X-band synthetic aperture radar.