Brumby

Major

I wonder if he even understands what he is saying, basically a nuclear powered sub and a conventional diesel powered sub has complete different energy envelopes so if you try to adopt various technology from a nuclear powered sub it would drain a diesel electric sub dry like the pump jet technology which I had questioned here and other forums coming to the same conclusion.

Pump jets are quiet when the screw is spinning at high speed but it has very little effect during low speed but requires more energy since the screw diameter would be smaller then conventional open screws. This is troublesome for a diesel electric powered sub since they are energy strapped forcing the sub to snorkel more often which completely compromise the stealth element completely defeating the reason in equipping a pump jet bell in the first place.

An article from Submarine matters addressing the issue of pump jet on the Australian design.

Since writing of April 29, 2016, I’ve been puzzling about what is technically new to make a pump jet viable on an SSK viable.

A central problem is that there is a correlation between pump jets and large nuclear submarines. Only companies (or countries) that developed pump jets for nuclear subs were in a position to then develop them for SSKs.

Until recently the weight of steel or other metal alloys may have made a pump jet too heavy for a Barracuda (at the smaller end of the SSN scale) or the Shortfin large SSK derivative. Still further lightening may be necessary before a pump jet is viable for Shortfin.

From looking at the sources in the BACKGROUND (below) it seems that using alloy and/or epoxy fibre composite for a pump jet's rotor shaft, rotors, stators and the duct/shroud has many advantages including

- providing a better power to weight ratio for the sub

- not unbalancing the sub

- a fully composite duct gives off a minimum magnetic signature

- composite duct also reduces acoustic signature

- pump jets are low maintenance

- all in all, the above help make a pump jet viable for a small SSN or large SSK.

A rotor (brown) and stator (dull silver) can be seen in this pump jet.

BACKGROUND

[Page 27] Although recent designs of composite propeller systems is classified, the use of modern composites manufacturing allows for continuous fibres to be aligned with major hydrodynamic and centripetal forces. …The use of composites is now is now being introduced for propeller shafts on large ships (frigates and destroyers) where they account for 2% (100-200 tons) of total ship weight.

This for the UK Royal Institution of Naval Architects on page 1 explains meaning of composite:

“A composite material is a material that consists of two components: the fibres and the matrix…The fibres are the part of the composite material that contributes to the strength whilst the matrix holds the fibres together.”

See on the benefits of pump jet propulsor for the Astute SSNs.

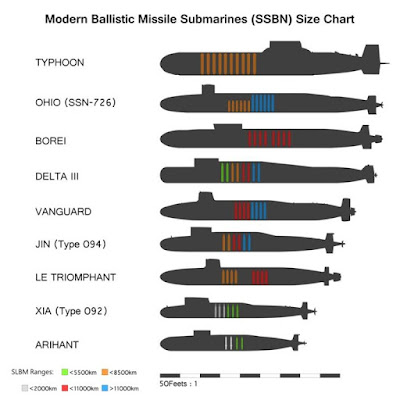

As can be seen above several nuclear subs lack pump jets because they lacked (or lack) pump jet technology. It seems pump jets cannot be retrofitted. (SSBN diagram courtesy )